- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Ergonomics Open Journal

(Discontinued)

ISSN: 1875-9343 ― Volume 11, 2018

A Mathematical Model For Assembly Line Balancing Problem Type 2 Under Ergonomic Workload Constraint

Olcay Polat*, Özcan Mutlu, Elif Özgormus

Abstract

Object:

Assembly lines are one of the essential parts of manufacturing systems that influence the overall cost and efficiency. The productivity of human resource in assembly lines directly affects the efficiency of the lines in practice.

Method:

Because of the heavy physical workloads along with monotonous body postures, the workers are dealing with low performance and Work-related Musculoskeletal Disorders (WMSDs). WMSDs result in high compensation costs for companies and totally decrease the life quality of the workers. In order to improve the efficiency of assembly lines, the companies should not only consider cycle time and precedence constraints, but also physical workloads of the stations. This paper addresses Assembly Line Balancing Problem (ALBP) Type 2 where the number of workstation lines is known. The main objective is balancing the cycle time and physical workload of the stations simultaneously. Rapid Entire Body Assessment (REBA) method from the literature is proposed to determine workload of operations.

Result:

A goal programming model is developed to solve the problem and a well-known small sized benchmark problem instance is used to illustrate the methodology.

Article Information

Identifiers and Pagination:

Year: 2018Volume: 11

First Page: 1

Last Page: 10

Publisher Id: TOERGJ-11-1

DOI: 10.2174/1875934301811010001

Article History:

Received Date: 02/4/2018Revision Received Date: 21/05/2018

Acceptance Date: 2/06/2018

Electronic publication date: 29/06/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: (https://creativecommons.org/licenses/by/4.0/legalcode). This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this authors at the Department of Industrial Engineering, Pamukkale University, 20160, Denizli, Turkey, Tel: +905064162900; Fax: +902582963262; E-mail: opolat@pau.edu.tr

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 02-4-2018 |

Original Manuscript | A Mathematical Model For Assembly Line Balancing Problem Type 2 Under Ergonomic Workload Constraint | |

1. INTRODUCTION

An assembly line consists of workstations connected by a conveyor belt or a similar material handling equipment. At each workstation, various operations necessary to assemble a product are performed [1Mutlu Ö, Özgörmüş E. A fuzzy assembly line balancing problem with physical workload constraints. Int J Prod Res 2012; 50(18): 5281-91.

[http://dx.doi.org/10.1080/00207543.2012.709647] ]. In this production system, the main problem is to distribute tasks among workstation so that the operation time of workstations does not exceed the predetermined cycle time and the precedence relations between tasks are not violated [2Becker C, Scholl A. A survey on problems and methods in generalized assembly line balancing. Eur J Oper Res 2006; 168: 694-715.

[http://dx.doi.org/10.1016/j.ejor.2004.07.023] ]. This is called the Assembly Line Balancing Problem (ALBP).

There are so many researchers who studied the ALBP in many different ways. Most of the studies are focused on Simple assembly Line Balancing Problem (SALBP) where the performance measure is either minimizing the number of stations or the cycle time. There are two basic types of the SALB problem. The type I (SALB-1) problem concerns allocating tasks to stations in the predefined cycle time by minimizing number of stations. The type II (SALB-2) problem concerns allocating tasks to a number of stations by minimizing the cycle time [3Scholl A. Balancing and sequencing of assembly lines 1999.

[http://dx.doi.org/10.1007/978-3-662-11223-6] -5Polat O, Kalayci CB, Mutlu Ö, Gupta SM. A two-phase variable neighbourhood search algorithm for assembly line worker assignment and balancing problem type-II: An industrial case study. Int J Prod Res 2016; 54(3): 722-41.

[http://dx.doi.org/10.1080/00207543.2015.1055344] ]. Further analysis and reviews of SALB problems can be found in the following articles [6Scholl A, Becker C. State-of-the-art exact and heuristic solution procedures for simple assembly line balancing. Eur J Oper Res 2006; 168(3): 666-93.

[http://dx.doi.org/10.1016/j.ejor.2004.07.022] ], [7Boysen N, Fliedner M, Scholl A. A classification of assembly line balancing problems. Eur J Oper Res 2007; 183(2): 674-93.

[http://dx.doi.org/10.1016/j.ejor.2006.10.010] ]: and [8Boysen N, Fliedner M, Scholl A. Assembly line balancing: Which model to use? Int J Prod Econ 2008; 111: 509-28.

[http://dx.doi.org/10.1016/j.ijpe.2007.02.026] ].

The productivity of assembly lines is directly affected by human resource in practice. Since assembly line workers are subject to repetitive motions and heavy work load, their performances fluctuate and their health can be influenced negatively. “Monotonous body postures during repetitive jobs negatively affect assembly-line workers with the developing of Work-related Musculoskeletal Disorders (WMSDs)” [9Rajabalipour Cheshmehgaz H, Haron H, Kazemipour F, Desa MI. Accumulated risk of body postures in assembly line balancing problem and modeling through a multi-criteria fuzzy-genetic algorithm. Comput Ind Eng 2012; 63(2): 503-12.

[http://dx.doi.org/10.1016/j.cie.2012.03.017] ]. These problems decrease the quality of life the workers and result in high medical expenditures for the company [10Kalınkara V, Özkaya K, Polat O. Mobilya Sektörü Çalışanlarında Fiziksel Zorlanmanın Belirlenmesi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 1-12.

