- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Open Materials Science Journal

(Discontinued)

ISSN: 1874-088X ― Volume 13, 2019

Nanocontact Printing of Aminosilane for Bio-Device Fabrications

Kai-Yuen Lam*, 1, Fon-Shan Huang2, L. W. Chen2

Abstract

Nanocontact printing using hydrogen silsesquioxane (HSQ) soft stamps is studied for nanobio device fabrications in this work. The stamps with designed linewidth 80-200 nm were fabricated by low-dose e-beam lithography on HSQ films. The contact printing technique by using aminosilane as the ink on O2 plasma treated HSQ/Si substrates was developed. The plasma treatment, stamping force and stamping time were manipulated, and afterwards the transferred patterns were examined by the utilization of atomic force microscope and scanning electron microscope. Experimental results demonstrate that the nano-features on the HSQ stamps can be successfully transferred onto the substrates and passed a 3M tape peeling test under specific conditions in the range of 100-200 W O2 plasma treatment for 30 s. Nanolines with printed linewidth 97-205 nm were obtained. The nanopatterning of an antibody affinipure goat anti-mouse IgG(H+L) was also demonstrated onto the transferred aminosilane pattern surfaces for bio-device fabrication.

Article Information

Identifiers and Pagination:

Year: 2016Volume: 10

Issue: Suppl-1, M7

First Page: 70

Last Page: 78

Publisher Id: TOMSJ-10-70

DOI: 10.2174/1874088X01610010070

Article History:

Received Date: 14/4/2015Revision Received Date: 21/5/2015

Acceptance Date: 25/5/2015

Electronic publication date: 15/07/2016

Collection year: 2016

open-access license: This is an open access article licensed under the terms of the Creative Commons Attribution-Non-Commercial 4.0 International Public License (CC BY-NC 4.0) (https://creativecommons.org/licenses/by-nc/4.0/legalcode), which permits unrestricted, non-commercial use, distribution and reproduction in any medium, provided the work is properly cited.

* Address correspondence to this author at the Department of Electronic Engineering, I-Shou University, Kaohsiung, 840, Taiwan; Tel: 886-7-6577711; Ext: 6669; Fax: 886-7-6577056; E-mail: kylam@isu.edu.tw

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 14-4-2015 |

Original Manuscript | Nanocontact Printing of Aminosilane for Bio-Device Fabrications | |

INTRODUCTION

Microcontact printing is popularly used for the patterning of proteins and cells in biosensor technology, tissue engineering, and cell biology fundamental study. However, patterning the surface chemistry and topology at the molecular level is required to control both the adsorption of proteins and cells at well-defined locations on substrates for high sensitivity bio-devices fabrication [1Kane RS, Takayama S, Ostuni E, Ingber DE, Whitesides GM. Patterning proteins and cells using soft lithography. Biomaterials 1999; 20(23-24): 2363-76.

[http://dx.doi.org/10.1016/S0142-9612(99)00165-9] [PMID: 10614942] -3Liu WF, Chen CS. Engineering biomaterials to control cell function. Mater Today 2005; 8: 28-35.

[http://dx.doi.org/10.1016/S1369-7021(05)71222-0] ]. Nakamatsu et al. had fabricated a two-layered soft template: a film of polyethylene laminated on a poly(methyl methacrylate) (PMMA) sheet, and obtained a 35 nm HSQ transferred line pattern onto a Si surface at room temperature with 0.3 MPa press pressure [4Nakamatsu KT, Namatsu H, Matsui S. Room-temperature nanocontact printing using soft template. J Vac Sci Technol B 2006; 24: 195-9.

[http://dx.doi.org/10.1116/1.2151913] ]. Therefore, nanocontact printing of organosilanes can be utilized to generate nanoscale patterns at low temperature and pressure for the accurate placement of proteins and cells on silicon oxide substrates. We have developed a relatively simple process to fabricate HSQ soft stamps with hard upper-part protruding areas for nanoscale contact printing [5Dai MT, Lam KY, Chen HJ, Huang F-S. Nanocontact printing using a hydrogen silsesquioxane stamp with low e-beam dose. J Electrochem Soc 2007; 154(7): H636-41.

