- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Open Mechanical Engineering Journal

(Discontinued)

ISSN: 1874-155X ― Volume 14, 2020

Design and Experiment of a Replant Crops Separating Garlic Harvester

Zhonglai Tian1, Ying Zhao1, Yongxiang Sui1, Jialin Hou2, *, Qun Sun1, Chong Wang1, Zhenyou Wang1, Ling Zhao1

Abstract

Background:

Garlic is one of the main economic crops in China and the planting area is increasing quickly. But the harvest process of the garlic mainly relies on manual digging, resulting in low harvest efficiency and high cost.

Objective:

In order to improve the efficiency of garlic harvest, and achieve the mechanization of garlic harvest. The study presents a new design of a garlic harvesting machine that can perform automatic processing and deal with the issue of garlic harvesting.

Methods:

Firstly, the three-dimensional model of the whole machine and the key mechanism is established and the parameters of the system are calculated by theoretical calculation. Then, the simulation be made and the design be optimized. Finally, the design was processed into a product. It employs an isolation mechanism and positioned cutting mechanism to isolate garlic and crop stubbles and keep the length of the remaining garlic straw consistent.

Results:

The results of field harvest experiments show that the miss digging rate, miss cutting rate and injury rate of the harvester are as low as 1.23%, 3.13% and 0.68% respectively, and the harvest efficiency is 0.06km2/h.

Conclusion:

The advantages of the harvester such as high harvesting rate, low damage rate, strong adaptability and high versatility, effectively improve the working efficiency, reduce the labor intensity and the harvest cost.

Article Information

Identifiers and Pagination:

Year: 2018Volume: 12

First Page: 67

Last Page: 80

Publisher Id: TOMEJ-12-67

DOI: 10.2174/1874155X01812010067

Article History:

Received Date: 01/3/2018Revision Received Date: 19/03/2018

Acceptance Date: 20/03/2018

Electronic publication date: 30/04/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: (https://creativecommons.org/licenses/by/4.0/legalcode). This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this authors at the School of Mechanical and Electronics Engineering, Shandong Agricultural University, Jialin Hou, No. 61, Daizong Street, Taian City, Shandong Province, China; Tel: +8605388246121; Email: jlhou@sdau.edu.cn

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 01-3-2018 |

Original Manuscript | Design and Experiment of a Replant Crops Separating Garlic Harvester | |

1. INTRODUCTION

Garlic is widely accepted by some population groups for its rich nutrition, special seasoning effects, and health benefits such as anti-cancer effect [1M. Emerald, and P.S. Bisen, "Nutritional and therapeutic potential of garlic and onion (Allium sp.)", Current Nutrition and Food Science, vol. 12, no. 3, pp. 190-199.

[http://dx.doi.org/10.2174/1573401312666160608121954] , 2Y. S. de Queiroz, P. B. Antunes, S. J. V. Vicente, G. R. Sampaio, J. Shibao, D. H. M. Bastos, and E. A. F. da S. Torres, "Bioactive compounds, in vitro antioxidant capacity and Maillard reaction products of raw boiled and fried garlic", Int. J. Food Sci. Technol., vol. 49, no. 5, pp. 1308-1314.]. China is the world's largest garlic cultivation country and contributes 90% of international garlic trade [3F. Haitao, "Analysis of the status quo of pay Haitao harvest mechanization in Jinxiang county garlic", Ara of Agricultural Machinery, vol. 8, p. 8.]. As garlic is useful in a wide range of areas, it has attracted increasing domestic and international attention in recent years. However, due to the limit of special garlic harvest time, the mechanized harvest requirements [4F. Bayat, S. Rezvani, and A.E. Nosrati, "Effect of harvesting time and curing temperature on some properties of Iranian white garlic", Acta Hortic., vol. 877, no. 877, pp. 89-875.] and other factors, the harvest of garlic in China is still using artificial digging, picking and processing, resulting in high labor intensity and low harvest efficiency, limiting the development of garlic cultivation in China.

At present, some developed countries and regions have achieved the mechanized harvest of garlic. But these researches are mainly for the harvest of garlic in a large area of farm and do not have to deal with the issue of small area planting. In 2015, Hebei Agricultural Mechanization Research Institute Co., Ltd. designed a front mounted garlic harvester, with a vibration digging shovel and separation conveyor chain to improve the harvest efficiency, leading to productivity rate greater than 0.2 km2/h and garlic damage rate about 2% [5G. Qinghai, and C. Sigang, "Research and development of front type garlic harvester", Hebei Agricultural Machinery, vol. 12, pp. 13-15.]. In 2016, Xuzhou City Agricultural Machinery Technology Promotion Station developed Yangma HZ20 self-propelled garlic harvester, which has lodging rate of 1% and harvest efficiency about 0.03~0.04 km2/h [6Z. Zhongyu, and W. Jing, "Yanmar HZ20 self-propelled garlic harvester technology and benefit analysis", Agricultural Equipment Technology, vol. 42, no. 2, pp. 36-37.]. In 2016, Shandong Province Institute of Agricultural Machinery developed a small garlic combine harvester, which adopted a crawler chassis and small compact size to ensure convenience. The total loss rate is 2.25% and the productivity rate is 0.035km2/h [7X. Wenyi, Z. Hua, Z. Zhiqi, Z. Jin, and C. Zhongkai, "Design and experiment of small garlic combine", Journal of Agricultural Mechanization Research, vol. 26, no. 2, pp. 1-2.]. There were other designs with varying mobile and collecting mechanism for garlic harvest [8Y. Xiangtao, H. Zhichao, H. Lianglong, and P. Baoliang, "Test and analysis of operational performance of 4DLB-2 type garlic combine harvester", Zhongguo Nongye Daxue Xuebao, vol. 18, no. 4, pp. 183-187.]. These researches are not systematic and continuity, developed a single machine function, the actual harvest effect is poor, not be used into the field to serve the people, so there is large market demand for garlic harvesting machinery.

The design is aimed on solving the issues such as low harvesting efficiency and high damage rate of miniaturized equipment, high cost and low adaptability of large equipment. The study designed a garlic harvester, completed all the garlic harvesting process, and achieved machine miniaturization to adapt to small area planting environment. The results of field harvest experiments showed that the trapping rate, missing rate and injury rate of the harvester are as low as 1.23%, 3.13% and 0.68%, respectively, and the harvest efficiency is 0.06 km2/h. The problems of too large volume of harvester and the inconvenience of operation have been solved by this design and the damage rate effectively reduced.

