- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Open Fuels & Energy Science Journal

(Discontinued)

ISSN: 1876-973X ― Volume 11, 2018

Latest Trends and Challenges In Proton Exchange Membrane Fuel Cell (PEMFC)

Mohammed Jourdani*, Hamid Mounir, Abdellatif El Marjani

Abstract

Background:

During last few years, the proton exchange membrane fuel cells (PEMFCs) underwent a huge development.

Method:

The different contributions to the design, the material of all components and the efficiencies are analyzed.

Result:

Many technical advances are introduced to increase the PEMFC fuel cell efficiency and lifetime for transportation, stationary and portable utilization.

Conclusion:

By the last years, the total cost of this system is decreasing. However, the remaining challenges that need to be overcome mean that it will be several years before full commercialization can take place.This paper gives an overview of the recent advancements in the development of Proton Exchange Membrane Fuel cells and remaining challenges of PEMFC.

Article Information

Identifiers and Pagination:

Year: 2017Volume: 10

First Page: 96

Last Page: 105

Publisher Id: TOEFJ-10-96

DOI: 10.2174/1876973X01710010096

Article History:

Received Date: 16/08/2017Revision Received Date: 01/11/2017

Acceptance Date: 10/11/2017

Electronic publication date: 20/12/2017

Collection year: 2017

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this author at the Mohammadia School of Engineers, UniversityMohammed V inRabat, Morocco; Tel: (+212)671093580; Fax: (+212)537778853; E-mail: jourdani.mohammed@gmail.com

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 16-08-2017 |

Original Manuscript | Latest Trends and Challenges In Proton Exchange Membrane Fuel Cell (PEMFC) | |

1. INTRODUCTION

The numerous environmental problems which affect the world today are making the entire society and particularly the scientific community to achieve sustainable development and keep on progressing in a more respectful way towards our planet [1Belmonte, N.; Luetto, C.; Staulo, S.; Rizzi, P.; Baricco, M. Case Studies of Energy Storage with Fuel Cells and Batteries for Stationary and Mobile Applications. Challenges, 2017, 8(1), 9.-3Huggins, R. Energy Storage: Fundamentals, Materials and Applications., (1st ed.;. ), 2015, ]. In this context, the substitution of the actual main energy resources by others that may completely satisfy human needs is the key point that should be settled in the nearest future. Fuel cells are the device through which this aspect finds the most likely solution, as it is possible to obtain electric energy from clean fuels with high efficiency and no CO2 emissions. Amongst the different types of fuel cells, Proton Exchange Membrane Fuel Cell (PEMFC) seem to be the ones which show features that adapt better to mobile applications (cars, laptops, mobile phones, etc.) [4Tenson, J.; Baby, R. Recent advances in proton exchange membrane fuel cells: A review. Int. Adv. Res. J. Sci., 2017, 4(Special Issue), 6.-7Jourdani, M.; Mounir, H.; El Marjani, A. Compilation of Factors Affecting Durability of PEMFC). IRSEC’14 IRSEC’14 IEEE Conference,, 2014.October 17-19Ouarzazate, Morocco], and therefore are of increasing interest for a wide variety of manufacturers. PEMFC technology in recent years continued throughout 2016 in terms of the number of PEMFCs units shipped as shown in Fig. (2 ) [8Maizia, R.; Dib, A.; Thomas, A. The Fuel Cell Industry Review. Fuel Cell Today, 2012, 21]. In fact, PEMFC have many advantages such as low operating temperature, sustained operation at a high current density, low weight, compactness, the potential for low cost and volume, long stack life, fast start-ups and suitability for discontinuous operation [9Neto, R.C.; Teixeira, J.C.; Azevedo, J.L. Thermal and electrical experimental characterisation of a 1 kW PEM fuel cell stack. J. Hydrog. Energy, 2013, 38(13), 5348-5356.

) [8Maizia, R.; Dib, A.; Thomas, A. The Fuel Cell Industry Review. Fuel Cell Today, 2012, 21]. In fact, PEMFC have many advantages such as low operating temperature, sustained operation at a high current density, low weight, compactness, the potential for low cost and volume, long stack life, fast start-ups and suitability for discontinuous operation [9Neto, R.C.; Teixeira, J.C.; Azevedo, J.L. Thermal and electrical experimental characterisation of a 1 kW PEM fuel cell stack. J. Hydrog. Energy, 2013, 38(13), 5348-5356.

[http://dx.doi.org/10.1016/j.ijhydene.2013.02.025] ]. PEMFC technology is well suited to a range of sizes and is also used with a variety of different fuel types, when suitably processed to generate hydrogen. As such it finds application from the small, sub-watt scale, right through to the megawatt scale, as seen in Fig. (2 ), 88% of total fuel cell shipments in 2016 were PEMFC. In addition, many technologies utilizing PEMFC for different applications are currently under development [8Maizia, R.; Dib, A.; Thomas, A. The Fuel Cell Industry Review. Fuel Cell Today, 2012, 21], and are soon expected to enter the market in force worldwide [10Fuel Cells Section. 2016]. However, the promising achievements and plausible prospects of PEMFCs, the remaining problems mean that it is still a long way before they can successfully and economically replace the various traditional energy systems. This review introduces and discusses some of the remaining challenges and some cases of the latest research on the application tests of small and middle ranged PEMFCs to real systems such as transportation, Stationary application, and portable (Table 1). This review discusses the papers published recently, which is expected to provide useful and helpful information on the development of PEMFC technologies.

), 88% of total fuel cell shipments in 2016 were PEMFC. In addition, many technologies utilizing PEMFC for different applications are currently under development [8Maizia, R.; Dib, A.; Thomas, A. The Fuel Cell Industry Review. Fuel Cell Today, 2012, 21], and are soon expected to enter the market in force worldwide [10Fuel Cells Section. 2016]. However, the promising achievements and plausible prospects of PEMFCs, the remaining problems mean that it is still a long way before they can successfully and economically replace the various traditional energy systems. This review introduces and discusses some of the remaining challenges and some cases of the latest research on the application tests of small and middle ranged PEMFCs to real systems such as transportation, Stationary application, and portable (Table 1). This review discusses the papers published recently, which is expected to provide useful and helpful information on the development of PEMFC technologies.

Current (2016) Challenges of PEMFC [20Zhang, Xu.; Guo, L.; Hongtan, L. Recovery mechanisms in proton exchange membrane fuel cells after accelerated stress tests. J. Power Sources, 2015, 296, 327-334.

[http://dx.doi.org/10.1016/j.jpowsour.2015.07.063] ].