[http://dx.doi.org/10.21923/jesd.82230] , 11Polat O, Mutlu Ö, Çakanel H, Doğan O, Özçetin E, Şen E. Bir Mobilya Fabrikasında Çalışan İşçilerin Çalışma Duruşlarının REBA Yöntemi ile Analizi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 263-8.

[http://dx.doi.org/10.21923/jesd.41742] ]. Therefore, the physical workload and ergonomical conditions of the stations should be optimized with the cycle time or precedence constraint simultaneously in assembly lines [1Mutlu Ö, Özgörmüş E. A fuzzy assembly line balancing problem with physical workload constraints. Int J Prod Res 2012; 50(18): 5281-91.

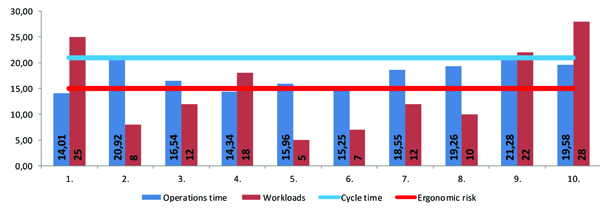

[http://dx.doi.org/10.1080/00207543.2012.709647] ]. For example in Fig. (1 ), all of the workstation have almost equal station times however the distribution of the workloads among workstations are unbalanced and the worloads of 4 workstations are above the ergonomic risk level (red line).

), all of the workstation have almost equal station times however the distribution of the workloads among workstations are unbalanced and the worloads of 4 workstations are above the ergonomic risk level (red line).

|

Fig. (1) Assembly line balancing without considering workloads and ergonomic risk levels. |

In this study, the type II (SALB-2) problem is addressed concerning the health and safety aspects. In spite of the wide research in ALBP, the number of papers that take into account ergonomical factors in the literature is In this study, We propose a model that aims to balance the overall physical workload for each workstation by using REBA (Rapid Entire Body Assessment). The rest of the paper is organized as follows: in Section 2, the literature review for assembly line balancing problem under physical work load is presented. The methods of evaluating physical workload is addressed and REBA is introduced in Section 3. Mixed Integer programming model is given in section 4. A randomly generated problem instance is solved in next section in order to validate the model. Finally, concluding remarks and future research directions are mentioned in the last section.

2. LITERATURE REVIEW

Assembly line balancing problems that incorporate ergonomical factors have recently attracted many researchers. According to Lin, Drury [12Lin L, Drury CG, Kim SW. Ergonomics and quality in paced assembly lines. Hum Factors Ergon Manuf Serv Ind 2001; 11(4): 377-82.

[http://dx.doi.org/10.1002/hfm.1020] ], ergonomical factors has great influence in the quality of the product and the motivation of workers. Yeow and Nath Sen [13Yeow PHP, Nath Sen R. Productivity and quality improvements, revenue increment, and rejection cost reduction in the manual component insertion lines through the application of ergonomics. Int J Ind Ergon 2006; 36(4): 367-77.

[http://dx.doi.org/10.1016/j.ergon.2005.12.008] ] have improved the ergonomical conditions of assembly lines and observed that the production cost has decreased, the efficiency and the level of quality has increased.

Studies in the field of ergonomics and occupational health have shown that excessive workload is one of the main reasons for work-related injuries. For instance, Carnahan, Norman [14Carnahan B, Norman B, Redfern M. Incorporating Physical Demand Criteria into Assembly Line Balancing. IIE Trans 2001; 33(10): 875-87.

[http://dx.doi.org/10.1080/07408170108936880] ] investigated three line balancing heuristics (a ranking heuristics, a combinatorial genetic algorithm, and a problem space genetic algorithm) that incorporate physical demand criteria to solve the problem. They aimed to minimize the cycle time and the maximum manual gripping demands required by the workers. Battini, Faccio [15Battini D, Faccio M, Persona A, Sgarbossa F. New methodological framework to improve productivity and ergonomics in assembly system design. Int J Ind Ergon 2011; 41(1): 30-42.

[http://dx.doi.org/10.1016/j.ergon.2010.12.001] ] analyzed how ergonomics and assembly system design techniques are intimately related and developed a new theoretical framework that takes into account technological variables (related to work times and methods), environmental variables (i.e. absenteeism, staff turnover, work force motivation) and ergonomics evaluations (i.e. human diversity). Di Benedetto and Fanti [16Di Benedetto R, Fanti M. An integrated tool to support engineers for WMSDs risk assessment during the assembly line balancing. Work 2012; 41(Suppl. 1): 2329-33.

[PMID: 22317063] ] presented a software tool named ErgoAnalysis that makes it easy to control the whole production process and produces a Risk Index for the actual work tasks in an assembly line. Deng and Lin [17Deng Q, Lin J. Task Difficulty Balancing Analysis in Assembly Line Balancing. Adv Sci Lett 2012; 5(2): 745-8.

[http://dx.doi.org/10.1166/asl.2012.1811] ] proposed RULA method to measure the difficulty of each task element in each work station. Al-Zuheri, Xing [18Al-Zuheri A, Xing K, Luong L. Mathematical modelling for process design of walking worker assembly line in productivity and ergonomics perspectives. International Journal of Industrial and Systems Engineering 2013; 14(1): 104-37.