2. DEVELOPMENT OF THE GARLIC HARVESTER

2.1. Overall Design

2.1.1. Overall Scheme Design

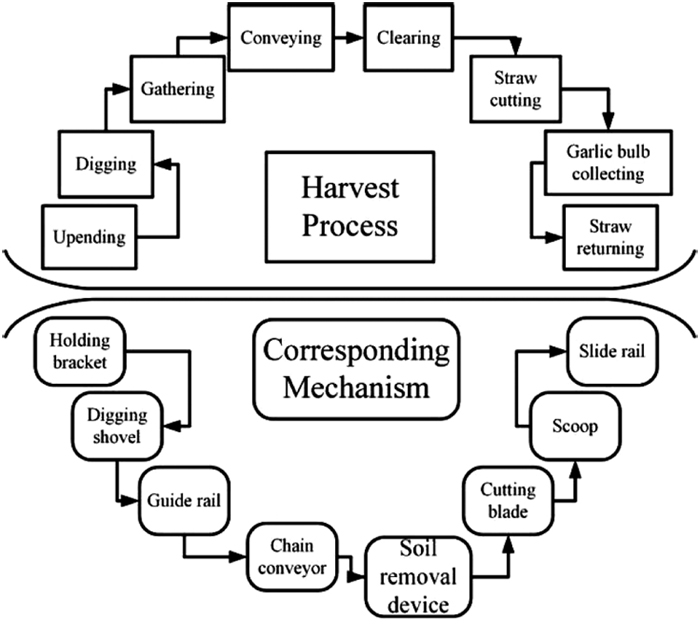

Through the visit to the local farmers, a detailed understanding of garlic harvesting problems, different varieties and different soil conditions were obtained. In the field measurement, the parameters of the soil and garlic growth were collected and analyzed according to the principle of randomness [9W. Xiaoyu, C. Rongjiang, F. Qianqun, F. Qianqun, and C. Zhongkai, "Experimental study on garlic dislocation of wide narrow row planting method of", Agricultural Equipment and Vehicle Engineering, vol. 53, no. 8, pp. 5-8.]. According to analysis of the survey results, the design purpose and ideas have been decided to be developing a garlic harvester, to complete garlic digging, transportation, dust removal, straw cutting, garlic collection etc [10W. Linchong, "Design optimization of garlic harvester", Agricultural Development and Equipment, vol. 2, pp. 19-22.-14F.M. Barrett, "Further work on the development of a simple tractor-mounted yam harvester", Arxiv Cornell University Library, vol. 1068, no. 1, pp. 103-114.], and to achieve mechanized harvest of garlic. The garlic harvest process and mechanization of the program are shown in Fig. (1 ).

).

|

Fig. (1) Garlic harvest process and mechanization progra. |

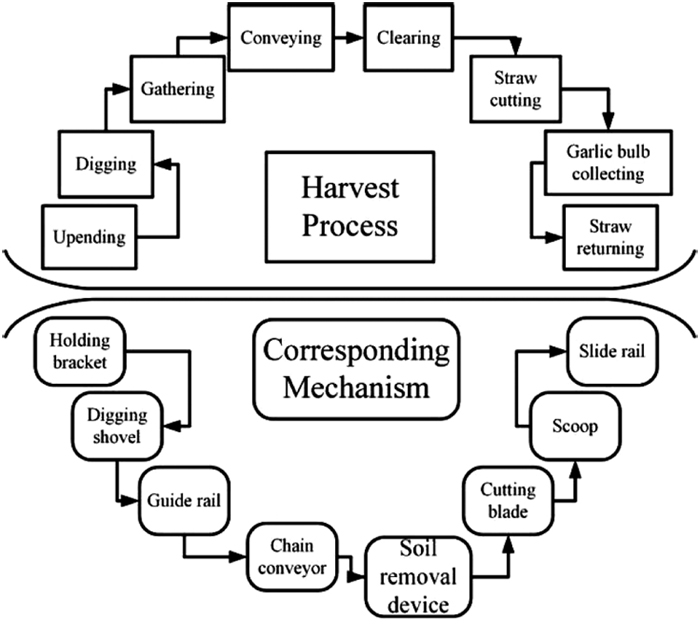

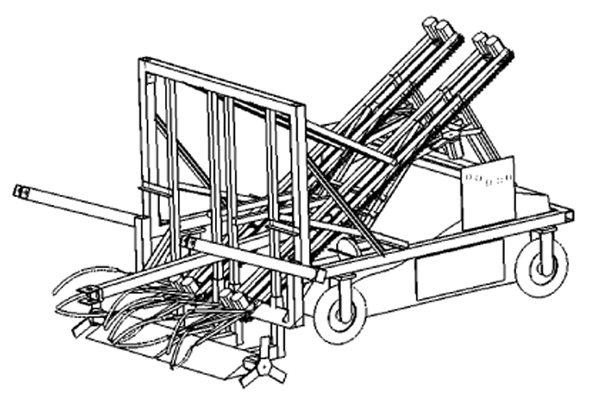

2.2. Design of Mechanical Parts

The functions of the machine determine the structure of the rack. The machine body is supported and guided by load bearing wheel 7, a collecting bin is mounted on main beam 6, the front end is vertically fixed frame 2, and the bottom end of vertical fixture frame is attached to a shovel connecting frame 5. On the two sides of the vertical fixture frame are direction control beams 3 that control the machine travel direction. In the middle is the load-bearing beam 4, used to connect the machine with agricultural machinery. The bottom ends of the vertical fixture racks are attached to the bottom of the clamping conveying chain bracket 1. The rear end of the clamping and conveying frame is connected to a support frame 8. The machine also includes lodging support bracket and garlic straw cutting tool installation bracket [15A.C. Rathinakumari, and D.M. Jesudas, "Design and development of tractor operated onion set planter", Indian Journal of Agricultural Sciences, vol. 85, no. 8, pp. 1038-1041., 16H.M. Akhir, D. Ahmad, I.H. Rukunudin, S. Shamsuddin, and A. Yahya, "Design and development a sweet potato digging device", Pertanika J. Sci. Technol., vol. 22, no. 1, pp. 43-53.]. The rack diagram is shown in Fig. (2 ).

).

|

Fig. (2) Garlic harvester rack. |

The garlic harvester excavation device includes the excavation shovel and the isolation tool, in which the upper shovel is in a smooth spiral design, which is beneficial to reduce the resistance in the excavation process, and helps the excavator break the clumps and improve the separation performance between the soil and the excavator. It can also push the garlic and soil after digging to the channel between two shovels, so as to prevent the garlic and soil to accumulate in front of the shovel and affect the process. The excavator has a chute to facilitate the adjustment of the digging depth of the excavator, and the angle of the blade is designed to be 20° [17L. Jinchuan, Z. Yimin, S. Xin, M. Song, and S. Xinpeng, "Optimization of the angle of artichoke harvester’s second-order flat shovel based on mathematica", Ganhan Diqu Nongye Yanjiu, vol. 35, no. 2, pp. 282-288.], which can greatly reduce the stress concentration of the excavator and improve the self-cleaning ability of the excavator. The excavators are designed with isolation tools on both sides of the shovel to create gaps between the garlic and the replanting crops, which can prevent the excavation shovel from bringing large soil lumps to other crops.