2. RECENT ADVANCES ON PROTON EXCHANGE MEMBRANE

2.1. Fuel Cell

2.1.1. Advances in Modeling and Studying of PEMFC

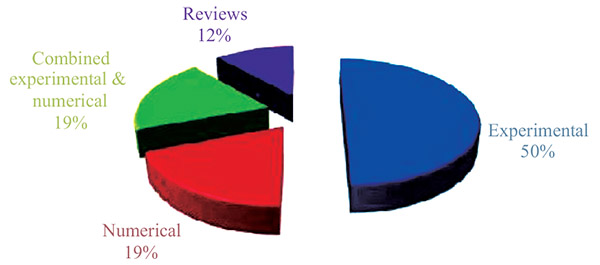

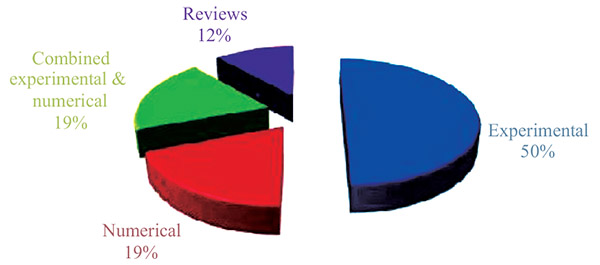

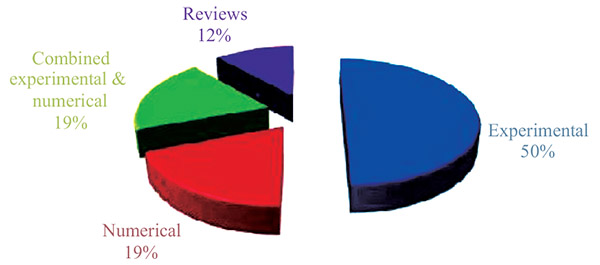

In the literature, several modeling and experimental studies have been reached in order to develop this technology more. In the present review as shown in Fig. (1 ). A total of 26 papers are taken from the previous studies [11Tenson, Ti.; Baby, Ra. Recent Advances in Proton Exchange Membrane Fuel Cells: A Review. Int. Adv. Res. J. Sci., 2017, 4(Special Issue), 6.]. Out of these, thirteen papers focus on experimental, five on numerical, five on combined experimental and numerical investigations and three explains various reviews of fuel cell.

). A total of 26 papers are taken from the previous studies [11Tenson, Ti.; Baby, Ra. Recent Advances in Proton Exchange Membrane Fuel Cells: A Review. Int. Adv. Res. J. Sci., 2017, 4(Special Issue), 6.]. Out of these, thirteen papers focus on experimental, five on numerical, five on combined experimental and numerical investigations and three explains various reviews of fuel cell.

- Experimental Investigations

A large number of researchers have experimentally analyzed the PEMFCs as well as performance level. Yusuke, et al. [12Hiramitsu, Y.; Kobayashi, K.; Hori, M. Gas diffusion layer design focusing on the structure of the contact face with catalyst layer against water flooding in polymer electrolyte fuel cell. J. Power Sources, 2010, 95(22), 7559-7567.

[http://dx.doi.org/10.1016/j.jpowsour.2010.05.067] ] analyzed the effect of humidity in PEMFC. Therefore, high humidity level in PEMFC helps to achieve high ion conductivity and so cell performance but this causes water flooding. Powerful water management is required for the effective working of PEMFC. Humidity factor and water flooding mainly rely on the pore framework of GDL. Experimentally, it was observed that water damage was prevented with a GDL with a smaller pore structure. A research carried out by Giovanni, et al. [13Dotelli, G.; Omati, L.; Stampino, P.; Grassini, P.; Brivio, D. Investigation of gas diffusion layer compression by electrochemical impedance spectroscopy on running polymer electrolyte membrane fuel cells. J. Power Sources, 2011, 196(21), 8955-8966.

[http://dx.doi.org/10.1016/j.jpowsour.2011.01.078] ] analyzed the GDL compression by Electrochemical Impedance Spectroscopy. The authors used two GDLs based on same carbon dioxide cloth with and without MPL. It was observed that ohmic and mass copy resistance was sensibly afflicted by embrace compression of the GDL. Chien, et al. [14Hung, C.H; Chiu, C.H; Wang, S Ultra thin gas diffusion layer development for PEMFC. Int. J. Hydrogen Energy., 2012, 37(17), 12805-12812.

[http://dx.doi.org/10.1016/j.ijhydene.2012.05.110] ] reported the style of an ultra-thin GDL. Carbon-fiber-reinforced polymer newspaper can be used as the GDL. Thickness of GDL was in the range of 100 um. Results show that 3 and 6mm size carbon-fiber-reinforced polymer have more strength than 12mm because long carbon materials bonding is not more powerful. Schweiss, et al. [15Schweiss, R.; Steeb, M.; Wilde, M. Enhancement of proton exchange membrane fuel cell performance by doping micro porous layers of gas diffusion layers with multiwall carbon nanotubes.

. J. Power Sources., 2012, 220, 79-83.

[http://dx.doi.org/10.1016/j.jpowsour.2012.07.078] ] conducted the style of MPL with multiwall CO2 nanotubes using wet chemical substance method. Multiwall nanotubes assist in improving mass copy and electronic conductivity. Multiwall nanotubes show excellent electric and heat conductivity. Yuka, et al. [16Yuka, O.; Sounai, A.; Michio, H. Prolongation of lifetime of high temperature proton exchange membrane fuel cells. J. Power Sources, 2013, 241, 87-93.

[http://dx.doi.org/10.1016/j.jpowsour.2013.03.122] ] focused their attention to the cell voltage and life time. Long life time with high cell volts is one of the fundamental requirements that is expected from the gas cells. Cell voltage reduces as time increases due to depletion of the phosphoric acid. Chemically cross connected poly membranes were used. Test results show that cells with ordinary PEMFC show 10% decrease in cell voltage with given period where new mixlinked poly membranes helped cells shows only 4. 4% decrease in cellular voltage for the same time period. Jason et al. [17Morgan, M.; Ravindra, D. Understanding the gas diffusion layer in PEMFCs. 1. How its structural characteristics affect diffusion and performance. J. Power Sources, 2014, 251, 269-278.

[http://dx.doi.org/10.1016/j.jpowsour.2013.09.090] ] address the challenges of PEMFCs and how to overcome these challenges. Variables that are specifically related to GDL and Micro Porous Layer (MPL) were examined in this experimental research. Duration of a gas cell mainly depends on and membrane durability. Key parameters of GDL which influence the cell performance are reactant permeability, product permeability, electrical conductivity, heat conductivity, mechanical support. GDL thickness is an important factor. Thicker GDL provides better protection for the membrane, gives mechanical durability, has longer diffusion pathway lengths, and gives more thermal and electrical level of resistance. Satoki, et al. [18Hirakata, S.; Hara, M.; Kakinuma, K. Investigation of the effect of a hydrophilic layer in the gas diffusion layer of a polymer electrolyte membrane fuel cell on the cell performance and cold start behavior. Electrochim. Acta, 2014, 120, 240-247.

[http://dx.doi.org/10.1016/j.electacta.2013.12.050] ] introduce a hydrophilic layer in the GDL. Hydrophilic layer is located between MPL and the carbon paper. Test was conducted at normal operating temperature and sub-freezing temperature conditions. GDL with hydrophilic layer shows high performance as compared to conventional GDL. Kong, et al. [19Kong, I.; Choi, J.; Kim, S.; Lee, E.; Kim, M. Experimental study on the selfhumidification effect in proton exchange membrane fuel cells containing double gas diffusion backing layer. Appl. Energy, 2015, 145, 345-353.

