- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Open Electrical & Electronic Engineering Journal

(Discontinued)

ISSN: 1874-1290 ― Volume 13, 2019

Optimization and Design of Integrated Space Target

Mingxi Xue*

Abstract

Background & Objective:

The design and optimization of laser detection system based on MEMS (Micro-electro Mechanical Systems) scanning mirror is presented in the paper. According to requirements of application, it adopts the laser module to design the laser driver circuit, and the designed modulation circuit can satisfy the actual needs.

Method:

The designed information processing module is composed of the echo receiving module, signal amplification and filter circuit module, and the synchronous circuit of measuring angle and distance, etc.

Conclusion:

It gives out the distance decoding method and explores the method of capturing echo signal, which can fast and accurately calculate the distance and azimuth information of scanning.

Article Information

Identifiers and Pagination:

Year: 2017Volume: 11

First Page: 125

Last Page: 140

Publisher Id: TOEEJ-11-125

DOI: 10.2174/1874129001711010125

Article History:

Received Date: 04/05/2016Revision Received Date: 09/09/2016

Acceptance Date: 10/10/2016

Electronic publication date: 20/07/2017

Collection year: 2017

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this author at the Collaborative Innovation Center for Micro Nano Fabrication, Device and System State Key Laboratory of Precision Measurement Technology and Instruments Department of Precision Instrument Tsinghua University, Beijing, 100084, P. R. China, E-mail: Mingxixue_tsh@163.com

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 04-05-2016 |

Original Manuscript | Optimization and Design of Integrated Space Target | |

1. INTRODUCTION

In the scanning methods of the optical system, the traditional mechanical scanning system is the most widely adopted method, which includes mirror, prism scanning, etc. It has the advantages of simple structure and large scanning angle, etc. but its limitation is that it has large inertia of mechanical movement, low scanning speed, heavy weight, etc. The acoustic optic/electro-optic or binary optical scanning are emerging technologies in recent years, and their scanning speeds are very fast, but the scanning angles are relatively small and the power consumption is also large, and the most important aspect is that their efficiencies are low, and their driving structures are complicated and expensive. Therefore, in order to realize miniaturization, low power consumption, low cost and large scanning angle, and high stability two-dimensional MEMS scanning mirror equipment by using the MEMS technology, the basic and most important step is to develop the space laser scanning detection system.

In 1980, Kurt e. Petersen published the first article about MEMS scanning mirror [1C-C. Yang, K. Chao, and Y-R. Chen, "Development of multispectral image processing algorithms for identification of wholesome septicemic, and inflammatory process chickens", J. Food Eng., vol. 69, pp. 225-234, 2005.

[http://dx.doi.org/10.1016/j.jfoodeng.2004.07.021] ], known as the research work of MEMS scanning device which has been lasted for more than 30 years. The research of early MEMS scanning device focuses on the imaging, such as the confocal microscopy [2G. Petrie, "Airborne Digital Frame Cameras", GEO Informat., vol. 10, pp. 18-27, 2003.-7M.A. Schuster, and G. Strull, "A monolithic mosaic of photon sensors for solid state imaging application", IEEE Trans. Electron. Dev., vol. 13, pp. 907-912, 1966.

[http://dx.doi.org/10.1109/T-ED.1966.15867] ], the bar code recognition [8H.A. Yang, T.L. Tang, and S.T. Lee, "A novel coilless scanning mirror using eddy current lorentz force and magnetostatic force", J. Microelectromech. Syst., vol. 16, no. 3, pp. 511-520, 2007.

[http://dx.doi.org/10.1109/JMEMS.2007.896708] ], the fingerprint recognition [9H. Miyajima, N. Asaoka, and T. Isokawa, "A MEMS electromagnetic optical scanner for a commercial confocal laser scanning microscope", J. Microelectromech. Syst., vol. 12, no. 3, pp. 243-251, 2003.

[http://dx.doi.org/10.1109/JMEMS.2003.809961] ], etc. Other applications include the optical coherence tomography technique (OCT) [10S.H. Ahn, and Y.K. Kim, "Silicon scanning mirror of two DOF with compensation current routing", J. Micromech. Microeng., vol. 14, no. 11, pp. 1455-1461, 2004.

[http://dx.doi.org/10.1088/0960-1317/14/11/004] ], the retinal scan display (RSD) [11A. Jain, and H. Xie, "A single-crystal silicon micromirror for large bi-directional 2D scanning applications", Sens. Actuators A Phys., vol. 130, pp. 454-460, 2006.

[http://dx.doi.org/10.1016/j.sna.2005.10.030] ], printer, head-up display and the laser radar (LIDAR) in the automated production lines [12J. Singh, T. Gan, and A. Agarwal, "3D free space thermally actuated micromirror device", Sens. Actuators A Phys., vol. 123, pp. 468-475, 2005.

[http://dx.doi.org/10.1016/j.sna.2005.02.037] , 13X.H. Xu, and Y. Feng, "Design, fabrication and characterization of a bulk-PZT-actuated MEMS deformable mirror", J. Micromech. Microeng., vol. 17, no. 12, pp. 2439-2446, 2007.

[http://dx.doi.org/10.1088/0960-1317/17/12/008] ]. The Germany Fraunhofer institute studied the damping model, vacuum sealing [14N. Kikuchi, Y. Haga, and M. Maeda, "Piezolectric 2D micro scanner for minimally invasive therapy fabricated using femtosecond laser ablation", In: IEEE International Solid-State Sensors and Actuators Conference, 2003, pp. 603-606.

[http://dx.doi.org/10.1109/SENSOR.2003.1215545] , 15S.J. Kim, Y.H. Cho, and H.J. Nam, "Piezoelectrically pushed rotational micromirrors for wide-angle optical switch applications", In: 16th IEEE Annual International Conference on Micro Electro Mechanical Systems, 2003, pp. 263-266.

[http://dx.doi.org/10.1109/MEMSYS.2003.1189736] ], closed-loop control [16L.X. Zhou, M. Last, and V. Milanovic, "Two-axis scanning mirror for free-space optical communication between UAVs", In: IEEE/LEOS International Conference on Optical MEMS, 2003, pp. 157-158.

[http://dx.doi.org/10.1109/OMEMS.2003.1233514] ], angular sensor of electrostatic comb drive in their research work. In 2009, the IPMS group of Germany's Fraunhofer institute studied the integration piezoresistive angular sensor on two-dimensional micro MEMS scanning mirror, whose sensitivity can reach 0.42 mV/V°. Fraunhofer institute of Germany adopts the method of scattering force point, optimizing structure of supporting to improve the dynamic deformation of micro mirror. After improvement, the designed micro mirror dynamic flatness is five times higher than the design of the IPMS team. The resonance frequency of the micro mirror is 16 KHz. The diameter of mirror is 1 mm, the mechanical deflection angle is about 10°, which can satisfy the imaging demand of VGA (640×480 pixels), and the dynamic deformation is relative small. It is based on the design and optimization of laser detection system of MEMS scanning mirror, according to the need of goal application, it adopts the laser module to complete the design of laser driver circuit, and modulation circuit.

The designed system information processing module mainly includes echo receiving circuit design, signal amplification and filter circuit design, angle and distance synchronous circuit design, etc.