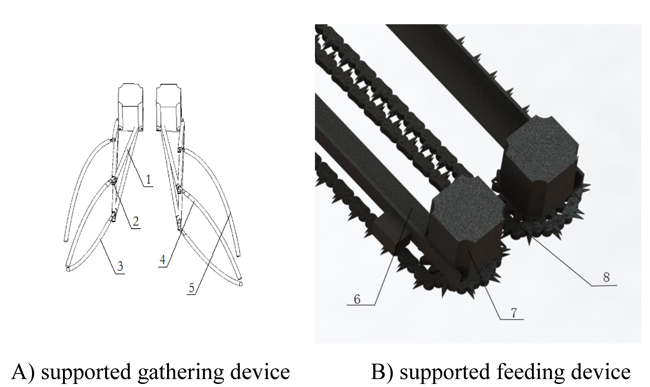

The garlic handling mechanism as shown in Fig. (3 ) is an important part of the harvester, and it is represented in a supported gathering device and a supported feeding device. The supported gathering device consists of a gathering tool and a support tool. The gathering tool has an upper part and a lower part, symmetrically designed with a separation angle of 23°. The gathering tool and the support tool are connected with an adjusting bolt that can modify the angle of the support tool according to the need of use. The garlic support tool is composed of gathering rods, supporting rods, and handling rods. The gathering rod is at the lowest position and the effect is to bring together the garlic excavated out of the shovel. The supporting rod is at the middle position with the highest strength, so as to withstand the external force to maintain the component shape. At the highest position is the handling rod, used to prevent garlic from falling down after excavation. By these means, garlic remains standing up with the support from various parts, until successfully collected by the clamps of the convey system [18L. Jianjun, S. Jiannong, and W. Jicheng, "Kinematic mechanical analysis of vibration separation device for garlic harvester", Hunan Nongye Daxue Xuebao, vol. 32, no. 5, pp. 536-539.].

) is an important part of the harvester, and it is represented in a supported gathering device and a supported feeding device. The supported gathering device consists of a gathering tool and a support tool. The gathering tool has an upper part and a lower part, symmetrically designed with a separation angle of 23°. The gathering tool and the support tool are connected with an adjusting bolt that can modify the angle of the support tool according to the need of use. The garlic support tool is composed of gathering rods, supporting rods, and handling rods. The gathering rod is at the lowest position and the effect is to bring together the garlic excavated out of the shovel. The supporting rod is at the middle position with the highest strength, so as to withstand the external force to maintain the component shape. At the highest position is the handling rod, used to prevent garlic from falling down after excavation. By these means, garlic remains standing up with the support from various parts, until successfully collected by the clamps of the convey system [18L. Jianjun, S. Jiannong, and W. Jicheng, "Kinematic mechanical analysis of vibration separation device for garlic harvester", Hunan Nongye Daxue Xuebao, vol. 32, no. 5, pp. 536-539.].

The handling mechanism is the key to the garlic harvester, and good realization of the supporting function is the basis for the successful realization of the garlic harvester's overall ability. Therefore, the working parameters are very important. Through calculation and simulation, the speed of the supported feeding device must be in some specific relationship with the spatial garlic growth parameters and the harvester speed, so as to achieve the optimal harvest efficiency. The optimal relationship is shown in the Table (1).

|

Fig. (3) Garlic handling mechanisms. |

The garlic harvester utilizes the holding conveyor mechanism to transfer the garlic to the next processing mechanism after they are digged out of the soil. The conveyor mechanism is installed with a 42° slop, the front end is lower and located above the excavation shovel. The rear end is located above the collection bucket, composed of two rows of 08BF1 chains, drive motor, sprocket and bracket. Two conveyor chains are arranged close to the side teeth in a staggered manner, to ensure smooth and firm clamping during the transport process. In addition, a tensioning mechanism is attached to the non-abutting side of the conveyor chain in order to further avoid gripping loss of the conveyor chain.

The line speed of the transport chain is limited by the speed of the garlic harvester, which also constrains some other important parameters such as the frequency of the soil beater, the speed of the cutting blade, and the size of the chain wheel etc. Therefore, a reasonable line speed is the key to coordinate and stabilize functionaries of the garlic harvester. The following parameters of the transport chain are calculated:

2.2.1. Transport Chain Line Speed Calculation

In theory, the garlic harvester runs at an average speed. While the support feeding bracket maintains its best speed, the feeding bracket rotates one cycle for a period of time t, and the number of garlic grabbed by the transport chain is n. Then t = 2.1s and n=10. The time interval for the conveyor chain to capture two neighboring garlic is

|

(1) |

In order to ensure the good operation of the straw limit cutting mechanism and good cutting effect, the distance between the neighboring garlic in the transport chain should be greater than 11cm. In order to ensure the quality of the harvest, 13cm has been adopted. Thus the transport chain ideal line speed is

|

(2) |

2.2.2. Transport Chain Load Calculation

During the course of the work, on the transport chain there are seven complete garlic on average, wrapped in earth, and three garlic stalks, which give a total mass of:

|

(3) |

The angle between the transport chain and the horizontal direction is α=42°, thus the resistance produced by m is

|

(4) |

By measuring the tension, kinematic viscosity, friction and other parameters of the chain, with 0.62m/s speed the estimated run-time resistance is Fres=6.7N.

Therefore, the load of the transport chain is

|

(5) |

2.2.3. Selection of Drive Motor and Determination of Sprocket Wheel Diameter

According to the transport chain speed and load, as well as stability, economic and other aspects of comprehensive factors, the final choice is a type-86 stepper motor [19"F. chaoyi, and F. Wei, “Selection and calculation of stepping motor", Machine Tool & Hydraulics, vol. 36, no. 5, pp. 310-313.].

The width of the stepper motor is 86mm, limiting the minimum diameter of the sprocket wheel to be Dwheel ≥ 86mm.

Let nm represents the drive motor speed, according to the relationship between the speed of the conveyor chain and the speed of the drive motor, the relationship between the sprocket wheel diameter and motor speed can be obtained as below

|

(6) |

According to the relationship between the transport chain load and the motor torque, the relationship between the sprocket diameter and the motor speed can be obtained:

|

(7) |

According to the above relations and the working characteristics of the stepper motor, considering the transport effect of the garlic harvester conveyor chain, the working stability and working efficiency of the motor, the optimal sprocket wheel diameter Dwheel is 120mm, and the motor driving speed nm is 99 rpm.