[http://dx.doi.org/10.1016/j.apenergy.2015.02.027] ] focused their studies in self-humidification result in PEMFCs. Uniform organized GDL and heterogeneous organized GDL utilized for the experiment purpose. Heterogeneous organized GDL shows better electric performance. Reliability of fuel cell and related investigations was conducted by Zhang et al. [20Zhang, Xu.; Guo, L.; Hongtan, L. Recovery mechanisms in proton exchange membrane fuel cells after accelerated stress tests. J. Power Sources, 2015, 296, 327-334.

[http://dx.doi.org/10.1016/j.jpowsour.2015.07.063] ]. Strength is the main component of the important challenges for the commercialization of PEMFCs. Research aims to recover deficits due to kinetic and mass transport after more rapid stress tests. Platinum O2 reduction and platinum reattachment is the key reason for the kinetic recovery, where associated with oxide groupings causes mass transport. Effects show that performance destruction can be recovered by performance recovery methods. Restoration methods assist to increase the life time. Kong, et al. [21Kong, I.; Jung, A.; Kim, B.; Baik, K.; Kim, M. Experimental study on the start-up with dry gases from normal cell temperatures in self-humidified proton exchange membrane fuel cells. Energy, 2015, 93, 57-66.

[http://dx.doi.org/10.1016/j.energy.2015.09.014] ] reported start up characteristics of gas cells. Start-up characteristics were analyzed at different circulation arrangements, mainly co-flow and counter flow, counter circulation arrangement has terrific starting point up characteristics. It was observed that reactant flow arrangement has significant influence on the stable operation of fuel cells. Heterogeneous porosity and their effects were analyzed by Banarjee, et al. [22Banerjee, R.; Hinebaugh, J.; Liu, H.; Yip, R.; Ge, N.; Bazylak, A. Heterogeneous porosity distributions of polymer electrolyte membrane fuel cell gas diffusion layer materials with rib-channel compression. Int. J. Hydrogen Energy, 2016, 41(33), 14885-14896.], along with the bilayer structure of GDL. X-Ray computed tomography is used to study the structure of the bilayer GDL. This is an NDT method. Many other techniques commonly used for the study of structure of GDLs are mercury intrusion porosimetry, atomic force microscopy, optical profilometry etc. Results show that porosity distribution has a strong basis for the calculation of thermal and electrical conductivities, permeability and diffusivity. Iryna, et al. [23Zenyuk, V.; Parkinson, Y.; Connolly, G.; Weber, Z. Gas-diffusion-layer structural properties under compression via X-ray tomography. J. Power Sources, 2016, 328, 364-376.

[http://dx.doi.org/10.1016/j.jpowsour.2016.08.020] ] mainly focused their attention towards the compression and porosity. GDL porosity measurement is very challenging because of their thin, compressible and inhomogeneous geometry. Result shows that porosity decreases with compression of GDL. Porous structure and mass transfer effects were analysed by Takahiro Suzuki, et al. [24Suzuki, T.; Tanaka, H.; Hayase, M.; Tsushima, S.; Hirai, S. Investigation of porous structure formation of catalyst layers for proton exchange membrane fuel cells and their effect on cell performance. Int. J. Hydrog. Energy, 2016, 41(44), 20326-20335.]. In this study porous structure formation of catalyst layer was analysed. Porous structure has significant effect on the mass transfer in the electrode. Experiment was conducted at different hot pressing pressure, which varied from 0.5 to 10MPa. Results show that pore size has more importance than porosity with respect to cover potential in the polarization curve.

- Numerical Investigations

Huang, et al. [25Huang, Yu.; Cheng, Ch.; Wang, Xi.; Jang, Ji. Effects of porosity gradient in gas diffusion layers on performance of proton exchange membrane fuel cells. Energy, 2010, 35(12), 4786-4794.

[http://dx.doi.org/10.1016/j.energy.2010.09.011] ], reported the interaction between heat and water transport in PEMFCs. Performance mainly depends on the platinum metal, but cost of platinum metal is very high. Results show that porosity gradient enhances the gas transport which in turn improves cell performance. Fanglong [26Zhu, F. Fractal geometry model for through-plane liquid water permeability of fibrous porous carbon cloth gas diffusion layers. J. Power Sources, 2013, 243, 887-890.

[http://dx.doi.org/10.1016/j.jpowsour.2013.06.079] ] developed the design of fractal model, which is used to predict the liquid water permeability of the GDL. Here, GDL having parallel and perpendicular combination of channels with the fluid flow direction is used. Fractal model is more suitable for the prediction of permeability of GDL. Dahua et al. [27Shou, D.; Fan, J.; Ding, F. Effective diffusivity of gas diffusion layer in proton exchange membrane fuel cells. J. Power Sources, 2013, 225, 179-186.

[http://dx.doi.org/10.1016/j.jpowsour.2012.10.039] ] developed 1 dimensional, 2 dimensional and 3 dimensional models which are used to analyze the diffusivity. Influences of porosity, fiber distribution and fiber orientation were analyzed; Results show that randomly distributed fibers have lower diffusivity when compared with orderly distributed fibers. Diffusivity can increase by using less chemical binders and prevention of chemical binders. Degradation rate was reported by Taegon et al. [28Kang, T.; Kim, M.; Kim, J.; Jun, Y. Numerical modeling of the degradation rate for membrane electrode assemblies in high temperature proton exchange membrane fuel cells and analyzing operational effects of the degradation. Int. J. Hydrogen Energy, 2015, 40(15), 5444-5455.]. Degradation rate was analysed in high temperature PEMFCs. Effects of degradation with respect to temperature were considered. Results give an idea about how temperature changes affect life time and average performance of fuel cell and also it was observed that high temperature PEMFCs degradation rate at initial time is low and then increases rapidly later. Straubhaar, et al. [29Straubhaar, B.; Pauchet, J.; Prat, M. Modelling of condensation in gas diffusion layers of proton exchange membrane fuel cells. Int. J. Heat Mass Transfer, 2015, 102, 891-901.

[http://dx.doi.org/10.1016/j.ijheatmasstransfer.2016.06.078] ] developed Pore Network Model. This is used to find out the liquid water formation by vapor condensation in the GDL at an operating temperature of 80°C. Pore Network Model is very essential and useful to find out the transfer phenomena in GDL. This model is used to stimulate the condensation in GDL. Water transfer is connected with heat transfer because condensation in GDL is due to the temperature difference in GDL.

- Combined Experimental and Numerical investigations

The combined experimental and numerical investigation on fuel cells conducted by Enju, et al. [30Nishiyama, E.; Murahashi, T. Water transport characteristics in the gas diffusion media of PEMFC – Role of the microporous layer. J. Power Sources, 2011, 196(4), 1847-1854.

