- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Open Waste Management Journal

(Discontinued)

ISSN: 1876-4002 ― Volume 13, 2020

Exergetic Analysis of Bioethanol Production from Tunisian Waste Dates

Wahada Zeineb1, *, Khila Zouhour1, Louhichi Boulbaba2, Boukchina Rachid1, Hajjaji Noureddine1

Abstract

Objective:

This study aims at contributing to the area of sustainable bioethanol production system development. The main objective of this study is to thermodynamically evaluate a bioethanol production process from waste dates.

Methods & Materials:

To this end, several chemical engineering assessment tools have been simultaneously applied. These tools simulate the bioethanol production process using the SuperPro software in order to determine all the materials and energy exchanges. An exergy analysis is also carried out, based on the first and second laws of thermodynamics, in order to locate thermodynamic imperfections in the process.

Results:

The results obtained show that approximately 60% of the exergy fed to the process is recovered in the useful products (bioethanol and exhausted pulp used as feedstuff). The overall exergy destroyed in the process considered is about 377 kW which represents 7% of the exergy reaching the process. The distillation section, the most energy-intensive stage, constitutes the main contributor of exergy destruction, followed by the fermentation reactor with contributions of 47% and 33%, respectively.

Article Information

Identifiers and Pagination:

Year: 2018Volume: 11

First Page: 19

Last Page: 32

Publisher Id: TOWMJ-11-19

DOI: 10.2174/1876400201811010019

Article History:

Received Date: 1/5/2018Revision Received Date: 4/8/2018

Acceptance Date: 15/8/2018

Electronic publication date: 31/08/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this author at the Unité de Recherche Catalyse et Matériaux pour l'Environnement et les Procédés URCMEP (UR11ES85), Ecole Nationale d’Ingénieurs de Gabès, Université de Gabès, Rue Omar Ibn Alkhattab 6029 Gabès, Tunisia; Tel: +216 55 622 668; Fax: +216 75 29 00 41; E-mail: zeinebwahada93@gmail.com

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 1-5-2018 |

Original Manuscript | Exergetic Analysis of Bioethanol Production from Tunisian Waste Dates | |

1. INTRODUCTION

Anthropogenic activities exert distressing pressure on natural resources. In fact, the high fossil fuel consumption is confronted with several problems, including the limitation of natural resources and greenhouse gas GHG emissions (CO2, CH4 and N2O). This alarming situation is marked by global warming, loss of biodiversity and depletion of resources. Thus, the energy transition towards renewable energy seems an emergency in the last decades. Several sources of renewable energies have already been topics of research works such as wind, solar, hydraulic, geothermal, biomass, etc. Currently, biomass is becoming increasingly important in research of renewable energies field. It can be converted into high-energy products, mainly through thermo-chemical routes with or without chemical catalysts such as combustion, gasification and pyrolysis [1C.I.A. Ferreira, V. Calisto, E.M. Cuerda-Correa, M. Otero, H. Nadais, and V.I. Esteves, "Comparative valorisation of agricultural and industrial biowastes by combustion and pyrolysis", Bioresour. Technol., vol. 218, pp. 918-925.

[http://dx.doi.org/10.1016/j.biortech.2016.07.047] [PMID: 27441829] ], and biochemical processes using enzymes and / or microorganisms such as anaerobic digestion for the production of biomethane [2R. Posmanik, R.A. Labatut, A.H. Kim, J.G. Usack, J.W. Tester, and L.T. Angenent, "Coupling hydrothermal liquefaction and anaerobic digestion for energy valorization from model biomass feedstocks", Bioresour. Technol., vol. 233, pp. 134-143.

[http://dx.doi.org/10.1016/j.biortech.2017.02.095] [PMID: 28267660] ], alcoholic fermentation for the production of bioethanol [3Y. Lin, and S. Tanaka, "Ethanol fermentation from biomass resources: Current state and prospects", Appl. Microbiol. Biotechnol., vol. 69, no. 6, pp. 627-642.

[http://dx.doi.org/10.1007/s00253-005-0229-x] [PMID: 16331454] ],

etc. Bioethanol is considered as an important contributor to possible solutions to our sustainable fuel needs [4H. Von, "Blottnitz, M.A. Curran, “A review of assessments conducted on bio-ethanol as a transportation fuel from a net energy, greenhouse gas, and environmental life cycle perspective", J. Clean. Prod., vol. 15, no. 7, pp. 607-619.