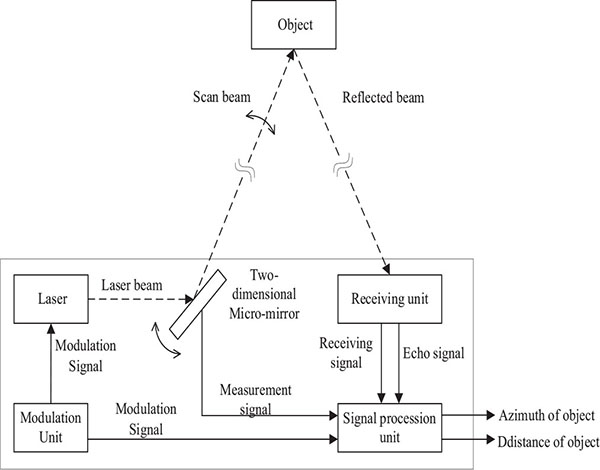

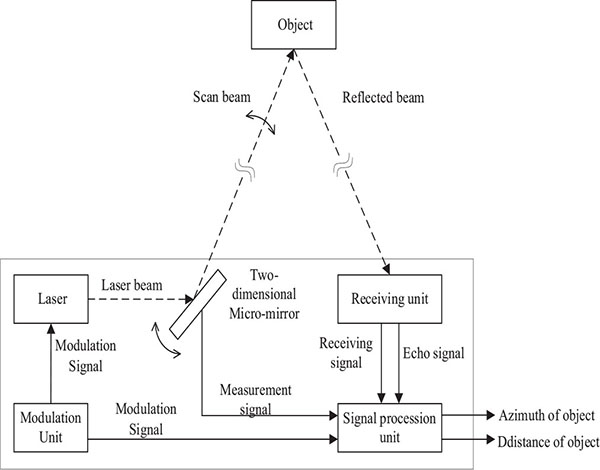

The design of detection system of non-cooperative target is shown in Fig. (1 ), which is mainly composed of laser, modulation unit, MEMS two-dimensional micro scanning mirror, piezoresistive measuring unit, the light receiving unit and a signal processing unit, et al. The principle target detection and measurement of system is that the modulation unit produces modulation signal to start the laser and the beam of laser scanning and detecting the measured target, through the reflex lenses of the micro two-dimensional scanning mirror, scanning beam can make detection to target objects, it will produce the reflected beams, which can be received by the photoelectric detector in the receiving unit, and it receives signal and echo signal and outputs them to the signal processing unit.

), which is mainly composed of laser, modulation unit, MEMS two-dimensional micro scanning mirror, piezoresistive measuring unit, the light receiving unit and a signal processing unit, et al. The principle target detection and measurement of system is that the modulation unit produces modulation signal to start the laser and the beam of laser scanning and detecting the measured target, through the reflex lenses of the micro two-dimensional scanning mirror, scanning beam can make detection to target objects, it will produce the reflected beams, which can be received by the photoelectric detector in the receiving unit, and it receives signal and echo signal and outputs them to the signal processing unit.

According to the measurement signal of deflection angle of the two-dimensional MEMS micro scanning mirror, the signal processing unit can calculate the relative orientation of target and according to the phase difference of the echo signal and modulation signal; it calculates the relative distance of the target and the specific location information of the target can be obtained.

The work of whole system involves the measuring of distance and angle. The main working principle of distance part is that the modulation circuit generates the driving laser source of the modulation signal. Loading a carrier on the emission laser, the beam emitted by the laser source will be launched to space through the scanning micro mirror. In the process of laser scanning in the space, if the scanning light meets the objects such as space debris, satellite, etc., it will be scattered. The scattering light beam of the receiving target of the echo receiving circuit can produce echo signal, and through the processing, the echo signal will present pulse signal form. In the comparison of the pulse echo signal and local signal used by the laser modulation, it adopts phase comparison ranging method to calculate the target relative distance. The main working principle of angular part is that the piezoresistive angle measuring circuit of scanning micro mirror produces the deflection angle signal, and triggers the angle information which can be collected by the echo receiving circuit, and it gets the time point of two-dimensional scanning deflection angle corresponding to the reflected beams.

|

Fig. (1) Diagram of the laser scanning measuring system. |

Through the target's relative distance information, two-dimensional deflection angle information, it can commonly get the space relative position information of target related system. On the basis of the principle prototype, the integration design and packaging of the scan detection system can be made. Detection system test is based on MEMS micro mirror, it can build test platform to complete the system test and field test accurately. The system environmental adaptability and typical environmental measurements are also researched.

2. MAIN DESIGN OF SYSTEM

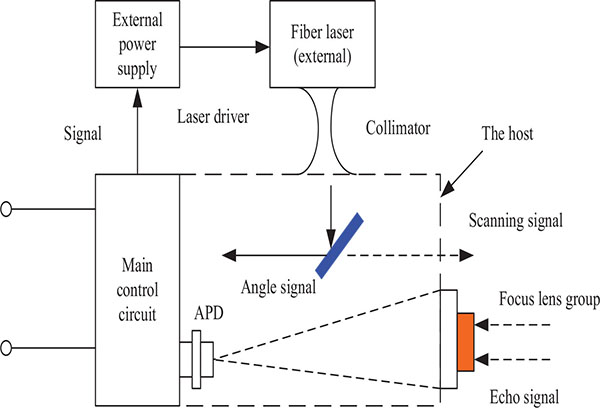

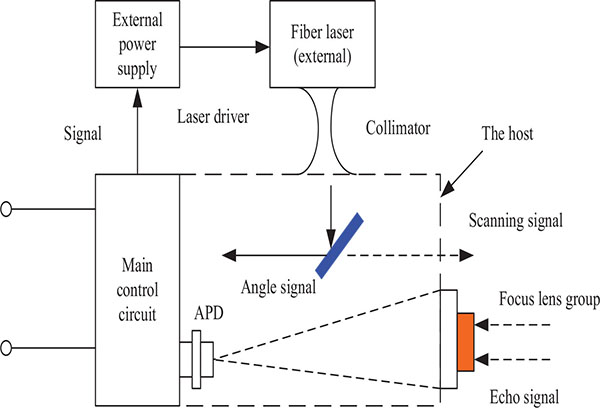

The integrated MEMS laser scanning imaging detection system mainly consists of two parts. Its host system includes the MEMS two-dimensional scanning mirror, the main control circuit system, APD (Avalanche Photo Diode), the fiber laser, the collimator and external drive power which is the external accessory, the half external attachments extended by the host is the focusing lens. The basic principle of the system is shown in Fig. (2 ).

).

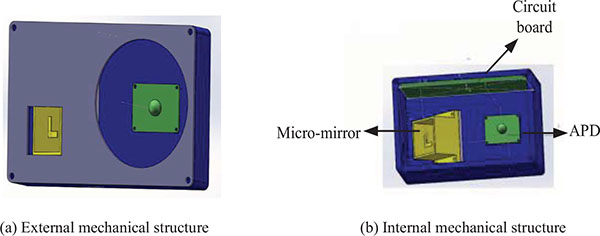

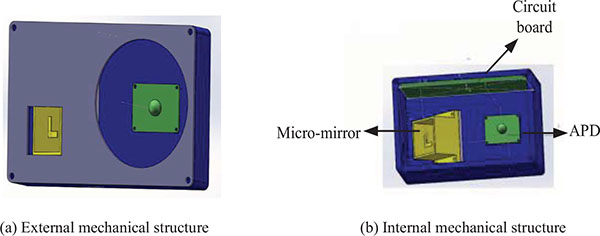

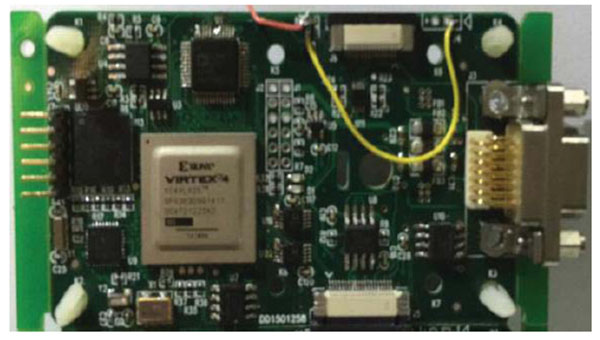

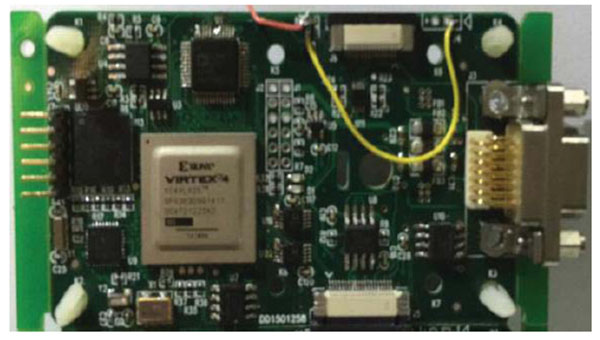

In the main control circuit, it outputs modulation signal, through two axis rotation of the MEMS two-dimensional scanning mirror, laser ranging signal of the outer fiber laser can reflect scan space target. The echo focuses on APD end face through focus lens group and it is converted to electrical signals. The time measurement module in the main control circuit can work out the object distance, and it is synchronous to the angle signal produced by the scan mirror to achieve the distance and azimuth information of the non-cooperative target. The internal structure of detection system is shown in Fig. (3 ).