[http://dx.doi.org/10.1504/IJISE.2013.052923] ] studied ergonomical assembly line balancing problem for walking workers and improved the efficiency of the line. Pulkurte, Masilamani [19Pulkurte R, Masilamani R, Sonpatki S, Dhake R. Cycle time reduction in assembly line through layout improvement, ergonomics analysis and lean principles. Inter J of Applied Sci and Eng Res 2014; 3(2): 455463.] mainly focused on improving overall efficiency of multi-model assembly line by identifying and eliminating non-value added activities. Furthermore, REBA is used to analyze the posture of workers to eliminate operator movements.

The main reason of Work-related Musculoskeletal Disorders (WMSDs) is monotonous body postures during repetitive jobs [20Özkaya K, Polat O, Kalınkara V. Physical Workload Assessment of Workers in Furniture Industry Using the OWAS Method. The Ergonomics Open Journal 2018; 1-15. In Press]. Rajabalipour Cheshmehgaz, Haron [9Rajabalipour Cheshmehgaz H, Haron H, Kazemipour F, Desa MI. Accumulated risk of body postures in assembly line balancing problem and modeling through a multi-criteria fuzzy-genetic algorithm. Comput Ind Eng 2012; 63(2): 503-12.

[http://dx.doi.org/10.1016/j.cie.2012.03.017] ] developed a model that enables to change worker’s body postures regularly. They used fuzzy goal programming and an appropriate genetic algorithm was developed to deal with the model.

There are some studies that considers “physical workload” as an extra constraint in design of ergonomical assembly lines. For instance, Choi [21Choi G. A goal programming mixed-model line balancing for processing time and physical workload. Comput Ind Eng 2009; 57(1): 395-400.

[http://dx.doi.org/10.1016/j.cie.2009.01.001] ] proposed a zero-one goal-programming model that combines the overload of processing time and physical workload with various risk elements. Otto and Scholl [22Otto A, Scholl A. Incorporating ergonomic risks into assembly line balancing. Eur J Oper Res 2011; 212(2): 277-86.

[http://dx.doi.org/10.1016/j.ejor.2011.01.056] ] introduced a two stage model that takes into account ergonomical risks of work places. In the first stage, line was balanced without considering ergonomical risks and then in the second stage, line was re-balanced considering ergonomic risk factors by using tabu search algorithm. Xu, Ko [23Xu Z, Ko J, Cochran DJ, Jung M-C. Design of assembly lines with the concurrent consideration of productivity and upper extremity musculoskeletal disorders using linear models. Comput Ind Eng 2012; 62(2): 431-41.

[http://dx.doi.org/10.1016/j.cie.2011.10.008] ] developed a linear model to link work-worker assignment to the upper extremity ergonomic measures based on the guideline from American Conference of Governmental Industrial Hygienists. The case studies of this paper showed that the new model could effectively balance and control exposure levels in the upper extremity while not significantly decreasing line efficiency. Mutlu and Özgörmüş [1Mutlu Ö, Özgörmüş E. A fuzzy assembly line balancing problem with physical workload constraints. Int J Prod Res 2012; 50(18): 5281-91.

[http://dx.doi.org/10.1080/00207543.2012.709647] ] considered the physical workload of a task as a fuzzy concept and proposed a fuzzy linear programming model for type 1 ALBP. The proposed model was applied to an assembly line balancing problem in a textile company.

Bautista, Batalla [24Bautista J, Batalla C, Alfaro R. Incorporating Ergonomics Factors into the TSALBP.. Advances in Production Management Systems Competitive Manufacturing for Innovative Products and Services 2013; 397: 413-20.] incorporated ergonomic factors to the time and space constrained Assembly Line Balancing Problem for mixed product lines. Kara, Atasagun [25Kara Y, Atasagun Y, Gökçen H, Hezer S, Demirel N. An integrated model to incorporate ergonomics and resource restrictions into assembly line balancing. Int J Comput Integrated Manuf 2014; 1-11.] proposed a model that is essentially a cost-oriented formulation for ALB under psychological strain, physical strain, worker skills, multiple workers, equipment, working postures and illumination level restrictions. The model minimizes the overall cost associated with operating costs of workforce and resources utilized under the ergonomics and resource restrictions. Battini, Delorme [26Battini D, Delorme X, Dolgui A, Sgarbossa F. Assembly line balancing with ergonomics paradigms: Two alternative methods. IFAC-PapersOnLine 2015; 48(3): 586-91.

[http://dx.doi.org/10.1016/j.ifacol.2015.06.145] ] and Battini, Delorme [27Battini D, Delorme X, Dolgui A, Persona A, Sgarbossa F. Ergonomics in assembly line balancing based on energy expenditure: A multi-objective model. Int J Prod Res 2016; 54(3): 824-45.

[http://dx.doi.org/10.1080/00207543.2015.1074299] ], proposed a multi-objective model based on the energy expenditure, used to estimate the ergonomics level. Battini, Calzavara [28Battini D, Calzavara M, Otto A, Sgarbossa F. The Integrated Assembly Line Balancing and Parts Feeding Problem with Ergonomics Considerations. IFAC-PapersOnLine 2016; 49(12): 191-6.

[http://dx.doi.org/10.1016/j.ifacol.2016.07.594] ] and Battini, Calzavara [29Battini D, Calzavara M, Otto A, Sgarbossa F. Preventing ergonomic risks with integrated planning on assembly line balancing and parts feeding 2018.] integrated ALB and parts feeding problems by incorporating ergonomic considerations. Sgarbossa, Battini [30Sgarbossa F, Battini D, Persona A, Visentin V. Including Ergonomics Aspects into Mixed-Model Assembly Line Balancing Problem. In: Goonetilleke R, Karwowski W, Eds. Proceedings of the AHFE 2016 International Conference on Physical Ergonomics and Human Factors July 27-31, 2016; Cham: Springer International Publishing 991-1001.