[http://dx.doi.org/10.1016/j.jclepro.2006.03.002] ]. It burns cleaner than gasoline, producing less CO, CO2 and NOx emissions [5A.A. Kiss, "Separative reactors for integrated production of bioethanol and biodiesel", Comput. Chem. Eng., vol. 34, no. 5, pp. 812-820.

[http://dx.doi.org/10.1016/j.compchemeng.2009.09.005] ]. However, bioethanol derived from maize and sugar cane, classified as first-generation bioethanol, is facing an intense debate “food versus fuel” [6S. Soam, M. Kapoor, R. Kumar, P. Borjesson, R.P. Gupta, and D.K. Tuli, "Global warming potential and energy analysis of second generation ethanol production from rice straw in India", Appl. Energy, vol. 184, pp. 353-364.

[http://dx.doi.org/10.1016/j.apenergy.2016.10.034] ]. Therefore, in order to avoid competition with agro-food chains, it is necessary to use non-food material such as agricultural wastes in view of their abundance and their renewable characteristics.

Tunisia is considered to be one of the major dates producing countries in the world [7W. Kchaou, F. Abbès, H. Attia, and S. Besbes, "In Vitro antioxidant activities of three selected dates from tunisia (Phoenix dactylifera L.)", J. Chem., p. 367681.]. The production of dates is estimated to be about 195,000 tones in 2013 [8W. Kchaou, F. Abbès, R.B. Mansour, C. Blecker, H. Attia, and S. Besbes, "Phenolic profile, antibacterial and cytotoxic properties of second grade date extract from Tunisian cultivars (Phoenix dactylifera L.)". Food Chem., vol. 194, pp. 1048-1055, 2016.

[http://dx.doi.org/10.1016/j.foodchem.2015.08.120] [PMID: 26471652] ]. Approximately, 30% of the total production is generally discarded due to inadequate texture (too soft or too hard), fungal contamination, or insect infestation [9S. Besbes, L. Drira, C. Blecker, C. Deroanne, and H. Attia, "Adding value to hard date (Phoenix dactylifera L.): Compositional, functional and sensory characteristics of date jam", Food Chem., vol. 112, no. 2, pp. 406-411, 2009.

[http://dx.doi.org/10.1016/j.foodchem.2008.05.093] ]. Date wastes are generally used as feed for livestock or rejected posing environmental problems. The use of this waste for the production of bioethanol could be a strategic solution for its abundance and high-sugar content. The date is composed of a flesh and a hard seed representing approximately (10-15%) of the total weight of the date [10R.G. Yousuf, and J.B. Winterburn, "Date seed characterisation, substrate extraction and process modelling for the production of polyhydroxybutyrate by Cupriavidus necator", Bioresour. Technol., vol. 222, pp. 242-251.

[http://dx.doi.org/10.1016/j.biortech.2016.09.107] [PMID: 27721098] ]. The flesh is composed of sugar-rich food fiber about 72.8% (sucrose, glucose, and fructose), mineral salts (potassium, phosphorus, magnesium, calcium, etc.) and proteins [11M. Elleuch, S. Besbes, O. Roiseux, C. Blecker, C. Deroanne, N.E. Drira, and H. Attia, "Date flesh: Chemical composition and characteristics of the dietary fibre", Food Chem., vol. 111, no. 3, pp. 676-682.

[http://dx.doi.org/10.1016/j.foodchem.2008.04.036] ]. Waste dates are considered a better non-edible alternative source for alcoholic fermentation [12M. Chandrasekaran, and A.H. Bahkali, "Valorization of date palm (Phoenix dactylifera) fruit processing by-products and wastes using bioprocess technology - Review", Saudi J. Biol. Sci., vol. 20, no. 2, pp. 105-120, 2013.

[http://dx.doi.org/10.1016/j.sjbs.2012.12.004] [PMID: 23961227] ]. For this reason, several studies have been conducted to produce bioethanol from waste dates. B. Louhichi et al. [13B. Louhichi, J. Belgaib, H. Benamor, and N. Hajji, "Production of Bioethnol from three varieties of dates", Renew. Energy, vol. 51, pp. 170-174.