).

|

Fig. (2) Integrated MEMS non-cooperative target detection system. |

|

Fig. (3) Detection system structure diagram. |

3. DESIGN OF DETECTION SYSTEM

3.1. Range Detection

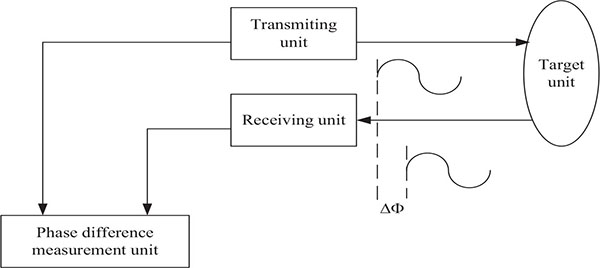

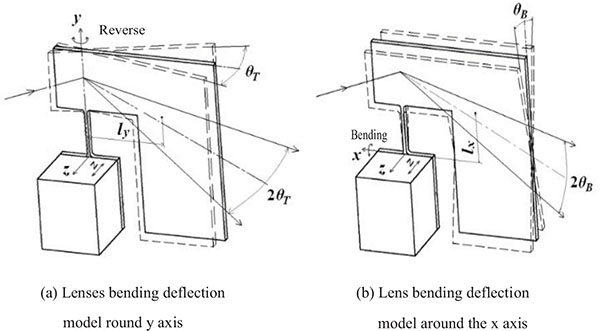

|

Fig. (4) Principle diagram of phase laser ranging method. |

It adopts the phase laser ranging method to design the laser ranging system, the system principle diagram is shown in Fig. (4 ). The working principle is that the frequency produced by the modulation circuit module is sine signal whose frequency is fs, it can module the laser in the laser emission module. At this time, among two types of signals of different frequencies in the reference signal (transmitting signal) and return signal (received signal), the two signals coexisted. The transmitting and received signals are connected into the signal processing module, through filtering, amplifier, shaping and phase module, the final distance results can be obtained.

). The working principle is that the frequency produced by the modulation circuit module is sine signal whose frequency is fs, it can module the laser in the laser emission module. At this time, among two types of signals of different frequencies in the reference signal (transmitting signal) and return signal (received signal), the two signals coexisted. The transmitting and received signals are connected into the signal processing module, through filtering, amplifier, shaping and phase module, the final distance results can be obtained.

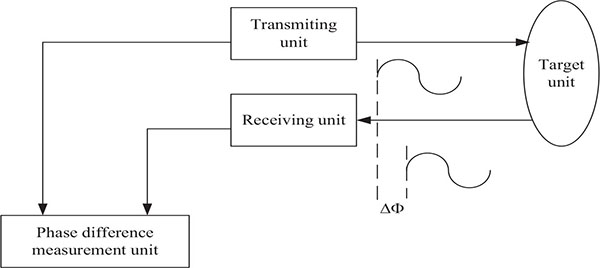

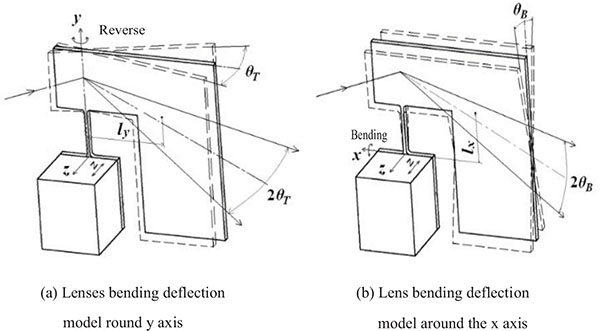

3.2. Design of Scanning Method

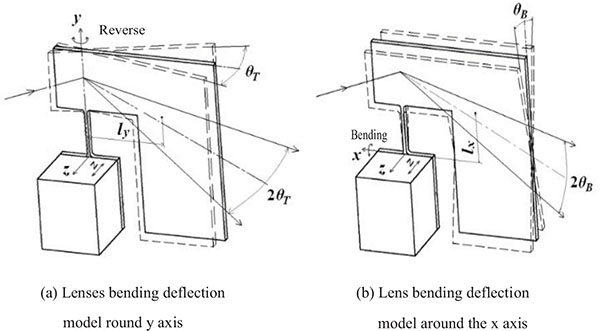

Detection system adopts two-dimensional piezoelectric MEMS scanning mirror to make the laser deflect and scan. The structure of micro two-dimensional scanning mirror is shown in Fig. (5 ), which is composed of the reflective lens, inertia generator, flexible beam, induced block and piezoresistive sensors, et al. When it exerted driving voltage composed by the resonant frequency in two scanning directions on the piezoelectric actuators at the same time, the lens will resonate around in the y and x axis direction at the same time so as to realize the large angle deflection scanning in two dimensions, its scanning range is about, as shown in Fig. (5

), which is composed of the reflective lens, inertia generator, flexible beam, induced block and piezoresistive sensors, et al. When it exerted driving voltage composed by the resonant frequency in two scanning directions on the piezoelectric actuators at the same time, the lens will resonate around in the y and x axis direction at the same time so as to realize the large angle deflection scanning in two dimensions, its scanning range is about, as shown in Fig. (5 ).

).

model around the x axis

|

Fig. (5) Structure of scanning system. |

3.3. Design of Basic Circuit

It produces the design of integrated circuit, and the electronic system can be divided into four relatively independent parts, namely the PZT drive module, angle signal processing module, APD module, phase ranging signal processing module and FPGA control module, et al.

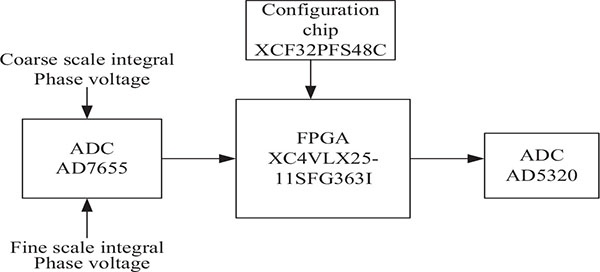

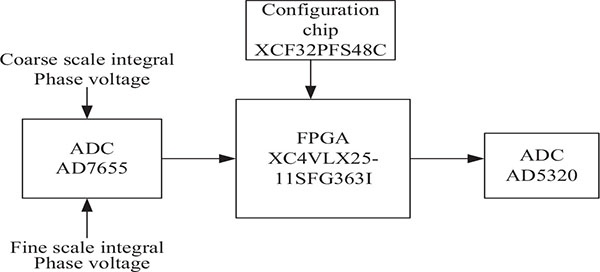

3.3.1. Master control module

The master control unit takes the FPGA as the core, it includes the synchronous sampling, and the global input clock is 25 MHz. The DAC used to drive micro mirror is the small package chip AD5320 which is made by ADI Company.