[http://dx.doi.org/10.1149/1.2737346] ]. The stamps with linewidth 40-190 nm were obtained by low-dose e-beam lithography on low-temperature prebaked HSQ films. The contact printing using these HSQ soft stamps with ink aminosilane was also demonstrated by a manual rotary machine under ambient condition in our previous studies, and line patterns with about 1000 μm in length were properly transferred onto HSQ/Si substrates at room temperature [5Dai MT, Lam KY, Chen HJ, Huang F-S. Nanocontact printing using a hydrogen silsesquioxane stamp with low e-beam dose. J Electrochem Soc 2007; 154(7): H636-41.

[http://dx.doi.org/10.1149/1.2737346] , 6Lam KY, Chen LW, Chen HJ, Huang F-S. The Study on Nano-contact Printing with Ink Aminosilane. In: 5th International Nanoimprint and

Nanoprint Technology Conference. 2006; pp. 184-5. ]. However, breaks and ragged lines were found in the patterns. The printing process must be refined and done by precise mechanic stamping machines in order to improve the quality of the prints for nanobio device fabrication.

Contact printing is composed of two main steps: inking and printing. The alkoxy groups of aminosilane can provide easy cross-linkage with the hydroxyl groups at silicon oxide surfaces [7Ulman A. An introduction to ultrathin organic films from Lan-gmuir-Blodgett to self-assembly. Cambridge: Academic Press 1991; pp. 237-8.

[http://dx.doi.org/10.1016/B978-0-08-092631-5.50010-5] ]. We found that a sufficient amount of aminosilane molecules was easily adsorbed onto the HSQ stamp within 20 s inking time [5Dai MT, Lam KY, Chen HJ, Huang F-S. Nanocontact printing using a hydrogen silsesquioxane stamp with low e-beam dose. J Electrochem Soc 2007; 154(7): H636-41.

[http://dx.doi.org/10.1149/1.2737346] ]. Therefore, a key issue is to make the ink molecules sticking far more to the substrate than to the HSQ stamp during printing. Lange et al. applied an anti-stick treatment on polydimethylsiloxane (PDMS) material to dramatically decrease the surface energy of their stamp [8Lange SA, Benes V, Kern DP, HAorber JK, Bernard A. Microcontact printing of DNA molecules. Anal Chem 2004; 76(6): 1641-7.

[http://dx.doi.org/10.1021/ac035127w] [PMID: 15018562] ]; and Galio et al. employed an adhesion promoter to enhance the interacting between ink molecules and their GaAs substrates [9Galio P, Viallet B, Daran E, Fontaine C. Efficient aminosilane adhesion promoter for soft nanoimprint on GaAs. Appl Phys Lett 2005; 87(18): 183111.

[http://dx.doi.org/10.1063/1.2123386] ]. But, a brief O2 plasma treatment on HSQ/Si substrates can easily increase the number of hydroxyl groups, and then provide a strong preferential absorption of ink aminosilane to the substrate surface. Since chemical reactions occur as a result of collisions between reacting molecules, the concentrations, contact abilities, and chemical natures of the hydroxyl groups and the ink molecules can be utilized to determine the heterogeneous reaction rate at the ink-substrate interface. If the interacting force between the ink molecules and the substrate surface is stronger than that occurring between the ink molecules and the stamp surface and the heterogeneous reaction at the ink-substrate interface produces enough chemical bonds within a short printing time, then the ink molecules can be transferred efficiently and quickly from the stamp surface onto HSQ/Si substrates without affecting the size of the patterns for quality printing.

In this work, HSQ soft stamps with nanoscale features are fabricated. Then, aminosilane is used as the ink for the HSQ stamps on O2 plasma treated HSQ/Si substrates. The O2 plasma treatment, stamping force and stamping time are manipulated to study the nanocontact printing and find the optimum conditions for the quality printing of different nano-feature sizes at low temperature and pressure. Afterwards, affinipure goat anti-mouse IgG(H+L) is utilized to demonstrate the chemisorption of protein onto the transferred pattern surfaces for bio-device applications. The stamp fabrication, printing process, protein patterning, and experimental results are presented in the following sections.

EXPERIMENTAL

HSQ soft stamps with hard upper-part protruding areas were obtained for nanocontact printing in our previous work, and the stamps were further improved and fabricated in this study [5Dai MT, Lam KY, Chen HJ, Huang F-S. Nanocontact printing using a hydrogen silsesquioxane stamp with low e-beam dose. J Electrochem Soc 2007; 154(7): H636-41.