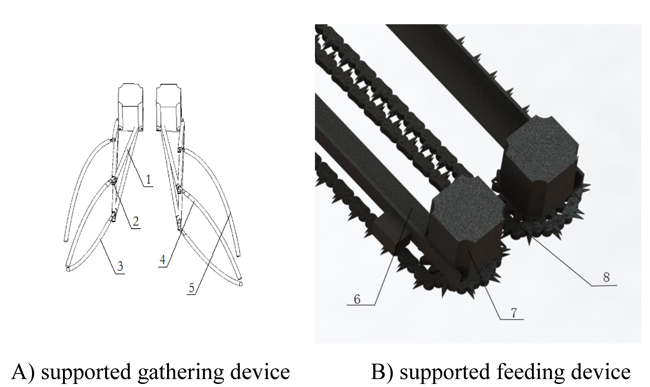

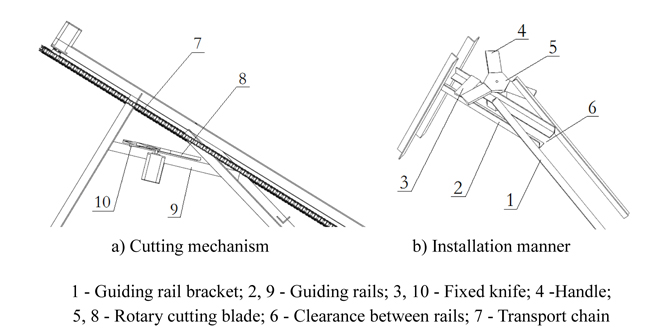

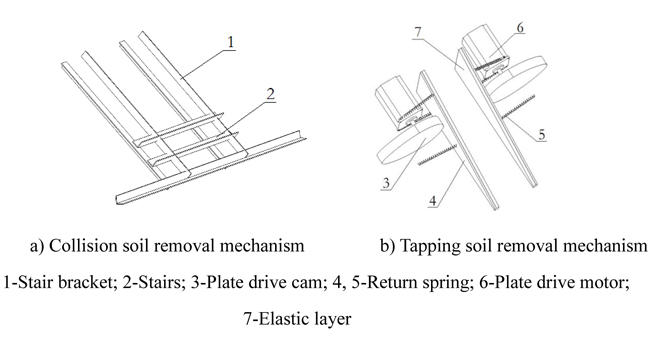

The soil removal device is shown in Fig. (4 ), which is divided into collision soil removal and tapping soil removal structures. The collision soil removal mechanism has stairs 2, which are divided into three levels from low, medium to high and gradually approach the transport chain, to achieve gradual removal of soil blocks on the garlic roots. On the top of the stair is an elastic layer which protects garlic from damages.

), which is divided into collision soil removal and tapping soil removal structures. The collision soil removal mechanism has stairs 2, which are divided into three levels from low, medium to high and gradually approach the transport chain, to achieve gradual removal of soil blocks on the garlic roots. On the top of the stair is an elastic layer which protects garlic from damages.

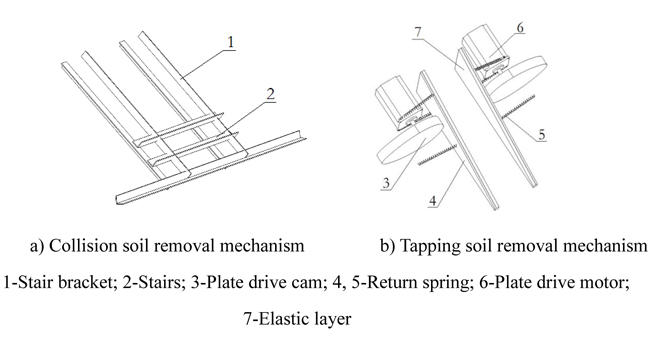

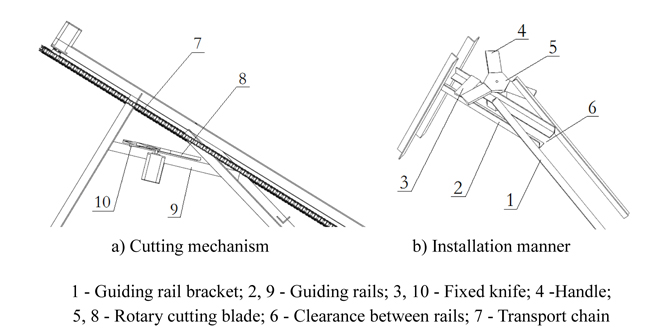

The limit cutting device is shown in Fig. (5 ). It mainly implements rapid positioning and cutting of garlic stalks, and according to the functionalities it can be divided into two parts the position guiding and cutting mechanisms. In front of the straw cutting machine, the position guiding rails are installed to position garlic, which can help avoid cutting damage to the garlic due to un-equal plant height. The position guiding rails consist of two parallel rails, with a 12mm gap between the rails that allows the straw to pass, but the garlic cannot pass. Under the combined effect of the transport chain and the position guiding rails, the straws remain sliding on the guiding rails for a certain distance, and the rotating cutting blade operates on the garlic and straw at a certain height, to ensure that the length of the remaining straw is the same. The contact surface between the guiding rail and the garlic is a curved surface with an elastic layer to prevent damages. The height of the rotating cutting blade can be adjusted to ensure the same length of the straw remained on the garlic.

). It mainly implements rapid positioning and cutting of garlic stalks, and according to the functionalities it can be divided into two parts the position guiding and cutting mechanisms. In front of the straw cutting machine, the position guiding rails are installed to position garlic, which can help avoid cutting damage to the garlic due to un-equal plant height. The position guiding rails consist of two parallel rails, with a 12mm gap between the rails that allows the straw to pass, but the garlic cannot pass. Under the combined effect of the transport chain and the position guiding rails, the straws remain sliding on the guiding rails for a certain distance, and the rotating cutting blade operates on the garlic and straw at a certain height, to ensure that the length of the remaining straw is the same. The contact surface between the guiding rail and the garlic is a curved surface with an elastic layer to prevent damages. The height of the rotating cutting blade can be adjusted to ensure the same length of the straw remained on the garlic.

|

Fig. (4) Soil removal devices. |

|

Fig. (5) Transport chain and limit cutting device. |

Garlic is continuously transported to the limit cutting mechanism through the guiding rail, and the straw is cut off by the rotating blade. The relative design calculation of the positioned straw cutting blade is as follows.