[http://dx.doi.org/10.1016/j.renene.2012.07.028] ] carried out a synthesis study of bioethanol from three secondary varieties of dates (Kunta, Eguoua and Bouhatem) in the Gabes-Tunisia region. The alcoholic fermentation was investigated under sugar concentration near to 200 g L-1 at 30°C and natural pH. The results obtained showed that all the varieties tested allow producing ethanol with a mass yield (mass of ethanol / initial mass of sugar) equal to 11%. S. Chniti et al. [14S. Chniti, H. Djelal, M. Hassouna, and A. Amrane, Residue of dates from the food industry as a new cheap feedstock for ethanol production, .] evaluated the bioethanol production capacity of the three yeasts, Saccharomyces cerevisiae, Zygosaccharomyces rouxii and Candida pelliculosa, from waste dates. The best result is retained with the strain S. cerevisiae with an initial concentration of 174 g L-1 and with 38% mass yield of ethanol.

Currently, exergy analysis is used to evaluate the performance of different systems and to improve their efficiencies [15R. Saidur, "G. BoroumandJazi, S. Mekhilef, H.A Mohammed, “A review on exergy analysis of biomass based fuels", Renew. Sustain. Energy Rev., vol. 16, no. 2, pp. 1217-1222.

[http://dx.doi.org/10.1016/j.rser.2011.07.076] ]. The link between the exergy analysis and the sustainability shows that reduction of the loss of energy quality (exergy) leads to ensure sustainability of energy use [15R. Saidur, "G. BoroumandJazi, S. Mekhilef, H.A Mohammed, “A review on exergy analysis of biomass based fuels", Renew. Sustain. Energy Rev., vol. 16, no. 2, pp. 1217-1222.

[http://dx.doi.org/10.1016/j.rser.2011.07.076] ]. Exergy analysis is based on both the first and second laws of thermodynamics able to locate the imperfections of a system and identifying their causes [16R. Palacios-Bereche, K.J. Mosqueira-Salazar, M. Modest, A.V. Ensinas, S.A. Nebra, L.M. Serra, and M. Angel Lozano, "Exergetic analysis of the integrated first- and second-generation ethanol production from sugarcane", Energy, vol. 62, pp. 46-61.

[http://dx.doi.org/10.1016/j.energy.2013.05.010] ]. Exergy is a relevant tool in terms of energy efficiency, thus contributing significantly to improving energy efficiency and thus increasing environmental efficiency (evaluating our consumption and production lead to less pollution). From a thermodynamic point of view, exergy is defined as the maximum amount of work that can be produced by a flow of material, heat or work in interaction with a reference environment (characterized by temperature T0 and pressure P0 and a composition of reference state) [17S.S. Hosseini, M. Aghbashlo, M. Tabatabaei, H. Younesi, and G. Najafpour, "Exergy analysis of biohydrogen production from various carbon sources via anaerobic photosynthetic bacteria (Rhodospirillum rubrum)", Energy, vol. 93, pp. 730-739.

[http://dx.doi.org/10.1016/j.energy.2015.09.060] ]. Many recent bioethanol studies have focused on exergy analysis to assess the performance and sustainability of the bioethanol production process [16R. Palacios-Bereche, K.J. Mosqueira-Salazar, M. Modest, A.V. Ensinas, S.A. Nebra, L.M. Serra, and M. Angel Lozano, "Exergetic analysis of the integrated first- and second-generation ethanol production from sugarcane", Energy, vol. 62, pp. 46-61.

[http://dx.doi.org/10.1016/j.energy.2013.05.010] , 18C. Ofori-Boateng, and K.T. Lee, "Comparative thermodynamic sustainability assessment of lignocellulosic pretreatment methods for bioethanol production via exergy analysis", Chem. Eng. J., vol. 228, pp. 162-171.

[http://dx.doi.org/10.1016/j.cej.2013.04.082] -20K. Ojeda, E. Sánchez, and V. Kafarov, "Sustainable ethanol production from lignocellulosic biomass. Application of exergy analysis", Energy, vol. 36, no. 4, pp. 2119-2128.

[http://dx.doi.org/10.1016/j.energy.2010.08.017] ].