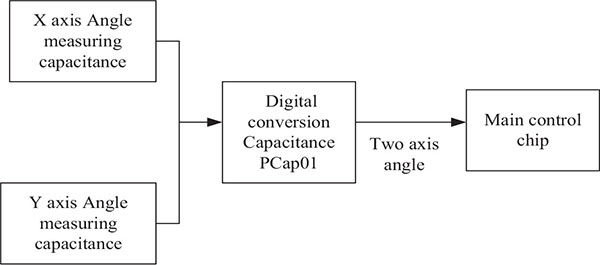

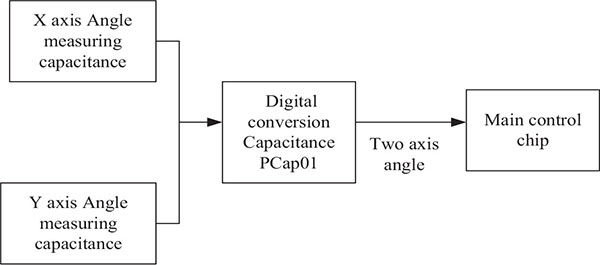

The measurement of pitch and azimuth angle of the micro mirror should adopt parallel sampling method, in order to improve its accuracy; it chooses 1MHz sampling rate and16 bit parallel ADC chip- AD7655, as shown in Fig. (6 ).

).

|

Fig. (6) Main control module block. |

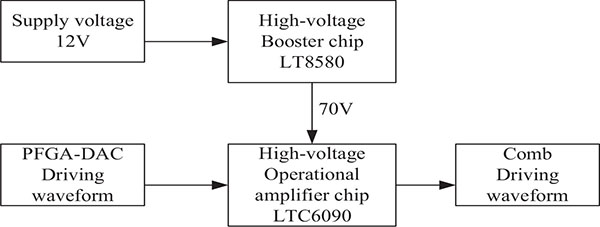

3.3.2. Micro Mirror Driver Module

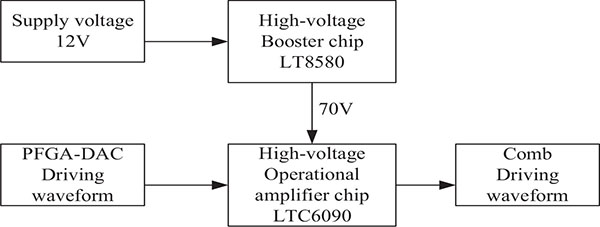

The comb drive module includes the comb drive high voltage generating circuit, comb drive high voltage amplification circuit, et al. The diagram of module block is shown in Fig. (7 ). The comb drive high voltage module adopts the booster chip LT8580, DAC output signals are low voltage, which are amplified by high gain rail-to-rail amplifier LTC6090 of LINEAR Company, and it can satisfy the requirement of high voltage driving signal of the comb drive, and amplitude of which should be 60V.

). The comb drive high voltage module adopts the booster chip LT8580, DAC output signals are low voltage, which are amplified by high gain rail-to-rail amplifier LTC6090 of LINEAR Company, and it can satisfy the requirement of high voltage driving signal of the comb drive, and amplitude of which should be 60V.

|

Fig. (7) PZT module block. |

3.3.3. Laser Driver Module

The laser driver module circuit is used to produce laser modulation signal to modulate the laser intensity, and at the same time the signal is also used as the reference signal of range phase. According to the requirements of the phase ranging, the output signal of modulation circuit should be 75 KHz. The DDS output signal is coupled into the following part, it chooses the OPA567 power amplifier of TI to drive large current phase ranging laser.

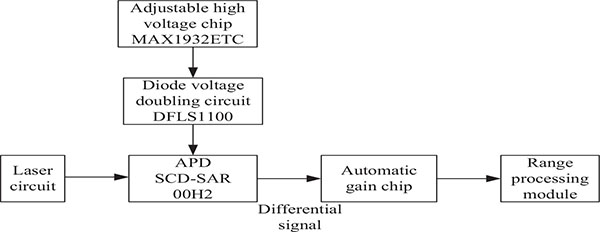

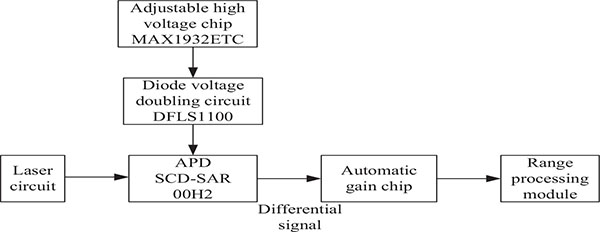

3.3.4. APD and Signal Module

The APD and signal module mainly include the adjustable APD voltage automatic gain control module, APD signal automatic gain control module and APD. In order to generate adjustable APD output function, it increases a three-time diode double voltage circuits based on the high pressure output of MAX1932ETC, and in order to curb the influence of temperature change on the output voltage, it adopts the thermal RT1 as temperature compensation device.

The automatic gain control circuit adopts TI-THS7530 automatic gain amplifier, the variable gain amplifier of which is from 11.6 dB to 46.5 dB, whose gain slope is 38.8 dB/V and the bandwidth is 300 MHz, which is the total differential input and output and it is quite suitable for the APD detector with a pre-amplifier, differential output (Fig. 8 ).

).

|

Fig. (8) APD module. |

3.3.5. Phase Ranging Signal Processing Module

The phase ranging signal processing module mainly involves the filter circuit and phase pulse generating circuit. It designs a band-pass filter whose center frequency is 75 KHz; it extracts the sine signal to prepare for the subsequent phase. In the phase detecting circuit, the output of band-pass filter whose center frequency is 75 KHz is put into high-speed comparator ADCMP600, and then the sine wave signal converted the square wave signal, and then it is imputed into the FPGA to make the phase to be verified and then the measurement results with large scale are obtained (Fig. 9 ).

).

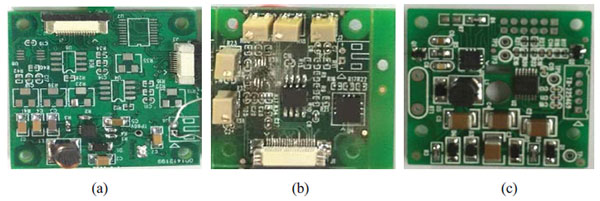

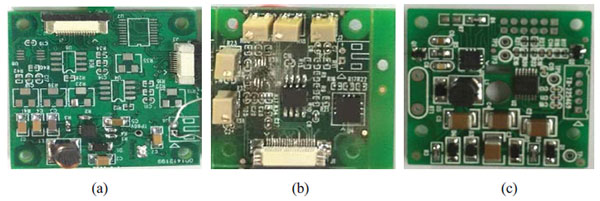

3.3.7. Integrated Design of System

The above part has completed principle of validation of range detection of system. In order to meet the requirements of the whole system miniaturization integration based on the original distance principles, it performs integration and miniaturization design for the whole system, as shown in Figs. (10 ) and (11

) and (11 ).