[http://dx.doi.org/10.1007/978-3-319-41694-6_94] ] considered mixed-model ALBP under ergonomics aspects. Bautista, Batalla-García [31Bautista J, Batalla-García C, Alfaro-Pozo R. Models for assembly line balancing by temporal, spatial and ergonomic risk attributes. Eur J Oper Res 2016; 251(3): 814-29.

[http://dx.doi.org/10.1016/j.ejor.2015.12.042] ], Bautista, Alfaro-Pozo [32Bautista J, Alfaro-Pozo R, Batalla-García C. Maximizing comfort in Assembly Lines with temporal, spatial and ergonomic attributes. International Journal of Computational Intelligence Systems 2016; 9(4): 788-99.

[http://dx.doi.org/10.1080/18756891.2016.1204125] ] presented a family of line balancing models that consider temporal and spatial attributes while incorporating ergonomic risk attributes.

Akyol and Baykasoğlu [33Akyol SD, Baykasoğlu A. ErgoALWABP: A multiple-rule based constructive randomized search algorithm for solving assembly line worker assignment and balancing problem under ergonomic risk factors 2018.] provided a mathematical model and a heuristic approach for assembly line worker assignment and balancing problem which considers ergonomic risks. Baykasoglu, Tasan [34Baykasoglu A, Tasan SO, Tasan AS, Akyol SD. Modeling and solving assembly line design problems by considering human factors with a real-life application. Hum Factors Ergon Manuf Serv Ind 2017; 27(2): 96-115.

[http://dx.doi.org/10.1002/hfm.20695] ] considered ergonomic factors on assembly line design level and used OCRA method to determine ergonomic risks and rule-based constructive search algorithm to solve the problem. Recently, Tiacci and Mimmi [35Tiacci L, Mimmi M. Integrating ergonomic risks evaluation through OCRA index and balancing/sequencing decisions for mixed model stochastic asynchronous assembly lines. Omega 2018; (2): 1-115. In Press] integrated ergonomic risks evaluation through OCRA index for balancing mixed model stochastic assembly lines. Otto and Battaïa [36Otto A, Battaïa O. Reducing physical ergonomic risks at assembly lines by line balancing and job rotation: A survey. Comput Ind Eng 2017; 111(Suppl. C): 467-80.

[http://dx.doi.org/10.1016/j.cie.2017.04.011] ] examined the optimization models incorporating physical ergonomic risks for assembly line balancing and job rotation scheduling. The ergonomists, production managers and operations researchers interested this subject may read their survey paper in detail.

As seen from above, studies in ALBP literature under ergonomic conditions includes models and solution approaches for Type 1 problem and as long as our knowledge, the related literature for type 2 ALBP is very limited. This study aims to fulfill this gap in the literature by providing a goal programming model to balance the overall physical workload risks through REBA method for each workstation along with minimizing cycle time.

3. THE PHYSICAL WORKLOAD ASSESSMENT

Although the use of mechanization in assembly line systems is increased humans are still the most important part of the assemble lines. Occupational health problems such as Work Related Musculoskeletal Disorders (WMSDs) are verry common among assembly workers. However, the number of Work-related Musculoskeletal Disorders (WMSDs) still increases. Especially in highly industrialized countries, these work related injuries causes costly health care problems. This includes the loss of income, the medical expenses, and the lost of production. To avoid this type of problems, the physical workload and the risk level of job should be assessed in production systems.

The physical workload is a multidimensional concept since there are several factors that affect the measurement process such as (1) demands of work activities (2) the condition of the workplace, and (3) environmental conditions [37Fallentin N, Kilbom Å, Viikari-Juntura E, Wærsted M, Eds. Evaluation of physical workload standards/guidelines from a Nordic perspective. Proceedings of the Human Factors and Ergonomics Society Annual Meeting 2000.

[http://dx.doi.org/10.1177/154193120004403508] ].

Main methods used to assess physical workload are direct methods, observational methods, subjective methods, and other psycho-physiological methods [38Li G, Buckle P. Current techniques for assessing physical exposure to work-related musculoskeletal risks, with emphasis on posture-based methods. Ergonomics 1999; 42(5): 674-95.

[http://dx.doi.org/10.1080/001401399185388] [PMID: 10327891] ]. The most common workload assessment methods are the Job Strain Index (JSI) [39Moore JS, Garg A. The Strain Index: A proposed method to analyze jobs for risk of distal upper extremity disorders. Am Ind Hyg Assoc J 1995; 56(5): 443-58.

[http://dx.doi.org/10.1080/15428119591016863] [PMID: 7754975] ]; the National Institute for Occupational Safety and Health (NIOSH) lifting equation; the Rapid Entire Body Assessment (REBA) [40Hignett S, McAtamney L. Rapid entire body assessment (REBA). Appl Ergon 2000; 31(2): 201-5.

[http://dx.doi.org/10.1016/S0003-6870(99)00039-3] [PMID: 10711982] ]; the rapid upper limp assessment (RULA) [41McAtamney L, Nigel Corlett E. RULA: A survey method for the investigation of work-related upper limb disorders. Appl Ergon 1993; 24(2): 91-9.