[http://dx.doi.org/10.1016/j.jpowsour.2010.09.055] ], mainly focused on the role of micro porous layer and how it affects the water transport system. Study mainly focused on establishing relationship between capillary pressure and liquid saturation. It was found that analysis of capillary pressure of MPL has a significant role in the cell operation especially in high humidity conditions. Tamayol, et al. [31Tamayol, A.; McGregor, F.; Bahrami, M. Single phase through-plane permeability of carbon paper gas diffusion layers. J. Power Sources, 2014, 204, 94-99.] mainly deals with PTFE content and mechanical compression of PEMFCs. Permeability was calculated with the help of PTFE content and mechanical compression. Experimental analysis shows a reverse relationship between the permeability and PTFE content. Also, the authors address the main challenges associated with PEMFCs, main challenges are reliability, cost, power density, performance and membrane lifetime. Mass transport loss which is related to GDL permeability results in the reduction of maximum power density. Zhang, et al. [32Zhang, Y.; Verma, A.; Pitchumani, R. Optimum design of polymer electrolyte membrane fuel cell with graded porosity gas diffusion layer. Int. J. Hydrogen Energy, 2016, 41(20), 8412-8426.

[http://dx.doi.org/10.1016/j.apenergy.2016.05.057] ] analysed the effects of variation in local current density. Numerical model was used to analyse the optimum porosity distribution. Experimental study was used to analyse the local current density and porosity distribution. Optimum porosity was found to decrease with the increase in temperature and increase with the increase in cell voltage. Reduction in the size of fuel cells was conducted by Kong, et al. [33Kong, I.; Jung, A.; Kim, M. Investigations on the double gas diffusion backing layer for performance improvement of self- humidified proton

exchange membrane fuel cells.

Appl. Energy, 2016, 176, 149-156.

[http://dx.doi.org/10.1016/j.apenergy.2016.05.057] ]. External humidifier is one of the important component which will help to maintain proper humidification in the cell. Self-humidification is achieved and avoids external humidifier, which will help reduce the size of PEMFCs. This study gives support to the design of self-humidified PEMFCs. Shiro, et al. [34Tanaka, S.; Bradfield, W. Numerical and experimentally study of the effects of the electrical resistance and diffusivity under clamping pressure on the performance of a metallic gas-diffusion layer in polymer electrolyte fuel cells J. Power Sources., 2016, 330, 273-284.

[http://dx.doi.org/10.1016/j.apenergy.2010.09.030] ] suggest the usage of metal sheet GDL. Perforated metal sheet was used. Stainless steel 316L was the material selected. Numerical model conducted with the help of simulation software STAR-CCM+. Results show that metallic GDL gives sufficient strength and thickness to the GDL structure. But one of the drawbacks of this metallic sheet GDL was the chances of corrosion which will reduce the lifetime of the cell.

- Various Reviews on Fuel Cell Designs

|

Fig. (1) Chart of apportioning of the literature. |

Yun et al. [35Wang, Y.; Chen, S.; Chen, S.; Mishler, J.; Cho, S. A review of polymer electrolyte membrane fuel cells: Technology, applications and needs on fundamental research. Appl. Energy, 2011, 88(4), 981-1007.

[http://dx.doi.org/10.1016/j.apenergy.2010.09.030] ] conducted a review about the application of fuel cells, research fundamentals and major challenges in the field of PEMFCs. Linfa, et al. [36Linfa, P.; Peiyun, Yi.; Xinmin, Lai Design and manufacturing of stainless steel bipolar plates for proton exchange membrane fuel cells. Int. j. hydrog. Energy., 2014, 39(36), 21127-21153.] focused their attention towards the bipolar plates of fuel cells. Usually, graphite plates were used as the bipolar plates, but in this paper authors reported the usage of Stainless steel bipolar plates and its significance. Flow field design, micro forming process, joining process and coating process are the steps in stainless steel bipolar plates formation. Bipolar plates should have good electrical conductivity, high resistance to corrosion, mechanical stability, light weight, cheap etc . Graphite and its composites having these characteristics but its high production cost, brittleness etc. are some of the drawbacks. Authors suggested that stainless steel bipolar plates are more effective than graphite bipolar plates. Wang, et al. [37Wang, Y.; Leung, D.; JinXuan, H. Wang A review on unitized regenerative fuel cell technologies, part-A: Unitized regenerative proton

exchange membrane fuel cells. Renew. Sustain. Energy Rev., 2016, 65, 961-977.

[http://dx.doi.org/10.1016/j.rser.2016.07.046] ] reported about Unitized Regenerative Fuel Cells (URFC). URFC consist of fuel cell part and electrolyser part and these two parts are unitized in a single electrochemical cell. Advantages of URFC are lower capital cost, simpler structure, higher specific energy, no need for auxiliary heating. URFCs have wide application in aviation, aerospace, power supply and transportationetc.