The average speed of the transport chain is Vchain=0.62m/s, the angle between the transport chain and the horizontal direction is α=42°, and the position guiding rail and the horizontal angle β = 21°. Thus, the running speed of garlic on the position guiding rail can be calculated as below.

|

(8) |

|

(9) |

According to the survey, 98% of the garlic height h exceeds 43cm. During processing, the transport chain holds the garlic at a point 13cm below the top and remains unchanged until transferred to the limit cutting mechanism. After reaching the limit cutting mechanism, the position guiding rails restricts the movement of the garlic, which may cause the garlic to fall off from the transport chain and lead to missing cut. If the garlic does not fall off, the following conditions should be satisfied.

|

(10) |

Among the above,Vchain=0.62m/s, Vg=0.58m/s, α=42°, β=21°, h=0.43m. Time t1 means starting from the garlic enters the transport chain, if the straw is not cut off, the time that the garlic falls off from the transport chain. Then below can be obtained.

|

(11) |

The cutting point of the straw limit cutting mechanism depends on the fixed knife 3, so the distance X from the horizontal knife installation point to the starting point should be less than or equal to 84cm. The 45cm in the design fully satisfies the requirements.

In addition, the time also limits the minimum speed of the rotary cutting tool. Within time t1, the garlic straw should be cut off. The rotating cutting tool has three handles 4, and under an ideal state of rotation, it can cut three garlic straws in one turn. Thus within the required time t1, the tool should rotate at least 1/3 cycle, namely

|

(12) |

The minimum speed of the rotary cutting tool is also limited by the missing rate of the garlic straw cutting process since a speed too low would cause high missing rate and affect the harvesting effect. In order to ensure that the missing rate is within the allowable range of garlic harvest, the speed of the rotary cutting tool should also meet the conditions as discussed below.

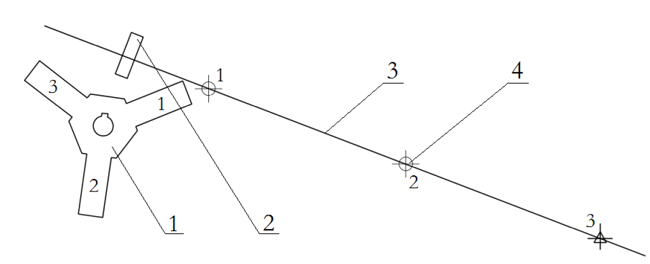

On the position guiding rails, the distance between the neighboring garlic is dg=12cm, and the forward speed is Vg=0.58m/s. As shown in Fig. (6 ), the extreme situation is that, soon after the No.1 blade rotates and passes the centerline 3, the No.1 garlic passes the same position. Theoretically, as long it can be ensured that the No. 2 blade reaches the same position before the No. 2 garlic, the garlic cutting blade will not exhibit miss-cutting phenomenon.

), the extreme situation is that, soon after the No.1 blade rotates and passes the centerline 3, the No.1 garlic passes the same position. Theoretically, as long it can be ensured that the No. 2 blade reaches the same position before the No. 2 garlic, the garlic cutting blade will not exhibit miss-cutting phenomenon.

|

Fig. (6) Working principle of the straw positioned cutting tool. |

|

(13) |

|

(14) |

Combined with the straw length requirements nknife ≥ 14rpm, the rotary speed of the straw limit cutting mechanism is nknife ≥ 115rpm. In addition, according to the characteristics of the stepper motor and the shear force required to cut the garlic straw, it can be seen that type 86 stepper motor satisfies the requirements and the best speed is between 115rpm and 215rpm.

2.3. The Control System Design

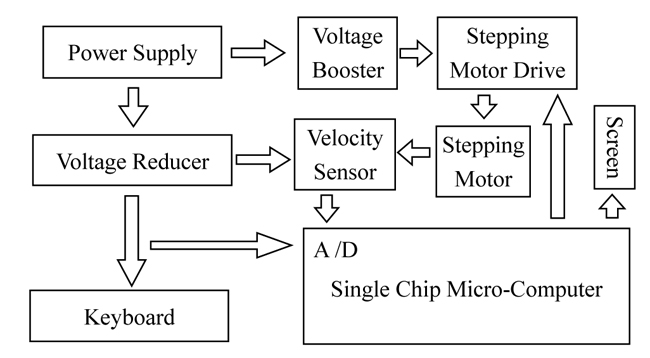

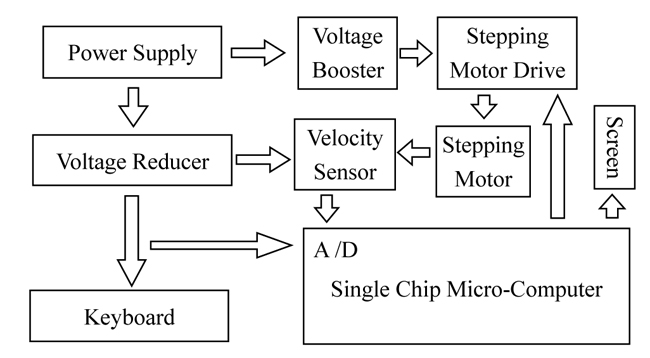

In order to facilitate the adjustment of the operating parameters of the garlic harvester, some mechanisms use the relevant electrical control system. In the specific design, the mechanisms that need continuous parameter adjustment and the mechanical structures too complex to adjust manually are replaced by the electrical control system with a STC89C52 microcontroller as the core processor. With power management, stepper motor control, data acquisition, human-computer interaction and other modules, the garlic harvester has achieved collection of operating status data, real-time display, key adjustment and other functions. The structure of the garlic harvester control system is shown in Fig. (7 ).

).