[http://dx.doi.org/10.1149/1.2737346] ]. The HSQ (FOX-15, Dow Corning, Inc.) mixed with its solvent, methyl isobutyl ketone (MIBK), in a ratio of HSQ/MIBK=2:1 was used as the stamp material. This diluted HSQ was spin-coated onto a 6 in. silicon wafer and consequently baked on a hot-plate at 120°C for 3 min to evaporate the solvent. A mask which consists of different line widths, 80, 100, 150, and 200 nm, was designed with a line-width-to-space ratio of 1:10 for e-beam lithography on a Leica Weprint-200 stepper. The exposure was carried out with energy of 40 keV and a dose of 280 μC/cm2. In order to develop the HSQ patterns, exposed films were soaked in a TMAH solution with a concentration of 4-5% for 20 s. Finished HSQ stamps were then rinsed with deionized (DI) water to remove residue. The defined patterns of HSQ stamps were observed by the utilization of scanning electron microscopy (SEM).

In our nanocontact printing, aminosilane (Z-6020 Silane, Dow Corning, Inc.) mixed with a high purity ethanol (Sigma-Aldrich Co.) in a ratio of aminosilane/ethanol=0.01 cc:5cc was spin-coated onto a flat silicon dioxide ink pad. HSQ stamps with predefined patterns were pressed against the ink pad and then ready for printing. In the printing process performed on HSQ/Si substrates, diluted HSQ, HSQ/MIBK=4:5, was spin-coated onto a cleaned 6 in. silicon wafer and consequently baked on a hot-plate at 50°C for 3 min. Then a brief O2 plasma treatment of the HSQ/Si substrate was executed in a Branchy-D016 to obtain a preferential adhesion of ink on substrate. Afterwards, an anode bonder (Electronic Visions Co., EV501) was initialized for the printing process at room temperature. As shown in Table 1, O2 plasma treatment, stamping force, and stamping time were set as process parameters to study the contact printing and find the optimum conditions for the quality printing of different nano-feature sizes. The transferred patterns and their adhesive power towards the substrates were examined by utilizing atomic force microscope (AFM) and SEM and sticking a 3M tape onto the transferred patterns.

Immunoglobulin G (IgG) is the most abundant antibody in serum and tissue liquids, it can bind to many kinds of pathogens, and protects the body against them. An affinipure goat anti-mouse IgG(H+L) was utilized to demonstrate the chemisorption of protein onto the printed aminosilane lines for bio-device nanopatternings. Glutraic dialdehyde (GA) was used as a coupling agent due to its alcohol functional group (CHO) at both ends providing bonding with the antibody and the amino group in aminosilane [10Tamaoka E, Ueda T, Aoi N, Mayumi S. Suppressing oxidization of hydrogen silsesquioxane films by using H2O plasma in a shing process. IITC 1998. In: Proceeding IEEE. 1998; pp. 48-50.]. The printed lines on HSQ/Si substrates were first incubated in a 5% wt GA in phosphate-buffered saline (PBS) for 2 hours, washed with deionized water for 1 minute, and then incubated with a 0.15 mg/ml affinipure goat anti-mouse IgG(H+L) for another 4 hours. Finished samples were then washed with deionized water to remove residue. The defined patterns of the chemisorption were observed by the utilization of AFM.

RESULTS AND DISCUSSION

HSQ Stamp

From the SEM image of a 80 nm designed linewidth stamp fabricated with a process condition of 120°C prebake for 3 min, 280 μC/cm2 e-beam exposure, and 20 s development in a 5% TMAH solution, lines obtained are very straight and have a superior sidewall profile with an aspect ratio of 6.86, but the critical dimension of the fabricated linewidth is only 50 nm after development [5Dai MT, Lam KY, Chen HJ, Huang F-S. Nanocontact printing using a hydrogen silsesquioxane stamp with low e-beam dose. J Electrochem Soc 2007; 154(7): H636-41.