[http://dx.doi.org/10.1016/0003-6870(93)90080-S] [PMID: 15676903] ]; the Manual handling Assessment Charts (MAC); and the Assessment of Repetitive Tasks (ART) The selection of suitable method is important since they are intended to measure workloads of the jobs that have certain condions. A recent study of Roman-Liu [42Roman-Liu D. Comparison of concepts in easy-to-use methods for MSD risk assessment. Appl Ergon 2014; 45(3): 420-7.

[http://dx.doi.org/10.1016/j.apergo.2013.05.010] [PMID: 23849897] ] compares these methods with each other and investigates the pros and cons.

In the proposed model, REBA is used to measure the workload of stations since this method enables to analyze various postures adopted by workers. Researchers started to pay more attention to this method for ALBPs [1Mutlu Ö, Özgörmüş E. A fuzzy assembly line balancing problem with physical workload constraints. Int J Prod Res 2012; 50(18): 5281-91.

[http://dx.doi.org/10.1080/00207543.2012.709647] , 19Pulkurte R, Masilamani R, Sonpatki S, Dhake R. Cycle time reduction in assembly line through layout improvement, ergonomics analysis and lean principles. Inter J of Applied Sci and Eng Res 2014; 3(2): 455463., 43Kara Y, Atasagun Y, Peker A, Eds. Montaj Hatlarında Çalışma Duruşlarının REBA Yöntemi ile Analizi ve Ergonomik Risk Değerlendirmesi. 7 Uluslararası İş Sağlığı ve Güvenliği Konferansı; 2014 5 - 7 Mayıs 2014; İstanbul., 44Polat O, Kalayci CB. Ergonomic Risk Assessment of Workers in Garment Industry. Eight International Conference on Textile Science & Economy VIII May 16-21, 2016; 2016.2016.]. REBA is an observational method that is developed to quantify the risk level of various body postures [40Hignett S, McAtamney L. Rapid entire body assessment (REBA). Appl Ergon 2000; 31(2): 201-5.

[http://dx.doi.org/10.1016/S0003-6870(99)00039-3] [PMID: 10711982] ]. The basis of the assessment of the degree of exposure is the aggregate position of the body [45Lasota AM. A Reba-based analysis of packers workload: A case study. Log Forum 2014; 10(1): 87-95.]. Traditional REBA method has six basic steps:

- Observe the worker

- Select the body posture to be analyzed.

- Score the posture.

- Record the score to REBA Table

- Calculate the final REBA score

- Determine the risk level

In summary, after the observation of the worker, a general ergonomical analyze of the job and work environment is proceed. In the calculation step, the body parts are divided into two groups: Neck, Trunk and Leg Analysis (Score A) and Arm and Wrist Analysis (Score B) [40Hignett S, McAtamney L. Rapid entire body assessment (REBA). Appl Ergon 2000; 31(2): 201-5.

[http://dx.doi.org/10.1016/S0003-6870(99)00039-3] [PMID: 10711982] ].

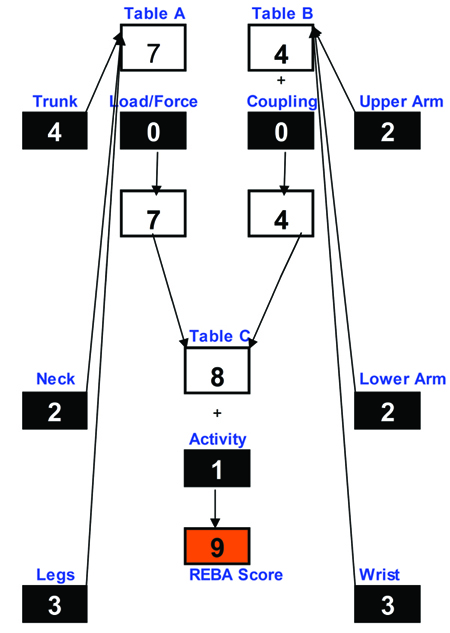

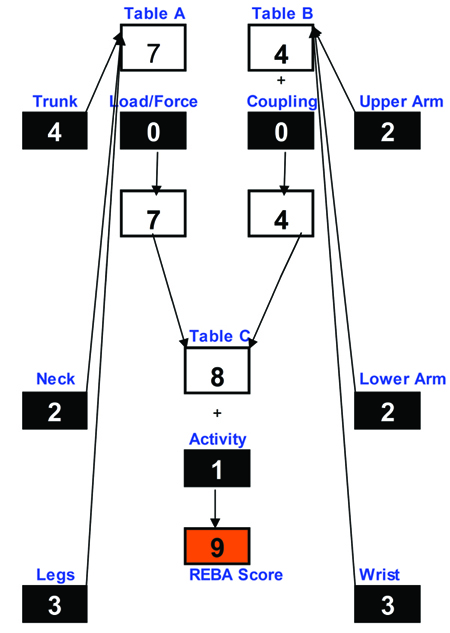

In order to determine Score A, trunk, neck and leg positions during the operations are observed and scored. These scores are converted to Score A by using Table 1 and Forve/Load score.

Then, upper arm, lower arm and wrist positions are investigated and scored. These scores are converted to Score B by using Table 2 and additional coupling score.

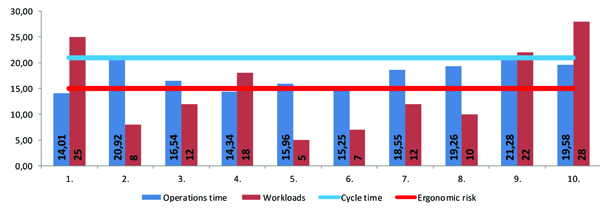

Finally, Score A and Score B combined by using Table 3 and activity score to calculate Score C. Fig. (2 ) presents an example calculation for determination of final REBA score.