|

Fig. (7) Garlic harvester control system structure diagram. |

|

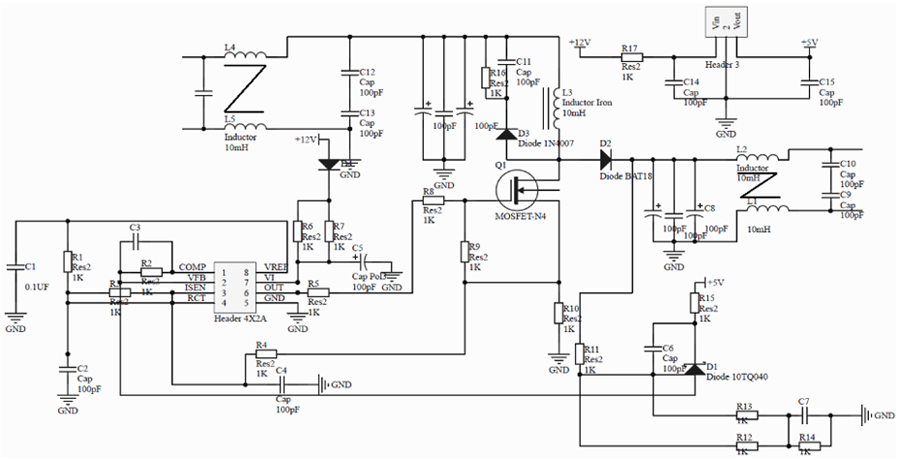

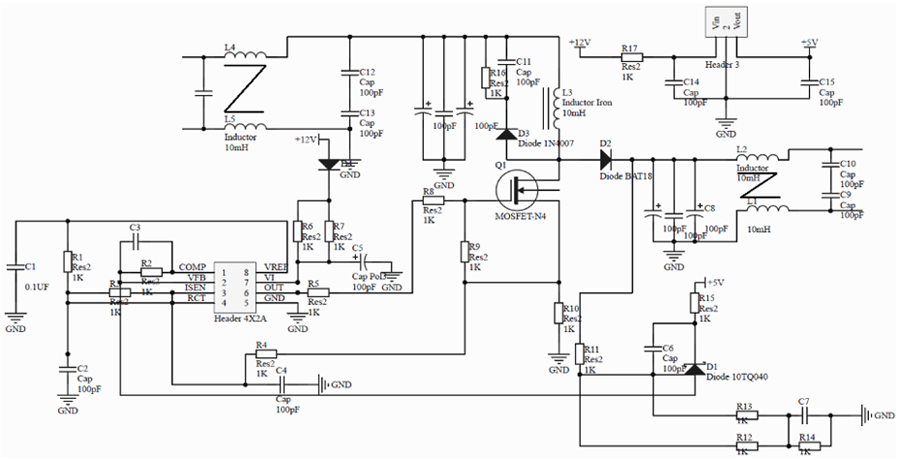

Fig. (8) Voltage enhancement circuit. |

The power of the control system is taken from the tractor generator and the vehicle battery of the garlic harvester. To meet the power supply demand of the stepper motor DC 60 ~ 110V, and 5V for the microcontroller and sensor, a suitable voltage lifting and reduction program must be designed. The existing technique to reduce the battery voltage from 24V to 5V is already mature and therefore utilized directly. For voltage lifting, the 24V battery should be boosted to 75V to meet the requirements. Since the voltage needs to be boosted more than 3 times, and stable operation of each stepper motor requires 245W power, the boost circuit cannot be designed as an isolated booster circuit to maintain the heavy load [20M. Jingkui, and L. Xiaohui, "Boost circuit design and simulation of lithium batteries in parallel", Research and Exploration of Laboratory, vol. 31, no. 9, pp. 214-218.]. Instead, it is similar to the working principle of the flyback switching power supply. After several improvements, it has been proven that the enhanced boost circuit as shown in Fig. (8 ) satisfies the requirements.

) satisfies the requirements.

This boost circuit does not exceed five times of the power supply voltage, and it can provide stable work when the input and output current is no more than 19A, with conversion efficiency between 93% and 97%. The boost multiplier formula [21Z. Linxian, L. Gang, and D. Binwei, "Design of DC electronic load based on boost circuit", Journal of Hubei Polytechnic University, vol. 29, no. 1, pp. 5-8.] is:

|

(15) |

where out Uout is the output voltage, Uin is the input voltage, and D is the duty cycle.

The power supply for the system is Uin=24V, and the stepper motor required operating voltage is Uout=80V, thus the duty cycle can be obtained as D ≈ 0.72.

In addition, this circuit allows 10V~60V DC voltage input, and the maximum stable operating current in the range of 10V~30V is Iin=30A. The output voltage is DC 12V~90V and the maximum stable operating current is Iout=19A. The rated current of the selected stepper motor of the garlic harvester is IN = 4.5A. Therefore, in order to ensure normal operation of the system, the power boost system should meet the following relationship:

|

(16) |

|

(17) |

That is, each booster board can drive a stepper motor. Then drive three stepper motors with three drive boards can be calculated as below:

|

(18) |

|

(19) |

|

(20) |

The operating current is within the allowable range of the power supply.

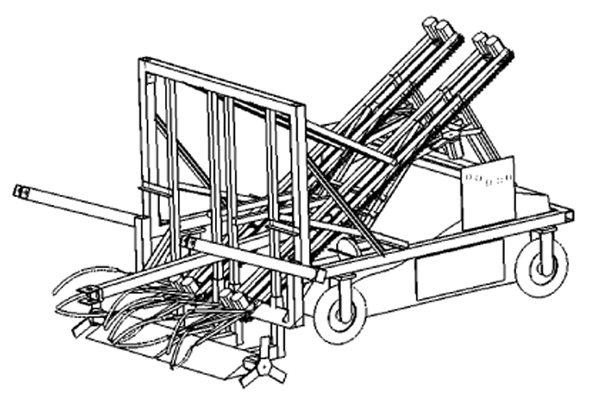

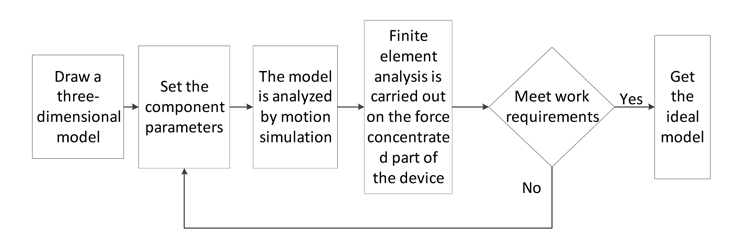

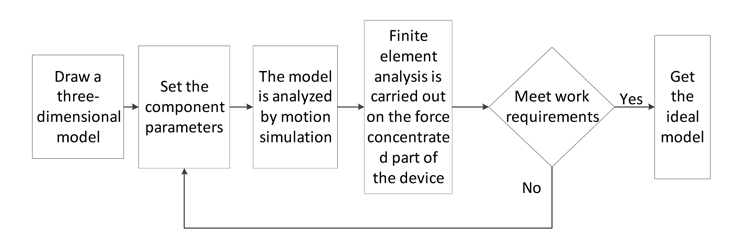

The mechanical structure design corresponding to each function of the garlic harvester model has been set up and simulated within the three-dimensional software. The modules of the model were assembled to form a garlic harvester machine model, as shown in Fig. (9 ).

).

|

Fig. (9) Three-dimensional model of the machine. |

The machine working speed, the transport chain line speed, rotational speed of the straw cutting knife have gone through simulation and debugging, as shown in Fig. (10 ), to ensure coordinated and stable machine operation and to achieve the highest efficiency and the best results. The final garlic harvester machine runs in good condition, and the simulation results showed that the garlic harvester meets the design requirements.