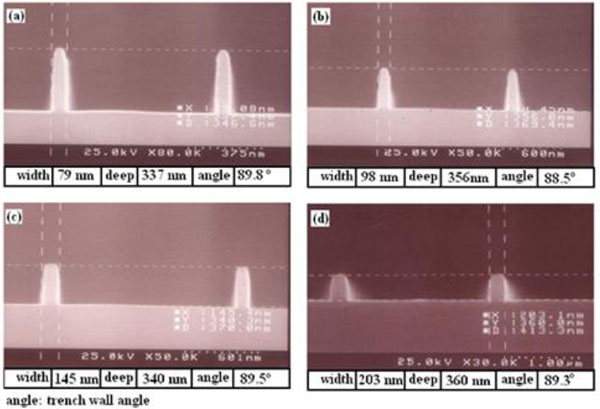

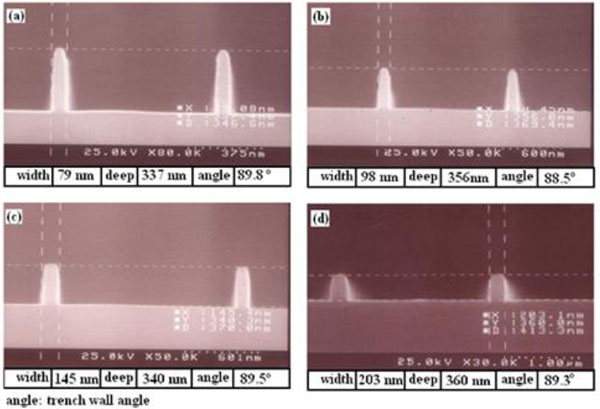

[http://dx.doi.org/10.1149/1.2737346] ]. A low-dose e-beam directly writes patterns on HSQ films to rearrange part of the cage structure in the upper portion of the films into a network structure. A moderate concentration development solution with a short development time is necessary to fabricate perfect vertical straight sidewall stamps. However, TMAH concentration determines the development time required for the HSQ stamps. An improper combination of TMAH concentration and development time can induce obvious lateral etching of the exposed areas, which seriously thins the linewidth of HSQ stamps. When the concentration of the TMAH solution was reduced to 4% in the aforementioned process condition, Fig. (1 ) shows the SEM images of different line size patterns fabricated on the HSQ stamp. It is observed that the lines in each pattern are straight and have a trench wall angle of 89°. The fabricated linewidths obtained for 80, 100, 150, and 200 nm designed line patterns are accurate: 79, 98, 145, and 203 nm, and they have an aspect ratio of 4.27, 3.63, 2.34, and 1.77, respectively. The HSQ stamp was used for our nanocontact printing.

) shows the SEM images of different line size patterns fabricated on the HSQ stamp. It is observed that the lines in each pattern are straight and have a trench wall angle of 89°. The fabricated linewidths obtained for 80, 100, 150, and 200 nm designed line patterns are accurate: 79, 98, 145, and 203 nm, and they have an aspect ratio of 4.27, 3.63, 2.34, and 1.77, respectively. The HSQ stamp was used for our nanocontact printing.

Nanocontact Printing on HSQ/Si Substrate

In the printing process, aminosilane molecules adsorbed onto the stamp surface were consequently transferred onto the O2 plasma treated substrates. It is observed from the AFM measurements that the transferred pattern was easily peeled off under the following circumstances: (i) weak O2 plasma treatment, (ii) low stamping force, or (iii) short stamping time [5Dai MT, Lam KY, Chen HJ, Huang F-S. Nanocontact printing using a hydrogen silsesquioxane stamp with low e-beam dose. J Electrochem Soc 2007; 154(7): H636-41.

[http://dx.doi.org/10.1149/1.2737346] ]. As shown in Fig. (2 ), linkage of the ink molecules to the substrate surface is through the reaction between the methoxy groups of the ink molecules and the hydroxyl groups at the HSQ surface:

), linkage of the ink molecules to the substrate surface is through the reaction between the methoxy groups of the ink molecules and the hydroxyl groups at the HSQ surface:

|

(1) |

|

Fig. (2) Linkage of ink molecules to the O2 plasma treated HSQ/Si substrate surface. |

The O2 plasma treatment of the HSQ/Si substrate breaks the Si-H bonds and creates the Si-OH and H-OH bonds in the HSQ film [11Feng J, Gao C, Wang B, Shen J. A novel process for inking the stamp with biomacromolecule solution used in reactive microcontact printing. Colloids Surf B Biointerfaces 2004; 36(3-4): 177-80.