2.1.2. Commercial Advance

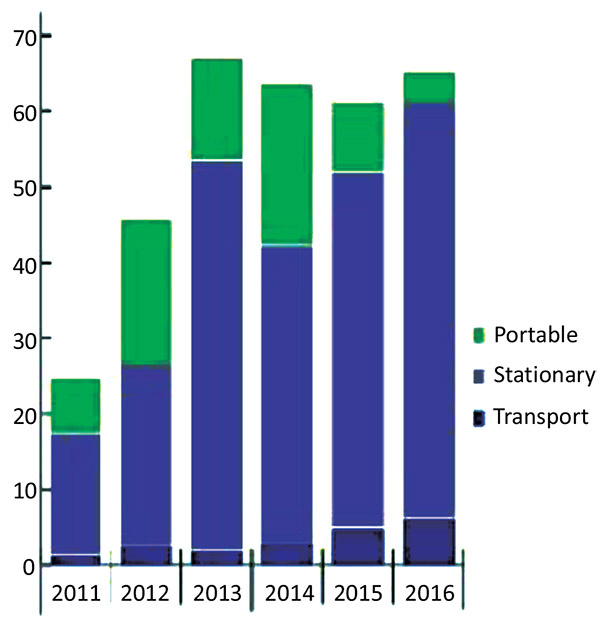

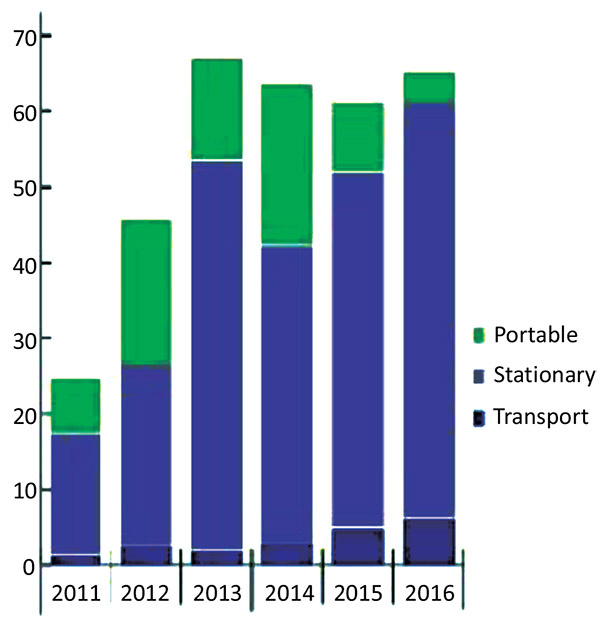

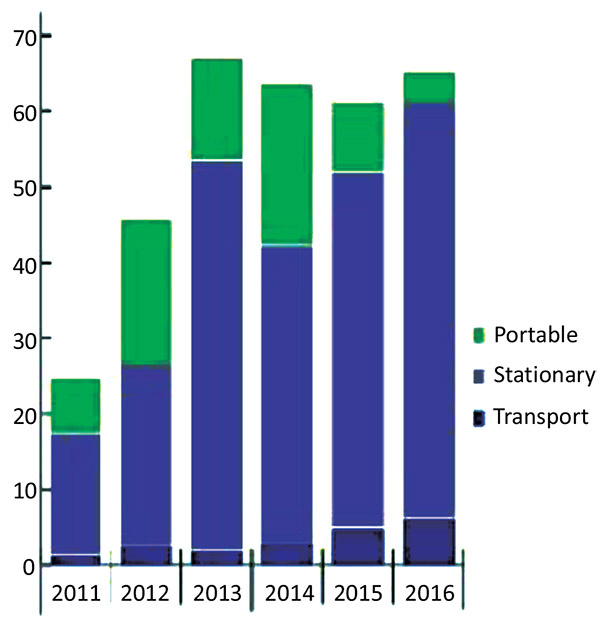

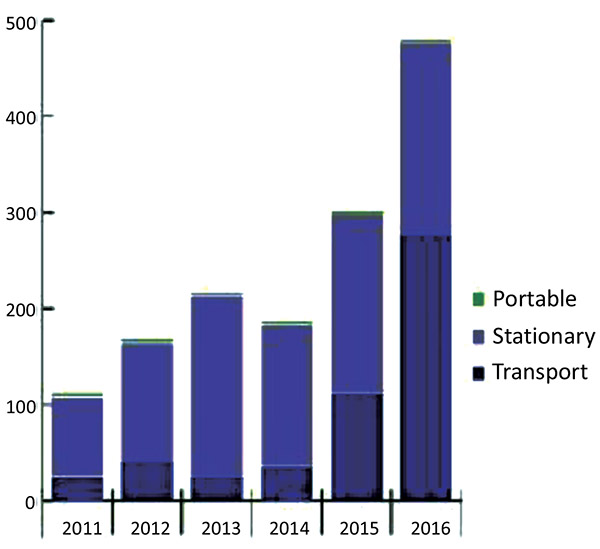

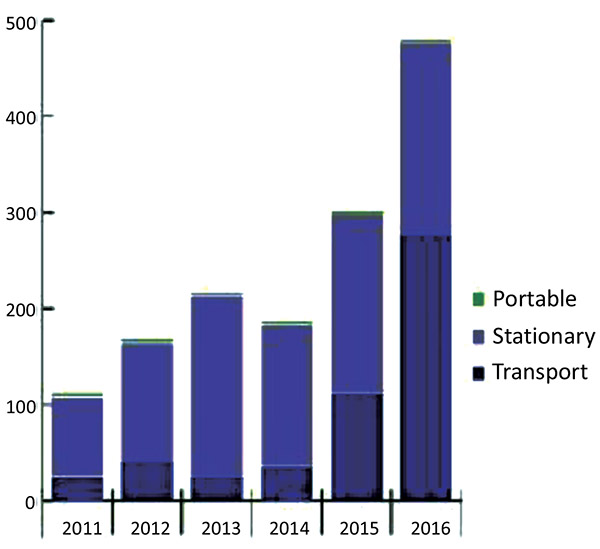

2017 will be another record year for shipments. We estimate that 65 thousand fuel cell systems totalling 478 MW will be shipped in 2016 [8Maizia, R.; Dib, A.; Thomas, A. The Fuel Cell Industry Review. Fuel Cell Today, 2012, 21]. While the total number of units in Fig. (2 ) has remained relatively stable, the MW shipped represents a two-thirds increase over 2015 (Fig. 3

) has remained relatively stable, the MW shipped represents a two-thirds increase over 2015 (Fig. 3 ). This is driven largely by fuel cells for transport. Although stationary shipments increased 10% up to 200MW, transport shipments have more than doubled year on year, reaching nearly 280MW.

). This is driven largely by fuel cells for transport. Although stationary shipments increased 10% up to 200MW, transport shipments have more than doubled year on year, reaching nearly 280MW.