), to ensure coordinated and stable machine operation and to achieve the highest efficiency and the best results. The final garlic harvester machine runs in good condition, and the simulation results showed that the garlic harvester meets the design requirements.

|

Fig. (10) Flow chart of simulation. |

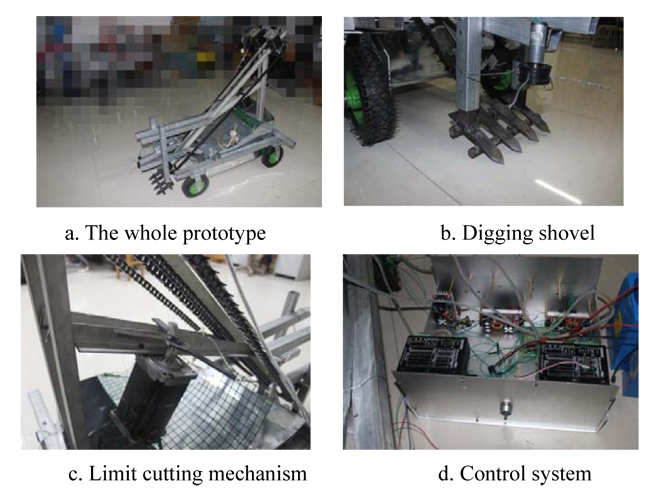

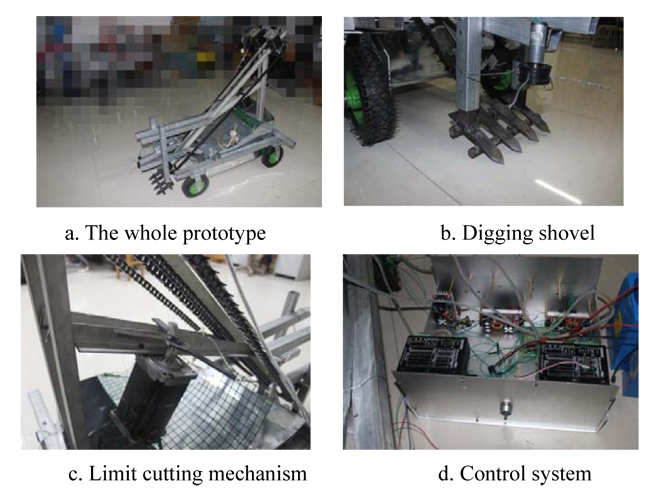

After determination of the detailed design with successful modeling and simulation, the parts and assembly drawings were exported for manufacturing, installation and adjustment. Eventually, the handling and gathering mechanism, clamping transport mechanism, limited cutting mechanism, separation sieve, collection bucket and other structures have all passed operating status and functionality tests. The design fulfills the conditions for mechanized garlic harvest conditions, and it is demonstrated in Fig. (11 ).

).

|

Fig. (11) Photographs of the real prototype. |

3.1. Simulation Experiment

A plot of ground that has soil quality similar to the garlic field has been chosen for simulation experiment. During the experiment the following should be ensured [22L. Deran, W. Xunjin, W. Yusheng, W. Yanyao, and Y. Ranbing, "Experiment and analysis on optimizing parameters of 4s-6 type garlic harvester", Journal of Qingdao Agricultural University, vol. 27, no. 1, pp. 81-83.].

- Select the appropriate material to make garlic models.

- According to the soil condition, choose a piece of experimental ground that has the same soil characteristics as the garlic planting field.

- Plant the garlic models in the field to ensure that its depth, plant spacing, row spacing parameters etc are the same as those real garlic grown conditions.

- Watering the test field and adjust the soil moisture to ensure that the humidity is the same as that of the garlic grown field. If necessary, carry out loosing or ramming work to ensure that the soil has the same hardness as the garlic grown field. Finally, overlay film to simulate the actual garlic environment.

The experimental process is as follows. First, drive the tractor to the empty land where the garlic models are not planted, and adjust the depth of the excavation shovel. Meantime, label each location hole on the excavating handle for corresponding depth to make it convenient for later use. Use the bottom hole to position the excavation shovel, drive the tractor forward to carry out excavation, measure and record the depth of excavation when running is stable. Move the positioning holes upwards until labeling all position holes is completed. The data are shown in Table (2).

Second, measure the tractor speed when the gear is set to the 1st and 2nd, configure the digging shovel excavation depth to be 100mm, run the tractor in the open space with the 1st and 2nd gear, control the throttle in the usual range. During running record time and distance when the operation is stable, perform calculation which gives the average speed of the tractor is 0.34m/s with the first gear, and 0.44m/s with the second gear.

Third, adjust parameters of the experimental gripping device. After determination of the excavation shovel depth and working speed, the experiments were continued in the experimental field where the garlic models have been buried. Use the second gear to drive the tractor and perform digging experiments, observe the status of the holding frame, record data and carry out analysis. The collapsing rate of garlic plants, the correction rate of collapsed garlic plants, the feeding rate of the feeding device and the gripping rate of the transport chain have been recorded against different support bracket angle and the rotational speed of the feeding device. Data from multiple tests have been organized as shown in Table (3).

Fourth, experiments on the correctness of the transport chain line speed calculation and the cutting knife speed. The operating conditions of the transport chain determine the success of garlic soil removal and straw cutting. Determine the appropriate speed to achieve the best harvest results, meantime the machine runs with more stability. Based on the calculated results of the design theory, the linear velocity of the conveyor chain and the speed of the cutting tool are adjusted synchronously up and down to observe whether there is garlic accumulation between the transport chain and the excavation shovel. The cutting rates are shown in Table (4).

Through the simulation test, the working parameters of the machine have been adjusted to the optimal state, and the prototype theoretically meets the requirements of garlic harvest.

3.2. Field Harvesting Experiment

In the field experiment, firstly use the optimal parameters determined from the simulation tests, observe the working status and harvesting effects of each mechanism. The relevant working parameters of garlic harvester were adjusted according to the harvesting effect, and finally, the optimal harvesting effect was obtained. After adjusting to the best condition, perform statistics of the excavation shovel missing rate, garlic damage rate, soil adhering rate, repeated cutting rate, miss cutting rate, and the production efficiency of the whole machine [23M. Veerangouda, S. Sushilendra, K.V. Prakash, and M. Anantachar, "Performance evaluation of tractor operated combine harvester", Karnataka Journal of Agricultural Sciences, vol. 23, no. 2, pp. 282-285.]. Table (5) shows field test results and the operation is presented in Fig. (12 ).

).

|

Fig. (12) Experiment in actual plant field. |

The results of the actual harvest tests showed that when the tractor is running with the first gear, the miss digging rate, miss cutting rate and garlic damage rate are relatively low, which are 0.96%, 1.41% and 0.43% respectively. The harvesting efficiency is considerably high, which is 0.06km2/h. When running with the second gear, the rates are 1.23%, 3.13% and 0.68%, respectively. The harvesting efficiency is higher than that of the same type of harvester. Experiments showed that the harvester has high efficiency, which can effectively reduce the harvest costs, improve harvest efficiency, and is suitable for wide promotion.