[http://dx.doi.org/10.1016/j.colsurfb.2004.06.001] [PMID: 15276634] ]. Its intensity controls the density of hydroxyl groups generated at the substrate surface. The stamp might be considered as a type of sponge impregnated with ink. The stamping force determines the amount of ink transferred from the printing plate to the substrate surface. Since chemical reactions occur as a result of collisions between reacting molecules, reaction rate is directly proportional to the frequency of molecular collisions. Both the O2 plasma intensity and stamping force affect the heterogeneous reaction rate at the ink-substrate interface. In addition, time is needed for the reaction between the reacting molecules after their contact. Therefore, a proper manipulation of the O2 plasma intensity, stamping force and stamping time is important for the creation of enough chemical bonds at the interface to make the ink sticking well to the substrate surface.

Treating the HSQ/Si substrate with a high intensity of O2 plasma can make the ink molecules sticking far more to the substrate than to the HSQ stamp during printing. Fig. (3 ) shows the AFM images of aminosilane-printed line pattern on HSQ/Si substrates treated with 100W O2 plasma for 30 s. As shown in Fig. (3a

) shows the AFM images of aminosilane-printed line pattern on HSQ/Si substrates treated with 100W O2 plasma for 30 s. As shown in Fig. (3a ), the stamp pattern with 145 nm fabricated linewidth was successfully transferred onto the substrate under a condition of 30N stamping force for 2 min. The printed lines have their height and width of 2.8 and 156 nm, respectively, which is slightly wider than the feature size. When the stamp feature was reduced to 79 nm, it is observed from Fig. (3b

), the stamp pattern with 145 nm fabricated linewidth was successfully transferred onto the substrate under a condition of 30N stamping force for 2 min. The printed lines have their height and width of 2.8 and 156 nm, respectively, which is slightly wider than the feature size. When the stamp feature was reduced to 79 nm, it is observed from Fig. (3b ) that a successful printing of the stamp pattern onto the 30s, 100W O2 plasma treated substrate required the stamping force to be increased further up to 45N for 2 min. The printed pattern has an ideal wire shape, but its height and width: 4.8 and 195 nm are thick and much wider than the feature size on the stamp. In parallel with the way just mentioned, as shown in Table 2, the printing of the 79 nm line pattern was also executed on a HSQ/Si substrate treated with 200W O2 plasma for 30 s. The line feature on the stamp was successfully transferred onto the substrate under a condition of 25N stamping force for 2 min. The printed lines have their height and width reduced to 1.3 and 98 nm, respectively.

) that a successful printing of the stamp pattern onto the 30s, 100W O2 plasma treated substrate required the stamping force to be increased further up to 45N for 2 min. The printed pattern has an ideal wire shape, but its height and width: 4.8 and 195 nm are thick and much wider than the feature size on the stamp. In parallel with the way just mentioned, as shown in Table 2, the printing of the 79 nm line pattern was also executed on a HSQ/Si substrate treated with 200W O2 plasma for 30 s. The line feature on the stamp was successfully transferred onto the substrate under a condition of 25N stamping force for 2 min. The printed lines have their height and width reduced to 1.3 and 98 nm, respectively.

A high intensity of O2 plasma creates a high density of hydroxyl groups at the HSQ/Si substrate surface which can react with large number of aminosilane molecules. When the stamping force is increased to a specific quantity which is complementary to the plasma intensity for creating enough chemical bonds at the ink-substrate interface, the ink pattern can be properly transferred from the stamp surface onto the substrate. However, the reactants are able to meet only at the ink-substrate interface in the heterogeneous reaction. The area of the interface also determines the rate of reaction. Since the applied quantities of O2 plasma intensity and stamping force can be complementary to each other in the subjected requirement for a successful printing, nanocontact printing of stamps with smaller feature sizes requires an increase either in the stamping force or in the O2 plasma intensity. A strong O2 plasma intensity on the HSQ/Si substrate can provide a low stamping-force nanoscale contact printing with ink aminosilane. But, it seems the critical dimension of printed linewidths depends on the printing condition.