) presents an example calculation for determination of final REBA score.

|

Fig. (2) An example REBA assessment worksheet. |

Depending on the case, an activity score is also added to score C in order to calculate final REBA score which is scaled between 1 and 15. Based on the calculated final score, the risk level and actions required for the improvement of working conditions on the assessed position can be classified by using (Table 4).

4. MATHEMATICAL MODEL

The SALBP Type 2 minimizes the cycle time for a given a number of workstations under precedence constraint. A goal programming model is developed by considering following assumptions:

- Paced line with fixed cycle time,

- Deterministic operation times,

- No assignment restrictions besides the precedence constraints,

- Every task is assigned to a workstation

- Some tasks should be assigned to certain workstations because of special equipment and area requirements.

- Exceeding workload limit is allowed but penalized.

- One-sided serial line layout.

- For the assessment of physical workload REBA method is used.

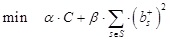

Goal Programming Model:

Operational Set

Operational Set

S Workstation Set

S Workstation Set

Qi Available stations for task i

Pi Set of immediate predecessors of task i in the precedence network

Parameters

ti Operation time of task i

di Physical workload of task i

D Maximum allowed total workload of a station

α Cycle time coefficient

β Penalty coefficient for exceeding workload limit

Decision Variables

C Cycle time

Xsi 1: if task i assigned to station s, 0: otherwise

bs+ Positive deviational variable for exceeding workload limit

bs- Negative deviational variable for staying under workload limit Objective Functions

Objective Functions

|

(1) |

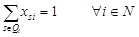

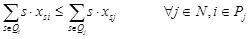

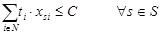

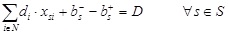

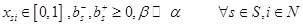

Constraints

|

(2) |

|

(3) |

|

(4) |

|

(5) |

|

(6) |

The objective function in Equation (1) minimizes the number cycle time along with balancing physical workload of workstations. Equation (2) guarantees that every task is assigned to a proper workstation. Equation (3) ensures that the precedence relations between tasks are satisfied. Equation (4) ensures that the total station time does not exceed the cycle time. Equation (5) evaluate total physical workload of a workstation. Finally, Equation (6) defines variable domains.

5. NUMERICAL INVESTIGATION

In order to validate the model, a Killbridge test instance which is consist of 45 tasks, is modified for the problem by including randomly generated physical workloads for each task. Table 5 shows predecessors (P), durations (T) and workloads (W) of each task (i) for Killbridge test instance.

The modified problem instance is solved by using IBM ILOG CPLEX Optimization Studio 12.7.1 for 8 opening workstations. The maximum allowed physical workload level is considered as 10 and 8. Table 6 shows the assignments of the tasks to stations without/with workload constraint. According to results in this table, considering workload constraint increases the cycle time of the line by only 1 unit when the workload limit is set to 10. On the other hand, while workloads of the stations vary between 5 and 13 in first case, considering workload constraint provides more balanced workloads that changes between 8 and 10. When the workload limit set to 8, new cycle time became 72 and positive deviational variable for exceeding workload limit increased to 2 for four stations. However, due to objective model formulation physical workloads are more equally distributed despite the total durations of the stations.

As seen from the results of Killbridge test instance with randomly generated workloads, considering workloads could not only provide a more balanced line but also reduce the risk of work-related musculoskeletal disorders which may result very expensive medical treatment or compensation costs. Therefore, in the assembly line problems, companies should consider the physical workloads of the stations along with cycle time and precedence constraints.

6. CONCLUSION AND FURTHER RESEARCH

Nowadays, the importance of human resource and flexibility under changing conditions are key concepts of competitive environment of industries. Quantitative increment in values does not represent the improvement in efficiency or productivity. For this reason, this paper addresses a goal programming model for assembly line balancing problem (ALBP) type 2 under physical workload constraint. As a solution method in assessment of workloads, rapid entire body assessment (REBA) is proposed. In order to validate the model, a small sized test instance with randomly generated workloads is solved by using CPLEX solver. In the future studies, a real case study should be investigated for determination of the workloads using REBA since the problem is widely encountered in practice. Furthermore, since ALBP is proved to be NP-hard problem, heuristic methodologies can be applied to solve this problem for large problem instances.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Initial findings of this work was presented at The 2015 Northeast Decision Sciences Conference, March 20-22, 2015, Cambridge / MA, USA.

REFERENCES

| [1] | Mutlu Ö, Özgörmüş E. A fuzzy assembly line balancing problem with physical workload constraints. Int J Prod Res 2012; 50(18): 5281-91. [http://dx.doi.org/10.1080/00207543.2012.709647] |

| [2] | Becker C, Scholl A. A survey on problems and methods in generalized assembly line balancing. Eur J Oper Res 2006; 168: 694-715. [http://dx.doi.org/10.1016/j.ejor.2004.07.023] |

| [3] | Scholl A. Balancing and sequencing of assembly lines 1999. [http://dx.doi.org/10.1007/978-3-662-11223-6] |

| [4] | Mutlu O, Polat O, Supciller AA. An iterative genetic algorithm for the assembly line worker assignment and balancing problem of type-II. Comput Oper Res 2013; 40(1): 418-26. [http://dx.doi.org/10.1016/j.cor.2012.07.010] |