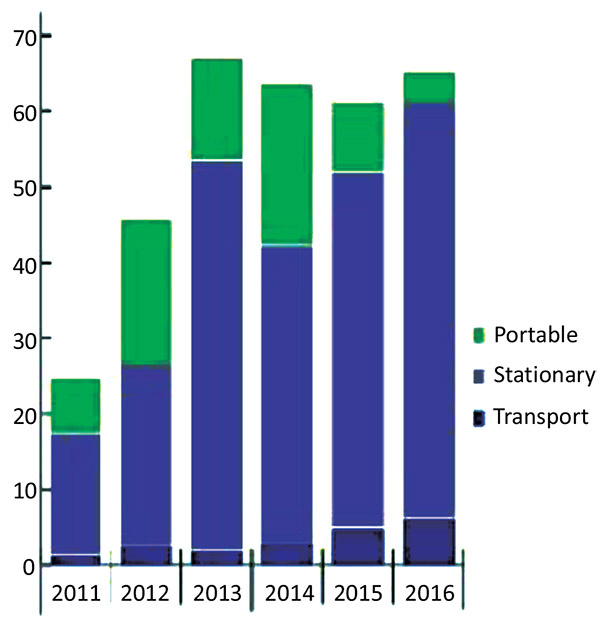

Importantly, for the first time, the transport sector will surpass the stationary sector. This increase is primarily driven by the introduction of the Toyota Mirai in Japan and California and to a lesser extent in Europe. 2,700 Mirais are expected to be delivered between its launch in 2014 and the end of Japan’s 2016 fiscal year. Honda and Hyundai will also deliver more cars, and in total just over 2,200 will go to customers in calendar year 2016. Since the stacks of ten such fuel cell cars add to a MW of PEM fuel cell capacity, it is easy to see what has driven this increase. 2016 has seen continued stable growth in materials handling – a trend already observed over several years. Over 10,000 fuel cell powered forklifts are in operation, with nearly 4,000 added in 2016. Mass deployment in this segment comes essentially from Plug Power, but several companies globally offer fuel cell lift trucks. In 2016 Nuvera Fuel Cells, now part of Hyster-Yale Materials Handling and hence with excellent channels to market, began shipping their own systems. Transport’s trajectory seems somewhat clear, as Toyota and others follow their plans to increase vehicle deliveries to the market by 2020. Simultaneously, the predicted shipments from Ballard, Hydrogenics, Plug Power and others to China for commercial vehicles, buses and trams will underpin growth in this area in the coming years, while Chinese manufacturers build their capabilities. Shipments of large systems for trams in China and trains in Germany give further reassurance. Shipments of stationary fuel cells will see reasonable growth in numbers (from 47,000 to about 55,000 units), and MW (184 to 200 MW) in 2016. The former will be largely determined by Japan’s Ene-Farm programme for domestic micro-CHP systems, whilst the latter is driven by the output of the larger system producers, FuelCell Energy and its Korean partner POSCO, Bloom Energy, Doosan Fuel Cell and Fuji Electric. 2017 should see some increase following from the German subsidy programme described elsewhere. Nevertheless, stationary power will not be as dominant as previously, as the relatively low levels of publicly announced orders date in 2016 bear out. The portable sector appears to have taken another tumble in 2016. Although the combined power of this sector amounts to much less than a MW, unit numbers are likely to fall from 2015, itself a substantial reduction on 2014 (Fig. 1 ). Although the auxiliary, off-grid and back-up power markets appear to be steady or growing, the long-discussed growth in consumer chargers always seems to be somewhere in the future.

). Although the auxiliary, off-grid and back-up power markets appear to be steady or growing, the long-discussed growth in consumer chargers always seems to be somewhere in the future.

|

Fig. (2) Units shipped by application 2011 - 2016 (1,000 units). |

|

Fig. (3) Megawatts shipped by application 2011 – 2016. |

3. CHALLENGES

3.1. Commercialization Challenges

To be competitive on capital cost, Fuel Cell (FC) system costs must be reduced by a factor of two, and stack life increased by a factor two. However, operating costs will still be much higher as hydrogen production costs are around $2.5 to $3 and delivered hydrogen are unlikely to be below $4/kg [38David, L.; Duleep, K.G. Status and outlook for the U.S. non-automotive fuel cell industry: Impacts of government policies and assessment of future opportunities., 2011.]. Developing low cost supplies of hydrogen appears to be critical for larger deployment of FC powered vehicles. At present FC system has to be competed with another proven technology of batteries. For FCs to compete effectively with batteries shorter refueling time and elimination of battery replacement should be emphasized. Independent analysis commissioned by the Carbon Trust, UK predicts current polymer fuel cell technology will cost $49/kW in automotive applications when manufactured at mass scale (i.e. 500,000 units per year). However, in order to be competitive with internal combustion engine vehicles, automotive fuel cells must reach approximately $36/kW. Cost savings can be achieved by reducing material costs (notably platinum use), increasing power density, reducing system complexity and improving durability. There are several challenges to wide-spread commercialization of the technology, including a number of technical barriers to overcome.

3.2. Technical Challenges

The cost of the stack is a function of material, engineering and manufacture techniques. Material selection not only depends on the suitability of the material for the functions but also the manufacturability and the cost must be taken into consideration.

The key US DOE targets for 2015 were as follows: - To reduce electro/catalyst loading and increase activity.

- Increase durability/ reduce degradation.

- Optimize electrode design.

- Improve impurity tolerance at anode.

The research is extremely complex, as reducing cost while using a noble metal can only be achieved by using physically less metal and uniformity is required to maintain the activity across the membrane active area. The membrane, catalyst layer and Gas Diffusion Layer (GDL) can be regarded as a single entity, often called a Membrane Electrode Assembly (MEA). The catalyst layer is 5-25μm thick, where the catalyst is supported on an electrically conductive structure, which is interconnected to both the GDL and the membrane. This is where the Oxygen Reduction Reaction (ORR) and the Hydrogen Oxidation Reaction (HOR) takes place at the anode and the cathode respectively. The cost targets and several degradation mechanisms acting on the catalyst layer have led to considerable research in this extremely important component. Various alloys of Pt such as Pt-Co, Pt-Ni, Pt-Fe, Pt-V, Pt-Mn and Pt-Cr have shown promising results [39Pharkya, P.; Alfantazi, A.; Farhat, Z. Fabrication using high-energy ballmilling technique and characterization of Pt–Co electrocatalysts for OR in polymer electrolyte fuel cells. Fuel. Cell. Sci. Technol., 2005, 2(3), 171-178.]. Another component that has considerable influence on the cost, durability and the performance of the catalyst layer is the catalyst support. A number of novel supports have recently been developed that aim to not only meet cost targets but also improve the activity and the durability of the catalyst layers. The GDL is a multi-functional component of the MEA and primarily responsible for allowing reactant gases to diffuse to the catalyst layer, while also providing electrical conduction away from the MEA to an external circuit. Research has mainly improved the mass transport and water management issues surrounding GDL’s. One concept is the dual layer GDL, where a transitional porous region is added between the bulk porous domain of the GDL and the fine porous region of the catalyst layer. The bulk porous region acts as the current collector and provides bulk/ diffusive flow to the transitional layer. The transitional region is usually between 20-50 μm thick and changes its porosity from 10-30μm in diameter to 10-100nm in diameter which substantially improves the gas distribution to the reaction sites. The layer also helps to remove excess water away by binding the nanoparticles of graphite with PTFE in an effort to remove excess water away from the reaction sites. Careful optimization is required to ensure that the membrane is suitably humidified, while also ensuring that excess water does not form in the cathode gas diffusion layer (GDL), which will create other operational issues within the fuel cell stack. While raising the operating temperature of the fuel cell will increase the reaction kinetics of both the hydrogen oxidation (HOR) and the (ORR), it risks dehydrating. This will also increase the Ohmic resistance of the cell and critically damage the membrane, thus offsetting any gains made in increasing reaction rates.