HSQ is a resinous inorganic polymer. It consists of siloxane-containing cages. During thermal curing of HSQ films, there are basically four possible stages: (i) room temperature up to 200°C: solvent loss, (ii) 250-350°C: cage-network redistribution, (iii) 350-450°C: Si-H dissociation and network redistribution, and (iv) >450°C: collapse of the pore structure, and the porosity of the cured HSQ films increases with the network/cage ratio [12Yang CC, Chen WC. The structures and properties of hydrogen silsesquioxane (HSQ) by thermal curing. Mater Chem 2002; 12: 1138-41.

[http://dx.doi.org/10.1039/b107697n] ]. Therefore, HSQ stamps might be considered as a type of sponge, and ethanol and aminosilane molecules are absorbed into the bulk part of the stamps by capillary attraction during inking. Delamarche et al. found that the resolution and accuracy attainable with the process of contact printing are constrained by the range and type of diffusive phenomena that occur on surfaces and air when the ink molecules are transferred to the substrate surfaces during stamping [13Delamarche K, Schmid H, Bietsch A, et al. Transport mechanisms of alkanethiols during microcontact printing on gold. J Phys Chem 1998; 102(18): 3324-34.

[http://dx.doi.org/10.1021/jp980556x] ]. The pathways for transport of an ink into nonprinted regions of a substrate, whether the ink is liquid or solid, involve its transport along the interface between stamp and substrate as well as a gas diffusion mechanism through the ambient. Thus, in our nanocontact printing, a high stamping force can worsen the dispersal of ink along the interface between stamp and substrate, and an increase in O2 plasma intensity enhances the sticking probability of ink onto the nonprinted surfaces.

Table 3 shows the printed linewidths measured from AFM images of stamps with 98 and 145 nm fabricated line features under different stamping forces for 2 min on high intensity O2 plasma treated substrates. As shown in Table 3, the 98 nm line pattern was successfully transferred onto the substrate treated with 100W O2 plasma intensity for 30 s when the stamping force was increased to 30N. The printed linewidth is 107 nm which is slightly wider than the feature size. However, it is observed that the printed linewidth increases with further increase on the stamping force: 107, 127, and 136 nm linewidths obtained for 30, 35, and 40N stamping forces, respectively. For the stamp with 145 nm line feature, Table 3 shows that a less stamping force: 25N for 2 min is required for the proper transfer of the line pattern onto the substrate treated with 200W O2 plasma intensity for 30 s. Similarly, the printed linewidth also increases with increasing stamping force: 166, 175, and 185 nm linewidths obtained for 25, 30, and 40N stamping forces, respectively.

In order to study the effect of O2 plasma intensity on printed linewidth, stamp with 145 nm fabricated line feature was printed onto substrates treated 30 s with different O2 plasma intensities. As shown in Table 4, a condition of 30N stamping force for 2 min is required for the successful transfer of the 145 nm line pattern onto the substrate treated with 100W O2 plasma intensity, and the printed linewidth is 156 nm which is only slightly wider than the feature size. It is observed that the printed linewidth increases with increasing plasma intensity: 175 nm linewidth obtained for 200W plasma intensity.

A key issue for the success of a nanocontact printing is to make the ink sticking well to the substrate surface during the printing process. Treating the HSQ/Si substrate with high intensities O2 plasma can provide a strong preferential absorption of ink aminosilane to the substrate surface. If the heterogeneous reaction creates enough chemical bonds at the ink-substrate interface, then the ink molecules can be transferred efficiently from the stamp surface onto the HSQ/Si substrate. However, a high stamping force induces obvious lateral spreading of ink, and a high intensity plasma treatment enhances the ink spreading. Therefore, a high intensity plasma treatment with a low stamping force and a short stamping time is the necessary condition for a quality nanoscale contact printing.

In the heterogeneous reaction, the reactants are able to meet only at the ink-substrate interface, so the area of the interface also affects the rate of reaction. The optimum conditions for the quality printing of different nano-feature sizes can be different. In order to find the optimum condition for the quality printing of each feature size on our HSQ stamp, O2 plasma intensity and stamping force were confined in the range of 100-200W for 30 s and 25-45N, respectively, and the stamping time was estimated between 1-2 min. AFM results showed that different size of fabricated line patterns on the HSQ stamp are able to properly be printed onto the HSQ/Si substrates under specific process conditions over the range we used, and nanolines with width 97-205 nm were obtained. The optimum process conditions for printing 98, 145, and 203 nm line patterns are shown in Table 5, and their printed linewidths obtained from AFM measurements are 107, 156, and 205 nm, respectively. Those critical dimensions are only slightly wider than the corresponding feature sizes.