| [5] | Polat O, Kalayci CB, Mutlu Ö, Gupta SM. A two-phase variable neighbourhood search algorithm for assembly line worker assignment and balancing problem type-II: An industrial case study. Int J Prod Res 2016; 54(3): 722-41. [http://dx.doi.org/10.1080/00207543.2015.1055344] |

| [6] | Scholl A, Becker C. State-of-the-art exact and heuristic solution procedures for simple assembly line balancing. Eur J Oper Res 2006; 168(3): 666-93. [http://dx.doi.org/10.1016/j.ejor.2004.07.022] |

| [7] | Boysen N, Fliedner M, Scholl A. A classification of assembly line balancing problems. Eur J Oper Res 2007; 183(2): 674-93. [http://dx.doi.org/10.1016/j.ejor.2006.10.010] |

| [8] | Boysen N, Fliedner M, Scholl A. Assembly line balancing: Which model to use? Int J Prod Econ 2008; 111: 509-28. [http://dx.doi.org/10.1016/j.ijpe.2007.02.026] |

| [9] | Rajabalipour Cheshmehgaz H, Haron H, Kazemipour F, Desa MI. Accumulated risk of body postures in assembly line balancing problem and modeling through a multi-criteria fuzzy-genetic algorithm. Comput Ind Eng 2012; 63(2): 503-12. [http://dx.doi.org/10.1016/j.cie.2012.03.017] |

| [10] | Kalınkara V, Özkaya K, Polat O. Mobilya Sektörü Çalışanlarında Fiziksel Zorlanmanın Belirlenmesi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 1-12. [http://dx.doi.org/10.21923/jesd.82230] |

| [11] | Polat O, Mutlu Ö, Çakanel H, Doğan O, Özçetin E, Şen E. Bir Mobilya Fabrikasında Çalışan İşçilerin Çalışma Duruşlarının REBA Yöntemi ile Analizi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 263-8. [http://dx.doi.org/10.21923/jesd.41742] |

| [12] | Lin L, Drury CG, Kim SW. Ergonomics and quality in paced assembly lines. Hum Factors Ergon Manuf Serv Ind 2001; 11(4): 377-82. [http://dx.doi.org/10.1002/hfm.1020] |

| [13] | Yeow PHP, Nath Sen R. Productivity and quality improvements, revenue increment, and rejection cost reduction in the manual component insertion lines through the application of ergonomics. Int J Ind Ergon 2006; 36(4): 367-77. [http://dx.doi.org/10.1016/j.ergon.2005.12.008] |

| [14] | Carnahan B, Norman B, Redfern M. Incorporating Physical Demand Criteria into Assembly Line Balancing. IIE Trans 2001; 33(10): 875-87. [http://dx.doi.org/10.1080/07408170108936880] |

| [15] | Battini D, Faccio M, Persona A, Sgarbossa F. New methodological framework to improve productivity and ergonomics in assembly system design. Int J Ind Ergon 2011; 41(1): 30-42. [http://dx.doi.org/10.1016/j.ergon.2010.12.001] |

| [16] | Di Benedetto R, Fanti M. An integrated tool to support engineers for WMSDs risk assessment during the assembly line balancing. Work 2012; 41(Suppl. 1): 2329-33. [PMID: 22317063] |

| [17] | Deng Q, Lin J. Task Difficulty Balancing Analysis in Assembly Line Balancing. Adv Sci Lett 2012; 5(2): 745-8. [http://dx.doi.org/10.1166/asl.2012.1811] |

| [18] | Al-Zuheri A, Xing K, Luong L. Mathematical modelling for process design of walking worker assembly line in productivity and ergonomics perspectives. International Journal of Industrial and Systems Engineering 2013; 14(1): 104-37. [http://dx.doi.org/10.1504/IJISE.2013.052923] |

| [19] | Pulkurte R, Masilamani R, Sonpatki S, Dhake R. Cycle time reduction in assembly line through layout improvement, ergonomics analysis and lean principles. Inter J of Applied Sci and Eng Res 2014; 3(2): 455463. |

| [20] | Özkaya K, Polat O, Kalınkara V. Physical Workload Assessment of Workers in Furniture Industry Using the OWAS Method. The Ergonomics Open Journal 2018; 1-15. In Press |

| [21] | Choi G. A goal programming mixed-model line balancing for processing time and physical workload. Comput Ind Eng 2009; 57(1): 395-400. [http://dx.doi.org/10.1016/j.cie.2009.01.001] |

| [22] | Otto A, Scholl A. Incorporating ergonomic risks into assembly line balancing. Eur J Oper Res 2011; 212(2): 277-86. [http://dx.doi.org/10.1016/j.ejor.2011.01.056] |

| [23] | Xu Z, Ko J, Cochran DJ, Jung M-C. Design of assembly lines with the concurrent consideration of productivity and upper extremity musculoskeletal disorders using linear models. Comput Ind Eng 2012; 62(2): 431-41. [http://dx.doi.org/10.1016/j.cie.2011.10.008] |

| [24] | Bautista J, Batalla C, Alfaro R. Incorporating Ergonomics Factors into the TSALBP.. Advances in Production Management Systems Competitive Manufacturing for Innovative Products and Services 2013; 397: 413-20. |

| [25] | Kara Y, Atasagun Y, Gökçen H, Hezer S, Demirel N. An integrated model to incorporate ergonomics and resource restrictions into assembly line balancing. Int J Comput Integrated Manuf 2014; 1-11. |