).

|

Fig. (10) Main control circuit. |

|

Fig. (11) Related circuit diagram. |

(a) Micro mirror drive and phase Angle measuring decoding module circuit

(b) Ranging module

(c) APD high voltage bias module

3.4. Optical System Design

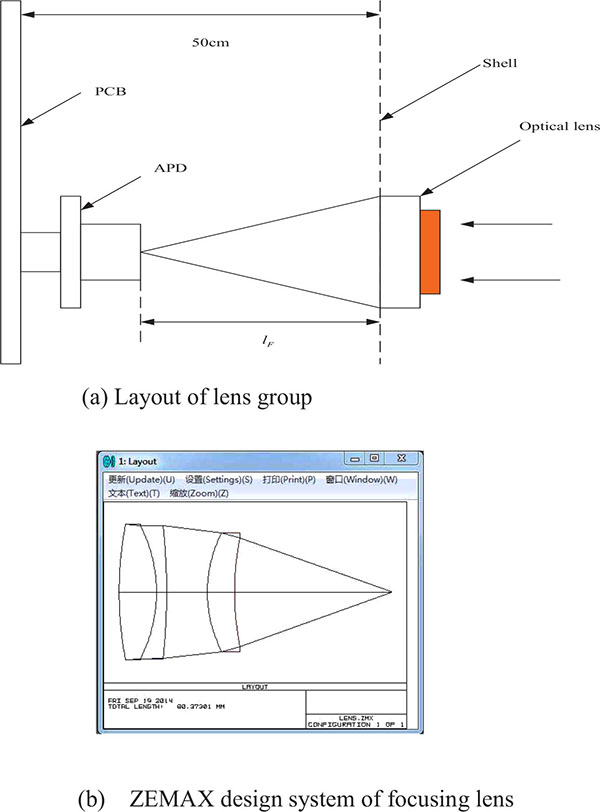

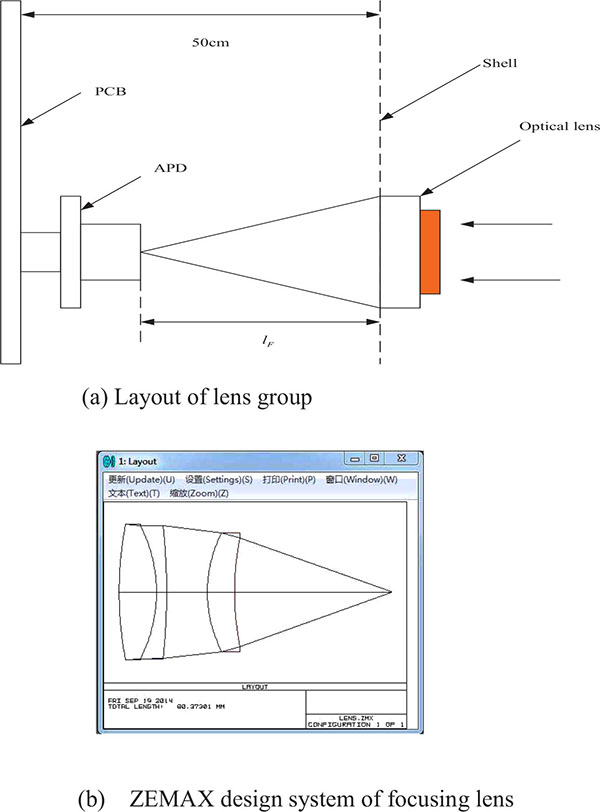

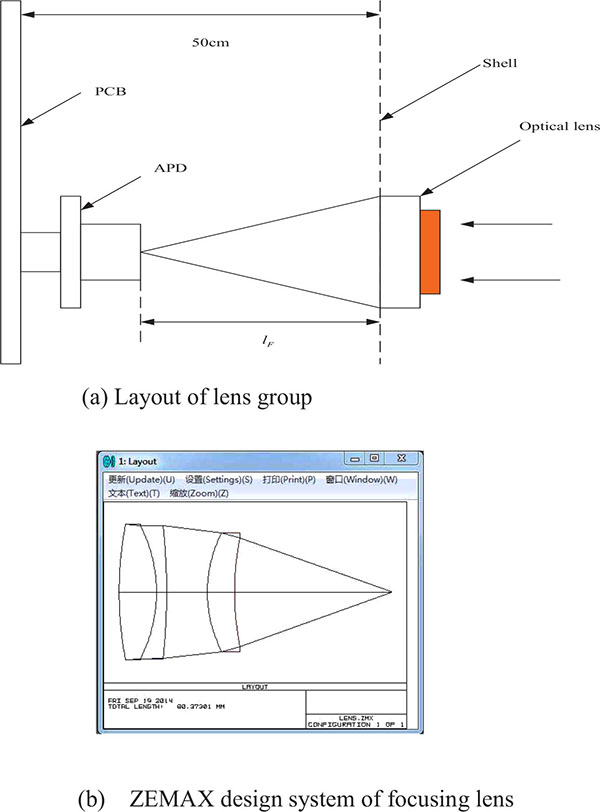

In order to increase the area of receiving optical signals in the system, it uses focused lens to gather receiving light and to make the focus point be on the photosensitive face of APD. The arrangement scheme of mirror group is shown in Fig. (12a ), the lens part is on the surface of the host, APD is put on PCB surface, whose space is lF of focused optical system rear cut distance, and the focusing effect can be improved through aberration correction.

), the lens part is on the surface of the host, APD is put on PCB surface, whose space is lF of focused optical system rear cut distance, and the focusing effect can be improved through aberration correction.

It adopts ZEMAX software in the design; it selects a set structure which is composed of the single chip's reflection and the double agglutination lens, as shown in Fig. (12 ). The optimized system focal length is f=62.13954 mm, the rear cut distance is lF=48.62075 mm, the diameter D is 40 mm, the size of the light spot is about 38.126μm, the incident window diameter less than the APD is 2.39 mm.

). The optimized system focal length is f=62.13954 mm, the rear cut distance is lF=48.62075 mm, the diameter D is 40 mm, the size of the light spot is about 38.126μm, the incident window diameter less than the APD is 2.39 mm.

|

Fig. (12) Design of ZEMAX system. |

|

Fig. (13) Fiber laser instrument. |

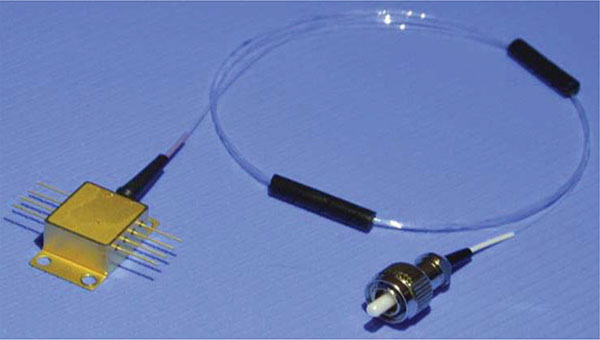

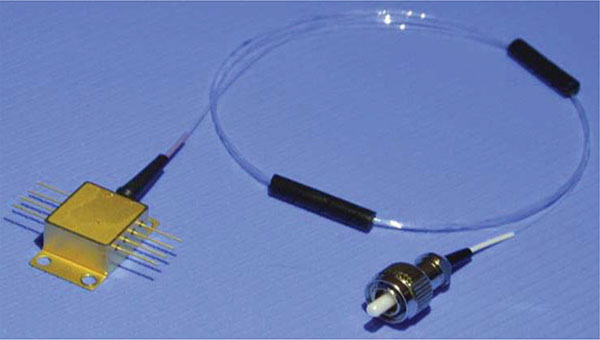

3.5. Selection of Laser Transmitting Module

The laser uses the fiber output semiconductor laser FC1064-150/06-SMD, which is shown in Fig. (13 ). The relevant technical parameters are as following: The center wavelength is 1064nm; it can undertake external signal modulation and the analog modulation bandwidth is 20 MHz, which is far above the modulation frequency 75KHz; the laser beam spread angle is approximately equal to 1 m/rad; the maximum output power of continuous wave (CW) is 150 mW.

). The relevant technical parameters are as following: The center wavelength is 1064nm; it can undertake external signal modulation and the analog modulation bandwidth is 20 MHz, which is far above the modulation frequency 75KHz; the laser beam spread angle is approximately equal to 1 m/rad; the maximum output power of continuous wave (CW) is 150 mW.

APD adopts SAR500-H2 silicon avalanche photodiode produced by Laser Components Company; the bandwidth is from 10 kHz to100MHz, which can satisfy the requirements of system frequency modulation (the frequency of 15 KHZ and 1.5 MHz). The working wavelength is from 400nm to 1100nm, its responsivity of 915 nm light signal is 2.7 ×106 V/W. (Fig. 14 )

)

|

Fig. (14) Avalanche diode 2-15 SAR500- H2. |

4. SYSTEM PERFORMANCE TEST

4.1. Mechanical Parameters Test

In the space application, it has strict requirements for the volume and quality of system. According to the requirements of indicators, it measures the overall dimension and quality of prototype of integration non-cooperative target detection system, and it uses the measurement methods of vernier caliper, thickness gauge to validate whether the system reach the requirement. After testing, the system prototype dimension is 50mm×50mm×80mm; the quality is 0.313 kg, which is conformed to the requirements of the system.