The SEM image of aminosilane line pattern printed from the 98 nm fabricated line feature on HSQ/Si substrates with its optimum process condition: 100W O2 plasma treatment for 30 s and 30N stamping for 2 min is shown in Fig. (4 ). Wires in the pattern are straight and continuous, and their height and width are 3 and 101 nm, respectively. Thus, the 98 nm line features defined on the stamp are accurately transferred onto the HSQ/Si substrate. Since inks diffuse during the printing step, long stamping time can lead inks to spread obviously, resulting in a limit to the minimum feature size attainable. It seems a 2 min stamping time is perfect for our aminosilane/HSQ system.

). Wires in the pattern are straight and continuous, and their height and width are 3 and 101 nm, respectively. Thus, the 98 nm line features defined on the stamp are accurately transferred onto the HSQ/Si substrate. Since inks diffuse during the printing step, long stamping time can lead inks to spread obviously, resulting in a limit to the minimum feature size attainable. It seems a 2 min stamping time is perfect for our aminosilane/HSQ system.

|

Fig. (4) SEM image of aminosilane pattern printed from the 98 nm fabricated line feature with 100W O2 plasma treatment for 30 s and 30N stamping for 2 min. |

In addition, a 3M tape peeling test was used to examine the adhesive power of the 98 nm line transferred pattern towards the substrate. Comparing the patterns on their AFM images before and after the 3M tape was being stuck-and-removed, it shows that nothing is peeled off from the stamped pattern after the removal of the tape. The process condition provides enough chemical bonds to be created at the ink-surface interface. The transferred pattern of aminosilane has a strong adhesion towards the substrate.

Due to the free amino functional groups contained in aminosilane molecules, the printed lines can be used for the nanopatterning of different proteins and cells. Fig. (5a ) shows a 145 nm aminosilane printed line pattern for demonstrating the chemisorption of an antibody onto the printed line surfaces. It is obtained with a condition of 200W O2 plasma treatment for 30 s and 40N stamping for 2 min. The width and height of the lines are 3.9 and 195 nm, respectively. Fig. (5b

) shows a 145 nm aminosilane printed line pattern for demonstrating the chemisorption of an antibody onto the printed line surfaces. It is obtained with a condition of 200W O2 plasma treatment for 30 s and 40N stamping for 2 min. The width and height of the lines are 3.9 and 195 nm, respectively. Fig. (5b ) shows the AFM image of the line pattern after coating with the antibody affinipure goat anti-mouse IgG(H+L). The width and height of the antibody-coated lines are 8.6 and 333 nm, respectively. The width and height estimated from the images and their differences are shown in Table 6. It can be clearly seen that the antibody adheres preferentially to the aminosilane molecules. Since a coupling agent (GA) with alcohol functional group (CHO) at both ends was used to provide bonding with the antibody and the amino group in aminosilane, the increased width in the antibody-coated aminosilane lines is a probable effect caused by improper surface chemistry treatment on the aminosilane lines. Advanced surface modification methods could improve the quality of future protein absorptions.

) shows the AFM image of the line pattern after coating with the antibody affinipure goat anti-mouse IgG(H+L). The width and height of the antibody-coated lines are 8.6 and 333 nm, respectively. The width and height estimated from the images and their differences are shown in Table 6. It can be clearly seen that the antibody adheres preferentially to the aminosilane molecules. Since a coupling agent (GA) with alcohol functional group (CHO) at both ends was used to provide bonding with the antibody and the amino group in aminosilane, the increased width in the antibody-coated aminosilane lines is a probable effect caused by improper surface chemistry treatment on the aminosilane lines. Advanced surface modification methods could improve the quality of future protein absorptions.