| [26] | Battini D, Delorme X, Dolgui A, Sgarbossa F. Assembly line balancing with ergonomics paradigms: Two alternative methods. IFAC-PapersOnLine 2015; 48(3): 586-91. [http://dx.doi.org/10.1016/j.ifacol.2015.06.145] |

| [27] | Battini D, Delorme X, Dolgui A, Persona A, Sgarbossa F. Ergonomics in assembly line balancing based on energy expenditure: A multi-objective model. Int J Prod Res 2016; 54(3): 824-45. [http://dx.doi.org/10.1080/00207543.2015.1074299] |

| [28] | Battini D, Calzavara M, Otto A, Sgarbossa F. The Integrated Assembly Line Balancing and Parts Feeding Problem with Ergonomics Considerations. IFAC-PapersOnLine 2016; 49(12): 191-6. [http://dx.doi.org/10.1016/j.ifacol.2016.07.594] |

| [29] | Battini D, Calzavara M, Otto A, Sgarbossa F. Preventing ergonomic risks with integrated planning on assembly line balancing and parts feeding 2018. |

| [30] | Sgarbossa F, Battini D, Persona A, Visentin V. Including Ergonomics Aspects into Mixed-Model Assembly Line Balancing Problem. In: Goonetilleke R, Karwowski W, Eds. Proceedings of the AHFE 2016 International Conference on Physical Ergonomics and Human Factors July 27-31, 2016; Cham: Springer International Publishing 991-1001. [http://dx.doi.org/10.1007/978-3-319-41694-6_94] |

| [31] | Bautista J, Batalla-García C, Alfaro-Pozo R. Models for assembly line balancing by temporal, spatial and ergonomic risk attributes. Eur J Oper Res 2016; 251(3): 814-29. [http://dx.doi.org/10.1016/j.ejor.2015.12.042] |

| [32] | Bautista J, Alfaro-Pozo R, Batalla-García C. Maximizing comfort in Assembly Lines with temporal, spatial and ergonomic attributes. International Journal of Computational Intelligence Systems 2016; 9(4): 788-99. [http://dx.doi.org/10.1080/18756891.2016.1204125] |

| [33] | Akyol SD, Baykasoğlu A. ErgoALWABP: A multiple-rule based constructive randomized search algorithm for solving assembly line worker assignment and balancing problem under ergonomic risk factors 2018. |

| [34] | Baykasoglu A, Tasan SO, Tasan AS, Akyol SD. Modeling and solving assembly line design problems by considering human factors with a real-life application. Hum Factors Ergon Manuf Serv Ind 2017; 27(2): 96-115. [http://dx.doi.org/10.1002/hfm.20695] |

| [35] | Tiacci L, Mimmi M. Integrating ergonomic risks evaluation through OCRA index and balancing/sequencing decisions for mixed model stochastic asynchronous assembly lines. Omega 2018; (2): 1-115. In Press |

| [36] | Otto A, Battaïa O. Reducing physical ergonomic risks at assembly lines by line balancing and job rotation: A survey. Comput Ind Eng 2017; 111(Suppl. C): 467-80. [http://dx.doi.org/10.1016/j.cie.2017.04.011] |

| [37] | Fallentin N, Kilbom Å, Viikari-Juntura E, Wærsted M, Eds. Evaluation of physical workload standards/guidelines from a Nordic perspective. Proceedings of the Human Factors and Ergonomics Society Annual Meeting 2000. [http://dx.doi.org/10.1177/154193120004403508] |

| [38] | Li G, Buckle P. Current techniques for assessing physical exposure to work-related musculoskeletal risks, with emphasis on posture-based methods. Ergonomics 1999; 42(5): 674-95. [http://dx.doi.org/10.1080/001401399185388] [PMID: 10327891] |

| [39] | Moore JS, Garg A. The Strain Index: A proposed method to analyze jobs for risk of distal upper extremity disorders. Am Ind Hyg Assoc J 1995; 56(5): 443-58. [http://dx.doi.org/10.1080/15428119591016863] [PMID: 7754975] |

| [40] | Hignett S, McAtamney L. Rapid entire body assessment (REBA). Appl Ergon 2000; 31(2): 201-5. [http://dx.doi.org/10.1016/S0003-6870(99)00039-3] [PMID: 10711982] |

| [41] | McAtamney L, Nigel Corlett E. RULA: A survey method for the investigation of work-related upper limb disorders. Appl Ergon 1993; 24(2): 91-9. [http://dx.doi.org/10.1016/0003-6870(93)90080-S] [PMID: 15676903] |

| [42] | Roman-Liu D. Comparison of concepts in easy-to-use methods for MSD risk assessment. Appl Ergon 2014; 45(3): 420-7. [http://dx.doi.org/10.1016/j.apergo.2013.05.010] [PMID: 23849897] |

| [43] | Kara Y, Atasagun Y, Peker A, Eds. Montaj Hatlarında Çalışma Duruşlarının REBA Yöntemi ile Analizi ve Ergonomik Risk Değerlendirmesi. 7 Uluslararası İş Sağlığı ve Güvenliği Konferansı; 2014 5 - 7 Mayıs 2014; İstanbul. |

| [44] | Polat O, Kalayci CB. Ergonomic Risk Assessment of Workers in Garment Industry. Eight International Conference on Textile Science & Economy VIII May 16-21, 2016; 2016.2016. |

| [45] | Lasota AM. A Reba-based analysis of packers workload: A case study. Log Forum 2014; 10(1): 87-95. |