4.2. Power Consumption Test

According to the requirements of indicators, it tests the system power consumption and verifies whether it is satisfied with the requirements.

- It uses the test cable connecting the integration detection system, power supply and PC. Then the detection system is powered on, and the PC test program is started.

- Starting the PC test program, the integrated detection system is going into the working state, which regularly sends detection data frames to the PC and reads the output voltage and output current of digital power supply which is 5V, and then it calculates power and makes record. The system power consumption of test results is 2.85W, which is conformed to the requirements of the system.

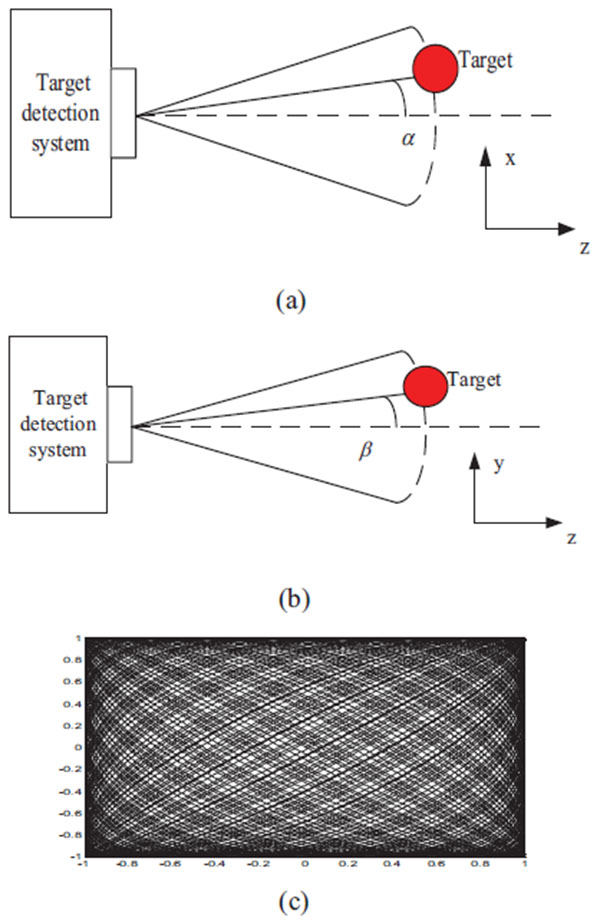

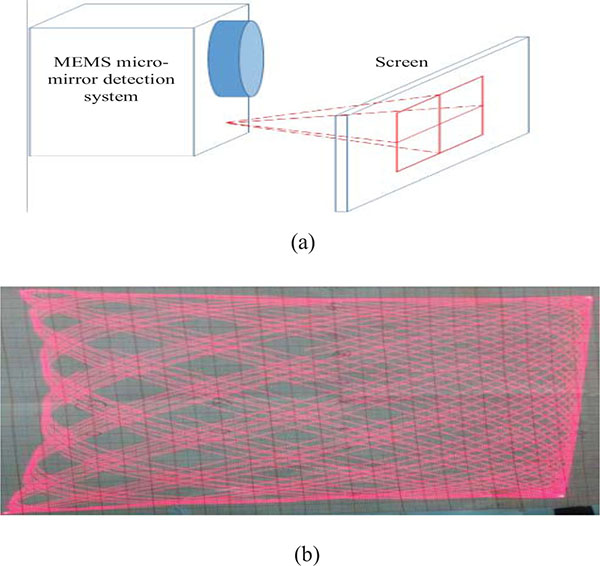

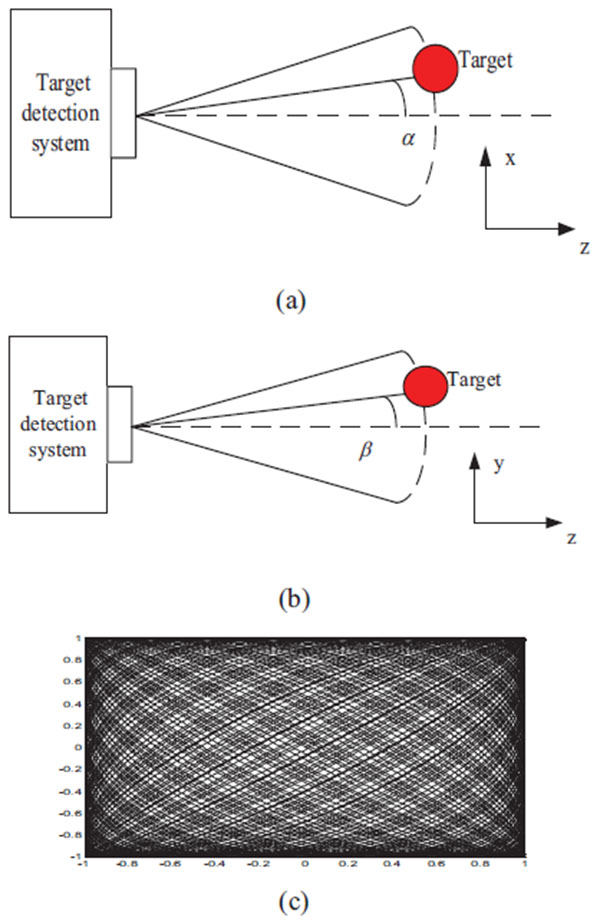

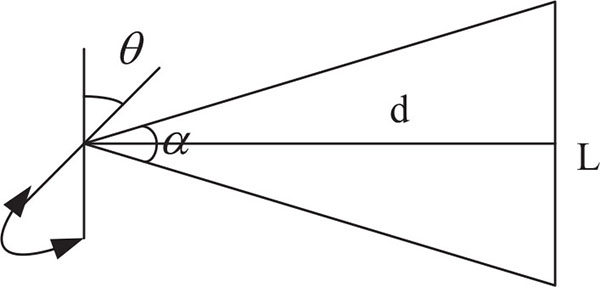

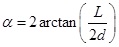

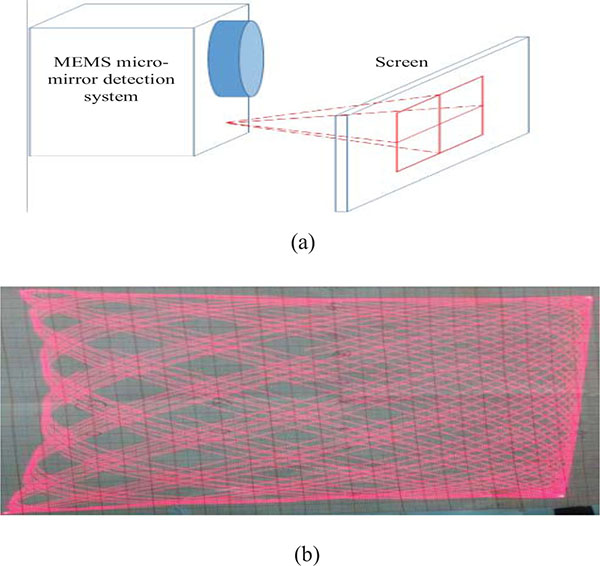

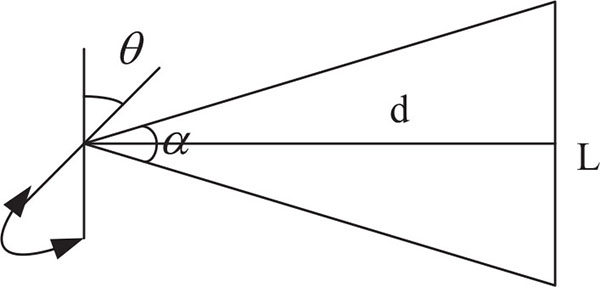

4.3. Detection Scanning Angle Test

The biggest deflection angle of the detection system is tested. The detection system makes scanning in two orthogonal directions, as shown in Figs. (15 ) and (16

) and (16 ). When the scanning is performed in two directions at the same time, it can form designed scanning probe. In the paper, it mainly tests the scanning range when the system makes scanning in two axis at the same time.