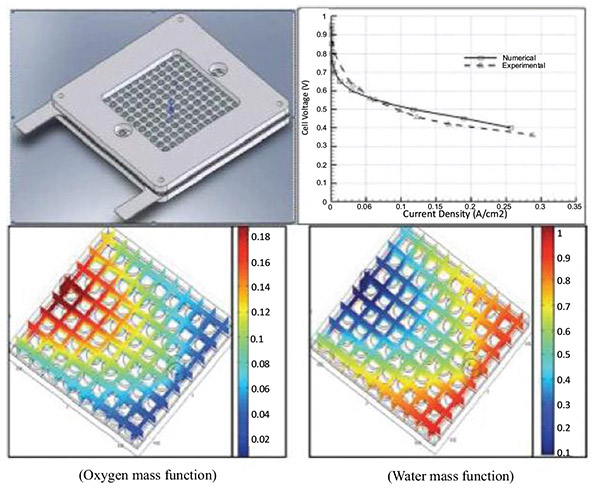

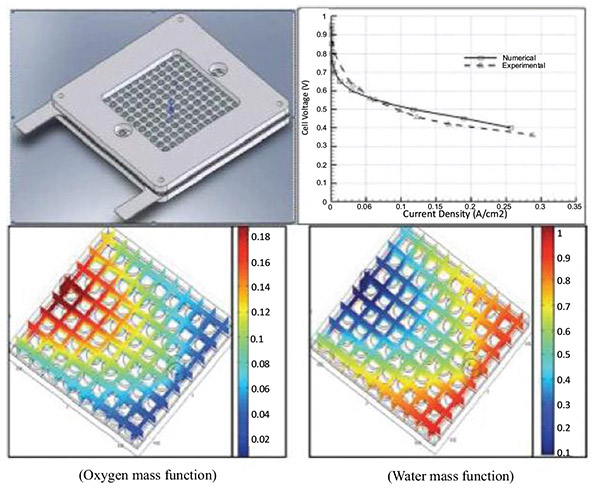

There has been limited work presented over the past decade on the design and manufacturing of new fuel cell stacks, where alternative BPP’s or changes in stack architecture have been applied in order to improve fuel cell performance, improve gravimetric and volumetric power densities while also reducing the cost of the stack. Mohamad Y. Mustafa tested a two cell stack which comprised of perforated plates as BPP and presented numerical and experimental performance results, as shown in Fig. (3 ) above. The performance was reported to be similar to that of a conventional FC [40Mohamad, Y. Design and manufacturing of a (PEMFC) proton exchange membrane fuel cell. Symposium on Innovative Materials for Processes in Energy Systems, December 2010]. Scott et al. also presented a study of novel design of fuel cell stack (Figs. 4

) above. The performance was reported to be similar to that of a conventional FC [40Mohamad, Y. Design and manufacturing of a (PEMFC) proton exchange membrane fuel cell. Symposium on Innovative Materials for Processes in Energy Systems, December 2010]. Scott et al. also presented a study of novel design of fuel cell stack (Figs. 4 and 5

and 5 ) with an aim of reducing the cost of a low temperature PEM fuel cell stack by modifying the stack architecture. The selection of the component materials was based mainly on the cost without sacrificing the performance. They also introduced the fault tolerant system.

) with an aim of reducing the cost of a low temperature PEM fuel cell stack by modifying the stack architecture. The selection of the component materials was based mainly on the cost without sacrificing the performance. They also introduced the fault tolerant system.

|

Fig. (4) Alternative design of a single Fuel cell [40Mohamad, Y. Design and manufacturing of a (PEMFC) proton exchange membrane fuel cell. Symposium on Innovative Materials for Processes in Energy Systems, December 2010]. |

|

Fig. (5) A novel Fuel cell [58]. |

At stack level, further studies are required in the area of optimization of the whole stack; for achieving better power density per unit volume and weight.

CONCLUSION

According to Fuel Cell Today, this year is the ninth year of commercialization of certain PEMFC categories. Many different sizes of PEMFC are currently in operation around the world providing electricity and heat safely and reliably. The total cost of this system is also decreasing, such that repeat orders for PEMFC is being placed by customers without the need for financial support. We believe that these trends will continue and demand for PEMFC will go from strength to strength.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The author would like to express gratitude to Mohammadia School of Engineers and Mohammed V University Rabat for supporting these research activities.

REFERENCES

| [1] | Belmonte, N.; Luetto, C.; Staulo, S.; Rizzi, P.; Baricco, M. Case Studies of Energy Storage with Fuel Cells and Batteries for Stationary and Mobile Applications. Challenges, 2017, 8(1), 9. |

| [2] | McLellan, B.; Zhang, Q.; Farzaneh, H.; Utama, N.A.; Ishihara, K.N. Resilience, sustainability and risk management: A focus on energy. Challenges, 2012, 3(2), 153-182. [http://dx.doi.org/10.3390/challe3020153] |

| [3] | Huggins, R. Energy Storage: Fundamentals, Materials and Applications., (1st ed.;. ), 2015, |

| [4] | Tenson, J.; Baby, R. Recent advances in proton exchange membrane fuel cells: A review. Int. Adv. Res. J. Sci., 2017, 4(Special Issue), 6. |

| [5] | Maizia, R.; Dib, A.; Thomas, A. Proton exchange membrane fuel cell diagnosis by spectral characterization of the electrochemical noise. J. Power Sources, 2017, 342, 553-561. [http://dx.doi.org/10.1016/j.jpowsour.2016.12.053] |

| [6] | Jourdani, M.; Mounir, H.; El Marjani, A. Temperature distribution effect on the performance of PEM Fuel cell modeling and simulation using Ansys Fluent. IRSEC’15, IEEE Conference,December 10-13 2015, Marrakech & Ouarzazate, Morocco |

| [7] | Jourdani, M.; Mounir, H.; El Marjani, A. Compilation of Factors Affecting Durability of PEMFC). IRSEC’14 IRSEC’14 IEEE Conference,, 2014.October 17-19Ouarzazate, Morocco |

| [8] | Maizia, R.; Dib, A.; Thomas, A. The Fuel Cell Industry Review. Fuel Cell Today, 2012, 21 |

| [9] | Neto, R.C.; Teixeira, J.C.; Azevedo, J.L. Thermal and electrical experimental characterisation of a 1 kW PEM fuel cell stack. J. Hydrog. Energy, 2013, 38(13), 5348-5356. [http://dx.doi.org/10.1016/j.ijhydene.2013.02.025] |

| [10] | Fuel Cells Section. 2016 |

| [11] | Tenson, Ti.; Baby, Ra. Recent Advances in Proton Exchange Membrane Fuel Cells: A Review. Int. Adv. Res. J. Sci., 2017, 4(Special Issue), 6. |

| [12] | Hiramitsu, Y.; Kobayashi, K.; Hori, M. Gas diffusion layer design focusing on the structure of the contact face with catalyst layer against water flooding in polymer electrolyte fuel cell. J. Power Sources, 2010, 95(22), 7559-7567. [http://dx.doi.org/10.1016/j.jpowsour.2010.05.067] |

| [13] | Dotelli, G.; Omati, L.; Stampino, P.; Grassini, P.; Brivio, D. Investigation of gas diffusion layer compression by electrochemical impedance spectroscopy on running polymer electrolyte membrane fuel cells. J. Power Sources, 2011, 196(21), 8955-8966. [http://dx.doi.org/10.1016/j.jpowsour.2011.01.078] |

| [14] | Hung, C.H; Chiu, C.H; Wang, S Ultra thin gas diffusion layer development for PEMFC. Int. J. Hydrogen Energy., 2012, 37(17), 12805-12812. [http://dx.doi.org/10.1016/j.ijhydene.2012.05.110] |

| [15] | Schweiss, R.; Steeb, M.; Wilde, M. Enhancement of proton exchange membrane fuel cell performance by doping micro porous layers of gas diffusion layers with multiwall carbon nanotubes.