CONCLUSION

In this work, aminosilane-based nanocontact printing using a HSQ soft stamp was studied for bio-device applications. The stamp with designed linewidth 80-200 nm was fabricated by low-dose e-beam lithography on a HSQ film according to the results obtained in our previous work. Aminosilane was used as the ink for the HSQ stamp on O2 plasma treated HSQ/Si substrates. Experiment results show that treating substrates with high intensity O2 plasma provides the ink molecules sticking far more to the substrate than to the HSQ stamp. A high intensity plasma treatment with a low stamping force and a short printing time is the necessary condition for a quality nanoscale contact printing. The nano-features on the HSQ stamp can be successfully transferred onto the substrates with strong adhesion under specific conditions in the range of 100-200W O2 plasma treatment for 30 s. Nanolines with printed linewidth 97-205 nm were obtained. Since aminosilane molecules contain free amino functional groups, the printed aminosilane lines were employed for the specific chemisorption of antibody affinipure goat anti-mouse IgG(H+L). We can apply this technology to the patterning of proteins and cells in bio-science study in the future.

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

In this work, authors would like to thank the Ministry of Science & Technology of Taiwan, through grant number NSC 93-2215-E-007.

REFERENCES

| [1] | Kane RS, Takayama S, Ostuni E, Ingber DE, Whitesides GM. Patterning proteins and cells using soft lithography. Biomaterials 1999; 20(23-24): 2363-76. [http://dx.doi.org/10.1016/S0142-9612(99)00165-9] [PMID: 10614942] |

| [2] | Lin SP, Chuang TL, Chen JJ, Tzeng SF. Design of microscopy-based microcontact printing stamp and alignment device for patterned neuronal growth. J Med Biol Eng 2004; 1: 45-50. |

| [3] | Liu WF, Chen CS. Engineering biomaterials to control cell function. Mater Today 2005; 8: 28-35. [http://dx.doi.org/10.1016/S1369-7021(05)71222-0] |

| [4] | Nakamatsu KT, Namatsu H, Matsui S. Room-temperature nanocontact printing using soft template. J Vac Sci Technol B 2006; 24: 195-9. [http://dx.doi.org/10.1116/1.2151913] |

| [5] | Dai MT, Lam KY, Chen HJ, Huang F-S. Nanocontact printing using a hydrogen silsesquioxane stamp with low e-beam dose. J Electrochem Soc 2007; 154(7): H636-41. [http://dx.doi.org/10.1149/1.2737346] |

| [6] | Lam KY, Chen LW, Chen HJ, Huang F-S. The Study on Nano-contact Printing with Ink Aminosilane. In: 5th International Nanoimprint and Nanoprint Technology Conference. 2006; pp. 184-5. |

| [7] | Ulman A. An introduction to ultrathin organic films from Lan-gmuir-Blodgett to self-assembly. Cambridge: Academic Press 1991; pp. 237-8. [http://dx.doi.org/10.1016/B978-0-08-092631-5.50010-5] |

| [8] | Lange SA, Benes V, Kern DP, HAorber JK, Bernard A. Microcontact printing of DNA molecules. Anal Chem 2004; 76(6): 1641-7. [http://dx.doi.org/10.1021/ac035127w] [PMID: 15018562] |

| [9] | Galio P, Viallet B, Daran E, Fontaine C. Efficient aminosilane adhesion promoter for soft nanoimprint on GaAs. Appl Phys Lett 2005; 87(18): 183111. [http://dx.doi.org/10.1063/1.2123386] |

| [10] | Tamaoka E, Ueda T, Aoi N, Mayumi S. Suppressing oxidization of hydrogen silsesquioxane films by using H2O plasma in a shing process. IITC 1998. In: Proceeding IEEE. 1998; pp. 48-50. |

| [11] | Feng J, Gao C, Wang B, Shen J. A novel process for inking the stamp with biomacromolecule solution used in reactive microcontact printing. Colloids Surf B Biointerfaces 2004; 36(3-4): 177-80. [http://dx.doi.org/10.1016/j.colsurfb.2004.06.001] [PMID: 15276634] |

| [12] | Yang CC, Chen WC. The structures and properties of hydrogen silsesquioxane (HSQ) by thermal curing. Mater Chem 2002; 12: 1138-41. [http://dx.doi.org/10.1039/b107697n] |

| [13] | Delamarche K, Schmid H, Bietsch A, et al. Transport mechanisms of alkanethiols during microcontact printing on gold. J Phys Chem 1998; 102(18): 3324-34. [http://dx.doi.org/10.1021/jp980556x] |