). When the scanning is performed in two directions at the same time, it can form designed scanning probe. In the paper, it mainly tests the scanning range when the system makes scanning in two axis at the same time.

|

Fig. (15) Scan sketch Integrated detection system. |

The scan angle testing principle of integrated detection system is shown in figure, and the test method is as follows:

- The integrated non-cooperative target detection system and light screen are installed onto the optical platform, it makes light center and screen overlapped when detection system makes no scanning and lets the light center and screen to be vertical, it measures the distance between detection system and screen center.

-

We click the start button to make the detection system working in the condition of scanning, the MEMS micro-mirror makes the two-dimensional scanning in the detection system and measure the scanning scope on the light screen grid, in which the conversion principle of the light length and optical scanning angle on quadrille paper is shown in Fig. (17

), the optical scanning angle is as follows:

), the optical scanning angle is as follows:

|

(1) |

|

Fig. (16) MEMS micro-mirror detection. |

|

Fig. (17) Scan angle conversion principle Integrated detection system. |

The test results are shown in Table 1, the maximum scan angle range can be up to ±21.2 °-±20.5°, which is conformed to the requirements of the system.

4.4. Angle Detection Accuracy

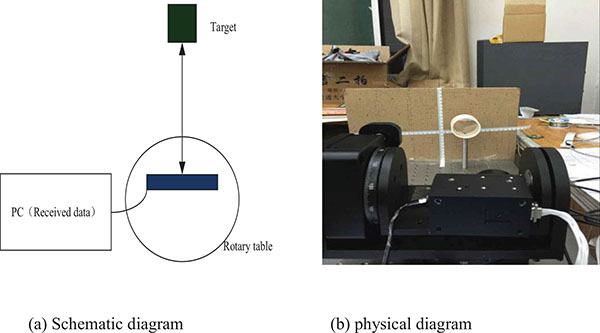

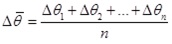

The detection accuracy of integrated angle detection system is tested, as shown in Fig. (18 ); the test method is as follows:

); the test method is as follows:

- Adjusting the light path, when MEMS micro mirror of detecting system is in the non-scanning mode, it makes the laser from the detection system reflecting to the target through the micro mirror, which is called as zero state

- Open the system, the system is under a scanning state, the angle target relative to the micro mirror is a two-dimensional angle, it can be represented by two angles (angle of bend, torsion angle), first it ensures that one angle target relative to the micro mirror is constant, turning the turntable, and then another angle target relative to the micro mirror will be changed.

The rotating platform rotate respectively to 2.5°; 5°;7.5°; 10 °; 12.5 °; 15° in both sides and it collects a total of 12 collection data points, and they can be directly read from screen of PC, and at the same time it can record and read the deviation angle.

- Changing the micro mirror coordinate system, it repeats step 2, it makes measurement of the target position of another direction angle.

- According to the formula (2), it can respectively calculate the arithmetic mean value of two directions angular error.

|

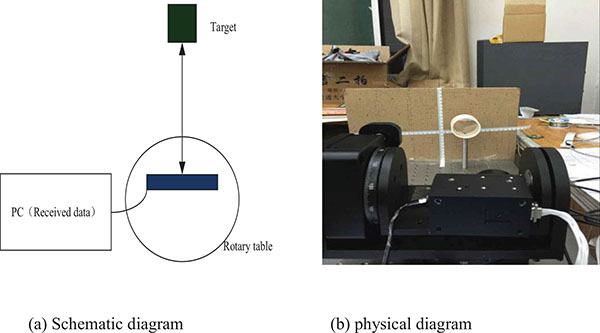

(2) |

|

Fig. (18) Angle measuring accuracy test of integrated detection system. |

The test results of angle measuring accuracy are shown in Table 2, and two axis angle measuring accuracy is respectively ±0.185 ° and ± 0.171 °,which are better than the index requirements.

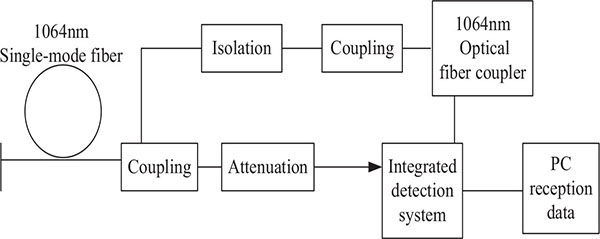

4.5. Test of Range Detection Accuracy

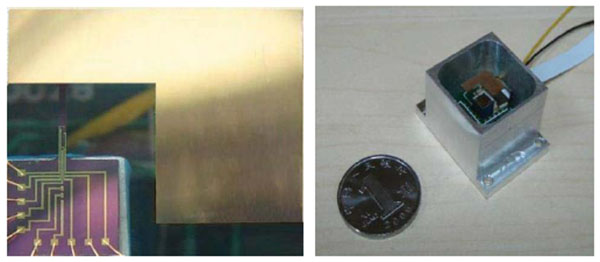

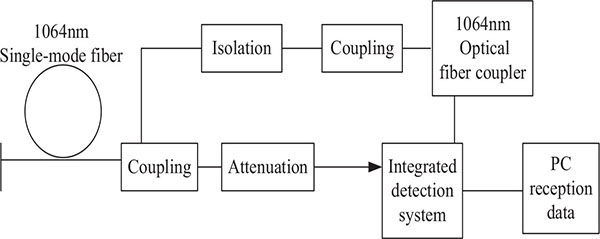

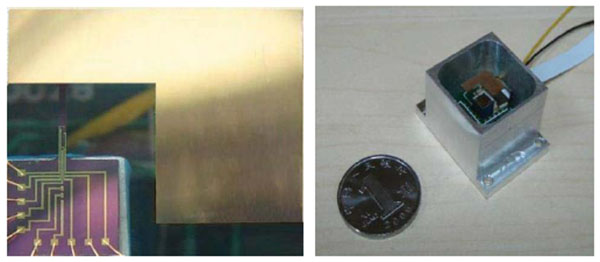

The ranging precision of integrated detection system was tested in the paper. The test device can simulate the reflection of target 1km outside space, as shown in Figs. (19 ), (20

), (20 ), and (21

), and (21 ), Photos of the MEMS Micro-scanning mirror are presented and the test method and sequence are as follows:

), Photos of the MEMS Micro-scanning mirror are presented and the test method and sequence are as follows:

|

Fig. (19) Simulation testing principle of space distance precision integrated detection system. |

|

Fig. (20) Ranging accuracy experiment. |

- Starting the integrated detection system, it loads driver and modulation signal to the optical fiber coupled laser, and through the hand held optical power meter detects shot light power and record the data;

- Turning off the laser, it couples FC emergent plug of optical fiber coupled laser and insulator entrance plugs of optical fiber simulation ranging system (1km optical fiber, the optical path:1477+ 5m) by FC adapter outlet with fiber coupled laser FC). Once again it loads the same modulation signal to the laser, it adjusts attenuator of the optical simulation ranging system outputs to make the incident light power of emergence and the ratio is 2.2756 ×10-4, when it is used to simulate the attenuation of 1mrad angle beam reflected by extension target1.5 km away.