CONCLUSION

(1) Through analysis of the harvesting characteristics of the replant crops, a garlic harvester suitable to separate the garlic from the replant crops has been designed. A separation mechanism and a positioned cutting mechanism have been designed to separate garlic and keep the length of the straw remaining the same. From theoretical analysis and modeling analysis, optimal component parameters have been designed.

(2) Field experiments showed that the damage rate was 0.43%, the missing digging rate was 0.96%, and the miss cutting rate was 1.41% when the harvester working in the first gear harvest speed.When working in the second gear, the harvesting speed was faster but the harvesting effect was poor. Therefore, the harvester works best when working in the first gear.

(3) By further improving the digging shovel device, harvesting results can be better, harvesting efficiency can be higher. In addition, the harvester is small in size and suitable for single-row garlic harvesting and needs to rely on the tractor to drive. It can be considered to make the harvester work autonomously without using a tractor, which is easier to operate.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support of the Agricultural machinery and equipment innovation research and development projects of Shandong Province-garlic production throughout the mechanized technology R & D innovation (2017YF001), the National Modern Agricultural Industry Technical System-Specialized Vegetable Production Mechanization Construction Special (CARS-24-D-01) and Modern Agriculture Industry Technology System in Shandong Province (SDAIT-05-11).

REFERENCES

| [1] | M. Emerald, and P.S. Bisen, "Nutritional and therapeutic potential of garlic and onion (Allium sp.)", Current Nutrition and Food Science, vol. 12, no. 3, pp. 190-199. [http://dx.doi.org/10.2174/1573401312666160608121954] |

| [2] | Y. S. de Queiroz, P. B. Antunes, S. J. V. Vicente, G. R. Sampaio, J. Shibao, D. H. M. Bastos, and E. A. F. da S. Torres, "Bioactive compounds, in vitro antioxidant capacity and Maillard reaction products of raw boiled and fried garlic", Int. J. Food Sci. Technol., vol. 49, no. 5, pp. 1308-1314. |

| [3] | F. Haitao, "Analysis of the status quo of pay Haitao harvest mechanization in Jinxiang county garlic", Ara of Agricultural Machinery, vol. 8, p. 8. |

| [4] | F. Bayat, S. Rezvani, and A.E. Nosrati, "Effect of harvesting time and curing temperature on some properties of Iranian white garlic", Acta Hortic., vol. 877, no. 877, pp. 89-875. |

| [5] | G. Qinghai, and C. Sigang, "Research and development of front type garlic harvester", Hebei Agricultural Machinery, vol. 12, pp. 13-15. |

| [6] | Z. Zhongyu, and W. Jing, "Yanmar HZ20 self-propelled garlic harvester technology and benefit analysis", Agricultural Equipment Technology, vol. 42, no. 2, pp. 36-37. |

| [7] | X. Wenyi, Z. Hua, Z. Zhiqi, Z. Jin, and C. Zhongkai, "Design and experiment of small garlic combine", Journal of Agricultural Mechanization Research, vol. 26, no. 2, pp. 1-2. |

| [8] | Y. Xiangtao, H. Zhichao, H. Lianglong, and P. Baoliang, "Test and analysis of operational performance of 4DLB-2 type garlic combine harvester", Zhongguo Nongye Daxue Xuebao, vol. 18, no. 4, pp. 183-187. |

| [9] | W. Xiaoyu, C. Rongjiang, F. Qianqun, F. Qianqun, and C. Zhongkai, "Experimental study on garlic dislocation of wide narrow row planting method of", Agricultural Equipment and Vehicle Engineering, vol. 53, no. 8, pp. 5-8. |

| [10] | W. Linchong, "Design optimization of garlic harvester", Agricultural Development and Equipment, vol. 2, pp. 19-22. |

| [11] | X. Liran, L. Ruxin, W. Tiexin, and Z. Ji, "Design and simulation of split garlic harvester", Proceedings of the Chinese Society of Agriculture, vol. 43, no. s1, pp. 137-140. |

| [12] | F. Zhiqiang, M. Meng, Z. Guoying, and Z. Fu, "Design of garlic harvester based on Inventor", Agricultural Machinery, no. s2, pp. 109-110. |

| [13] | L. Deran, W. Xunjin, W. Yusheng, W. Yanyao, and Y. Ranbing, "Test and analysis of performance parameters of 4S-6 garlic harvester", Journal of Qingdao Agricultural University, vol. 27, no. 1, pp. 81-83. |

| [14] | F.M. Barrett, "Further work on the development of a simple tractor-mounted yam harvester", Arxiv Cornell University Library, vol. 1068, no. 1, pp. 103-114. |

| [15] | A.C. Rathinakumari, and D.M. Jesudas, "Design and development of tractor operated onion set planter", Indian Journal of Agricultural Sciences, vol. 85, no. 8, pp. 1038-1041. |

| [16] | H.M. Akhir, D. Ahmad, I.H. Rukunudin, S. Shamsuddin, and A. Yahya, "Design and development a sweet potato digging device", Pertanika J. Sci. Technol., vol. 22, no. 1, pp. 43-53. |

| [17] | L. Jinchuan, Z. Yimin, S. Xin, M. Song, and S. Xinpeng, "Optimization of the angle of artichoke harvester’s second-order flat shovel based on mathematica", Ganhan Diqu Nongye Yanjiu, vol. 35, no. 2, pp. 282-288. |

| [18] | L. Jianjun, S. Jiannong, and W. Jicheng, "Kinematic mechanical analysis of vibration separation device for garlic harvester", Hunan Nongye Daxue Xuebao, vol. 32, no. 5, pp. 536-539. |

| [19] | "F. chaoyi, and F. Wei, “Selection and calculation of stepping motor", Machine Tool & Hydraulics, vol. 36, no. 5, pp. 310-313. |

| [20] | M. Jingkui, and L. Xiaohui, "Boost circuit design and simulation of lithium batteries in parallel", Research and Exploration of Laboratory, vol. 31, no. 9, pp. 214-218. |

| [21] | Z. Linxian, L. Gang, and D. Binwei, "Design of DC electronic load based on boost circuit", Journal of Hubei Polytechnic University, vol. 29, no. 1, pp. 5-8. |

| [22] | L. Deran, W. Xunjin, W. Yusheng, W. Yanyao, and Y. Ranbing, "Experiment and analysis on optimizing parameters of 4s-6 type garlic harvester", Journal of Qingdao Agricultural University, vol. 27, no. 1, pp. 81-83. |

| [23] | M. Veerangouda, S. Sushilendra, K.V. Prakash, and M. Anantachar, "Performance evaluation of tractor operated combine harvester", Karnataka Journal of Agricultural Sciences, vol. 23, no. 2, pp. 282-285. |