. J. Power Sources., 2012, 220, 79-83. [http://dx.doi.org/10.1016/j.jpowsour.2012.07.078] |

| [16] | Yuka, O.; Sounai, A.; Michio, H. Prolongation of lifetime of high temperature proton exchange membrane fuel cells. J. Power Sources, 2013, 241, 87-93. [http://dx.doi.org/10.1016/j.jpowsour.2013.03.122] |

| [17] | Morgan, M.; Ravindra, D. Understanding the gas diffusion layer in PEMFCs. 1. How its structural characteristics affect diffusion and performance. J. Power Sources, 2014, 251, 269-278. [http://dx.doi.org/10.1016/j.jpowsour.2013.09.090] |

| [18] | Hirakata, S.; Hara, M.; Kakinuma, K. Investigation of the effect of a hydrophilic layer in the gas diffusion layer of a polymer electrolyte membrane fuel cell on the cell performance and cold start behavior. Electrochim. Acta, 2014, 120, 240-247. [http://dx.doi.org/10.1016/j.electacta.2013.12.050] |

| [19] | Kong, I.; Choi, J.; Kim, S.; Lee, E.; Kim, M. Experimental study on the selfhumidification effect in proton exchange membrane fuel cells containing double gas diffusion backing layer. Appl. Energy, 2015, 145, 345-353. [http://dx.doi.org/10.1016/j.apenergy.2015.02.027] |

| [20] | Zhang, Xu.; Guo, L.; Hongtan, L. Recovery mechanisms in proton exchange membrane fuel cells after accelerated stress tests. J. Power Sources, 2015, 296, 327-334. [http://dx.doi.org/10.1016/j.jpowsour.2015.07.063] |

| [21] | Kong, I.; Jung, A.; Kim, B.; Baik, K.; Kim, M. Experimental study on the start-up with dry gases from normal cell temperatures in self-humidified proton exchange membrane fuel cells. Energy, 2015, 93, 57-66. [http://dx.doi.org/10.1016/j.energy.2015.09.014] |

| [22] | Banerjee, R.; Hinebaugh, J.; Liu, H.; Yip, R.; Ge, N.; Bazylak, A. Heterogeneous porosity distributions of polymer electrolyte membrane fuel cell gas diffusion layer materials with rib-channel compression. Int. J. Hydrogen Energy, 2016, 41(33), 14885-14896. |

| [23] | Zenyuk, V.; Parkinson, Y.; Connolly, G.; Weber, Z. Gas-diffusion-layer structural properties under compression via X-ray tomography. J. Power Sources, 2016, 328, 364-376. [http://dx.doi.org/10.1016/j.jpowsour.2016.08.020] |

| [24] | Suzuki, T.; Tanaka, H.; Hayase, M.; Tsushima, S.; Hirai, S. Investigation of porous structure formation of catalyst layers for proton exchange membrane fuel cells and their effect on cell performance. Int. J. Hydrog. Energy, 2016, 41(44), 20326-20335. |

| [25] | Huang, Yu.; Cheng, Ch.; Wang, Xi.; Jang, Ji. Effects of porosity gradient in gas diffusion layers on performance of proton exchange membrane fuel cells. Energy, 2010, 35(12), 4786-4794. [http://dx.doi.org/10.1016/j.energy.2010.09.011] |

| [26] | Zhu, F. Fractal geometry model for through-plane liquid water permeability of fibrous porous carbon cloth gas diffusion layers. J. Power Sources, 2013, 243, 887-890. [http://dx.doi.org/10.1016/j.jpowsour.2013.06.079] |

| [27] | Shou, D.; Fan, J.; Ding, F. Effective diffusivity of gas diffusion layer in proton exchange membrane fuel cells. J. Power Sources, 2013, 225, 179-186. [http://dx.doi.org/10.1016/j.jpowsour.2012.10.039] |

| [28] | Kang, T.; Kim, M.; Kim, J.; Jun, Y. Numerical modeling of the degradation rate for membrane electrode assemblies in high temperature proton exchange membrane fuel cells and analyzing operational effects of the degradation. Int. J. Hydrogen Energy, 2015, 40(15), 5444-5455. |

| [29] | Straubhaar, B.; Pauchet, J.; Prat, M. Modelling of condensation in gas diffusion layers of proton exchange membrane fuel cells. Int. J. Heat Mass Transfer, 2015, 102, 891-901. [http://dx.doi.org/10.1016/j.ijheatmasstransfer.2016.06.078] |

| [30] | Nishiyama, E.; Murahashi, T. Water transport characteristics in the gas diffusion media of PEMFC – Role of the microporous layer. J. Power Sources, 2011, 196(4), 1847-1854. [http://dx.doi.org/10.1016/j.jpowsour.2010.09.055] |

| [31] | Tamayol, A.; McGregor, F.; Bahrami, M. Single phase through-plane permeability of carbon paper gas diffusion layers. J. Power Sources, 2014, 204, 94-99. |

| [32] | Zhang, Y.; Verma, A.; Pitchumani, R. Optimum design of polymer electrolyte membrane fuel cell with graded porosity gas diffusion layer. Int. J. Hydrogen Energy, 2016, 41(20), 8412-8426. [http://dx.doi.org/10.1016/j.apenergy.2016.05.057] |

| [33] | Kong, I.; Jung, A.; Kim, M. Investigations on the double gas diffusion backing layer for performance improvement of self- humidified proton

exchange membrane fuel cells.

Appl. Energy, 2016, 176, 149-156. [http://dx.doi.org/10.1016/j.apenergy.2016.05.057] |

| [34] | Tanaka, S.; Bradfield, W. Numerical and experimentally study of the effects of the electrical resistance and diffusivity under clamping pressure on the performance of a metallic gas-diffusion layer in polymer electrolyte fuel cells J. Power Sources., 2016, 330, 273-284. [http://dx.doi.org/10.1016/j.apenergy.2010.09.030] |

| [35] | Wang, Y.; Chen, S.; Chen, S.; Mishler, J.; Cho, S. A review of polymer electrolyte membrane fuel cells: Technology, applications and needs on fundamental research. Appl. Energy, 2011, 88(4), 981-1007. [http://dx.doi.org/10.1016/j.apenergy.2010.09.030] |

| [36] | Linfa, P.; Peiyun, Yi.; Xinmin, Lai Design and manufacturing of stainless steel bipolar plates for proton exchange membrane fuel cells. Int. j. hydrog. Energy., 2014, 39(36), 21127-21153. |

| [37] | Wang, Y.; Leung, D.; JinXuan, H. Wang A review on unitized regenerative fuel cell technologies, part-A: Unitized regenerative proton

exchange membrane fuel cells. Renew. Sustain. Energy Rev., 2016, 65, 961-977. [http://dx.doi.org/10.1016/j.rser.2016.07.046] |

| [38] | David, L.; Duleep, K.G. Status and outlook for the U.S. non-automotive fuel cell industry: Impacts of government policies and assessment of future opportunities., 2011. |

| [39] | Pharkya, P.; Alfantazi, A.; Farhat, Z. Fabrication using high-energy ballmilling technique and characterization of Pt–Co electrocatalysts for OR in polymer electrolyte fuel cells. Fuel. Cell. Sci. Technol., 2005, 2(3), 171-178. |

| [40] | Mohamad, Y. Design and manufacturing of a (PEMFC) proton exchange membrane fuel cell. Symposium on Innovative Materials for Processes in Energy Systems, December 2010 |