- Making the attenuator output part be aim to the focus lens of the alignment integrated detection system, it reads the angle value through the PC display and simultaneously records deviation of readings and path;

- Repeating steps (2)~(3), it records 10 measurement results of 1km optical fiber target of integrated detection system, according to the type (3), the average value can be calculated, and reference accuracy index can be obtained accordingly;

|

(3) |

5 The optical fiber analog ranging system is replace with 500m (optical fiber: 739±5m), repeat steps (1)~(4).

The test results are shown in Table 3, when optical path is 1477±5m, the ranging error is about ±3.1m, when optical path is 739m±5m, the ranging error is about ±2.4 m, which is far better than the requirements.

|

Fig. (21) Photo of the MEMS Micro-scanning Mirror. |

5. KEY TECHNOLOGY AND RELATED INDICATORS

In the laser detection system based on MEMS scanning mirror design, the focus is the breakthrough of high SNR weak echo signal detection of integrated circuit design, high scan speed quick and high precision angle measuring distance measurement method research and its circuit implementation, and engineering prototype can be completed.

Model of the system is analyzed, and the after multistage enlarging echo signal is passed through FPGA for signal processing, finally, it can realize the weak echo signal detection, and the system miniaturization can be achieved; it adopts FPGA as the master control chip, using the parallel I/O mouth for data reading and writing, the angle and distance of parallel processing can be realized, target orientation detection can also be made.

In the integrated MEMS non-cooperative target detection system, its quality is less than 500 g, volume is less than 50 ×50×80 mm3, and power consumption is not higher than 3W. Scan range is more than 40°×40°, the azimuth measurement precision is better than 0.2°, ranging accuracy is about 50 m; Temperature range is from -20ºC to 40ºC, 20Krad (Si) can meet the requirement of anti-radiation ability, the mechanical conditions are shown in Tables 4 and 5.

CONCLUSION

- According to actual needs of space target angle measurement, it puts forward a decoupling bi-axial angle measuring sensor MEMS scanning mirror, on the basis of the principle prototype and scanning coverage analysis, it optimizes the device structure and the resonance frequency, engineering prototype design is completed.

- It adopts MEMS two-dimensional scanning mirror and active laser ranging technology, the integrated non-cooperative target detection system which has a small volume, light quality, low power, and scanning speed and so on, which is suitable for small space target detection, and it provides powerful means for the application of space satellite.

- Individual technical indicators of the system are still need to further optimized, take the volume for example, index factor should be 50×50 ×80 mm3, if detection range is greater than 40°×40°, then the numerical aperture of system is at least more than 0.34. In the receiving system the aperture of system should be 40 mm, when focal length is 60 mm, numerical aperture should be 0.31, the received aperture angle is 36.8°, as it is strictly unable to meet the requirements of maximum detection range. Short edge of the system is only 50 mm in size, however, if it takes the size of optical margin pressure and mechanical installation into consideration, it will make the system unable to match the larger aperture receiving system.

- In the design, the detecting light source is taken as the external component, which is independent of the system, and in order to make the system integration degree be low, it still needs a higher degree of integration.

CONFLICT OF INTEREST

The author confirms that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

Declared none.

REFERENCES

| [1] | C-C. Yang, K. Chao, and Y-R. Chen, "Development of multispectral image processing algorithms for identification of wholesome septicemic, and inflammatory process chickens", J. Food Eng., vol. 69, pp. 225-234, 2005. [http://dx.doi.org/10.1016/j.jfoodeng.2004.07.021] |

| [2] | G. Petrie, "Airborne Digital Frame Cameras", GEO Informat., vol. 10, pp. 18-27, 2003. |

| [3] | Y. Lei, Z. Shi-hu, and L. Zhou-hui, "A Convertible Aerial Camera System Integrated With Film and CCD Image Sensor", In: International Symposium on Photoelectronic Detection and Imaging, 2007, p. 662414. |

| [4] | S. Morrison, "A New Type of photosensitive Junction Device", Solid-State Electron., vol. 5, pp. 485-494, 1963. [http://dx.doi.org/10.1016/0038-1101(63)90033-9] |

| [5] | W.S. Boyle, and G.E. Smith, "Charge coupled semiconductor devices", Bell Syst. Tech. J., vol. 49, pp. 587-583, 1970. [http://dx.doi.org/10.1002/j.1538-7305.1970.tb01790.x] |

| [6] | J. Horton, R. Mazza, and H. Dym, "The scanner- A solid-state image scanner", Proc. IEEE, vol. 5, pp. 1513-1528, 1964. [http://dx.doi.org/10.1109/PROC.1964.3440] |

| [7] | M.A. Schuster, and G. Strull, "A monolithic mosaic of photon sensors for solid state imaging application", IEEE Trans. Electron. Dev., vol. 13, pp. 907-912, 1966. [http://dx.doi.org/10.1109/T-ED.1966.15867] |

| [8] | H.A. Yang, T.L. Tang, and S.T. Lee, "A novel coilless scanning mirror using eddy current lorentz force and magnetostatic force", J. Microelectromech. Syst., vol. 16, no. 3, pp. 511-520, 2007. [http://dx.doi.org/10.1109/JMEMS.2007.896708] |

| [9] | H. Miyajima, N. Asaoka, and T. Isokawa, "A MEMS electromagnetic optical scanner for a commercial confocal laser scanning microscope", J. Microelectromech. Syst., vol. 12, no. 3, pp. 243-251, 2003. [http://dx.doi.org/10.1109/JMEMS.2003.809961] |

| [10] | S.H. Ahn, and Y.K. Kim, "Silicon scanning mirror of two DOF with compensation current routing", J. Micromech. Microeng., vol. 14, no. 11, pp. 1455-1461, 2004. [http://dx.doi.org/10.1088/0960-1317/14/11/004] |

| [11] | A. Jain, and H. Xie, "A single-crystal silicon micromirror for large bi-directional 2D scanning applications", Sens. Actuators A Phys., vol. 130, pp. 454-460, 2006. [http://dx.doi.org/10.1016/j.sna.2005.10.030] |

| [12] | J. Singh, T. Gan, and A. Agarwal, "3D free space thermally actuated micromirror device", Sens. Actuators A Phys., vol. 123, pp. 468-475, 2005. [http://dx.doi.org/10.1016/j.sna.2005.02.037] |

| [13] | X.H. Xu, and Y. Feng, "Design, fabrication and characterization of a bulk-PZT-actuated MEMS deformable mirror", J. Micromech. Microeng., vol. 17, no. 12, pp. 2439-2446, 2007. [http://dx.doi.org/10.1088/0960-1317/17/12/008] |

| [14] | N. Kikuchi, Y. Haga, and M. Maeda, "Piezolectric 2D micro scanner for minimally invasive therapy fabricated using femtosecond laser ablation", In: IEEE International Solid-State Sensors and Actuators Conference, 2003, pp. 603-606. [http://dx.doi.org/10.1109/SENSOR.2003.1215545] |

| [15] | S.J. Kim, Y.H. Cho, and H.J. Nam, "Piezoelectrically pushed rotational micromirrors for wide-angle optical switch applications", In: 16th IEEE Annual International Conference on Micro Electro Mechanical Systems, 2003, pp. 263-266. [http://dx.doi.org/10.1109/MEMSYS.2003.1189736] |

| [16] | L.X. Zhou, M. Last, and V. Milanovic, "Two-axis scanning mirror for free-space optical communication between UAVs", In: IEEE/LEOS International Conference on Optical MEMS, 2003, pp. 157-158. [http://dx.doi.org/10.1109/OMEMS.2003.1233514] |

Endorsements

Browse Contents

Table of Contents

- INTRODUCTION

- MAIN DESIGN OF SYSTEM

- DESIGN OF DETECTION SYSTEM

- SYSTEM PERFORMANCE TEST

- KEY TECHNOLOGY AND RELATED INDICATORS

- CONCLUSION Although it can shorten the focal length, etc. in order to meet the requirements of numerical aperture, thickness of the center of the lens itself should also be increased, however, it will increase the extension of the original attachment size, in return, it can affect the scan window 40 visual scopes.