The main objective of this study is to evaluate the energy performance of the bioethanol production process from waste dates via an exergy analysis. This analysis serves as a guide to improving efficiency by focusing on exergy destroyed during key stages of bioethanol production in order to identify areas of imperfection and to understand the sources of thermodynamics imperfections

2. MATERIALS AND METHODS

2.1. Characterization of Waste Dates

Waste dates, considered in this work, comes mainly from the two varieties of dates: ” Allig” and ” Deglet Nour” produced in the desert regions of southern Tunisia. These two Tunisian varieties constitute the large part of the production (about 195,000 tons in 2013 [8W. Kchaou, F. Abbès, R.B. Mansour, C. Blecker, H. Attia, and S. Besbes, "Phenolic profile, antibacterial and cytotoxic properties of second grade date extract from Tunisian cultivars (Phoenix dactylifera L.)". Food Chem., vol. 194, pp. 1048-1055, 2016.

[http://dx.doi.org/10.1016/j.foodchem.2015.08.120] [PMID: 26471652] ]). A significant fraction of production is lost during picking, packaging and storage [21M. Masmoudi, S. Besbes, M. Chaabouni, C. Robert, M. Paquot, C. Blecker, and H. Attia, "Optimization of pectin extraction from lemon by-product with acidified date juice using response surface methodology", Carbohydr. Polym., vol. 74, no. 2, pp. 185-192.

[http://dx.doi.org/10.1016/j.carbpol.2008.02.003] ]. The date is composed of soft, edible flesh and a hard seed, representing approximately (10-15%) of the total date weight [10R.G. Yousuf, and J.B. Winterburn, "Date seed characterisation, substrate extraction and process modelling for the production of polyhydroxybutyrate by Cupriavidus necator", Bioresour. Technol., vol. 222, pp. 242-251.

[http://dx.doi.org/10.1016/j.biortech.2016.09.107] [PMID: 27721098] ]. The flesh consists of sugar-rich food fiber (sucrose, glucose, and fructose), mineral salts (potassium, phosphorus, magnesium, calcium, etc.) and proteins. Table 1 shows the average chemical composition of the dates considered [11M. Elleuch, S. Besbes, O. Roiseux, C. Blecker, C. Deroanne, N.E. Drira, and H. Attia, "Date flesh: Chemical composition and characteristics of the dietary fibre", Food Chem., vol. 111, no. 3, pp. 676-682.

[http://dx.doi.org/10.1016/j.foodchem.2008.04.036] ]. These data are used subsequently to study bioethanol production process by alcoholic fermentation of waste dates.

Chemical composition of date fleshes [11M. Elleuch, S. Besbes, O. Roiseux, C. Blecker, C. Deroanne, N.E. Drira, and H. Attia, "Date flesh: Chemical composition and characteristics of the dietary fibre", Food Chem., vol. 111, no. 3, pp. 676-682.

[http://dx.doi.org/10.1016/j.foodchem.2008.04.036] ].

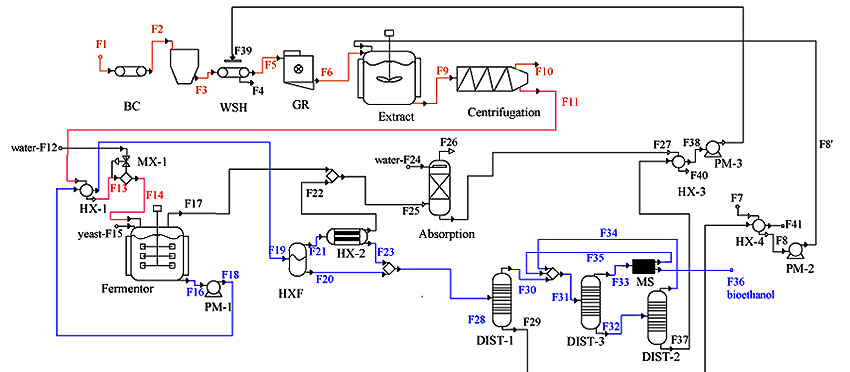

2.2. Simulation of the Process

The bioethanol production process from waste dates includes three main sections: (1) pretreatment, (2) fermentation and (3) purification. The purification section was adopted from a published article [22I. Barrera, M.A. Amezcua-Allieri, L. Estupi˜nan, T. Martínez, and J. Aburto, "Technical and economical evaluation of bioethanol production from lignocellulosic residues in Mexico: Case of sugarcane and blue agave bagasses", Chem. Eng. Res. Des., vol. 107, pp. 91-101.

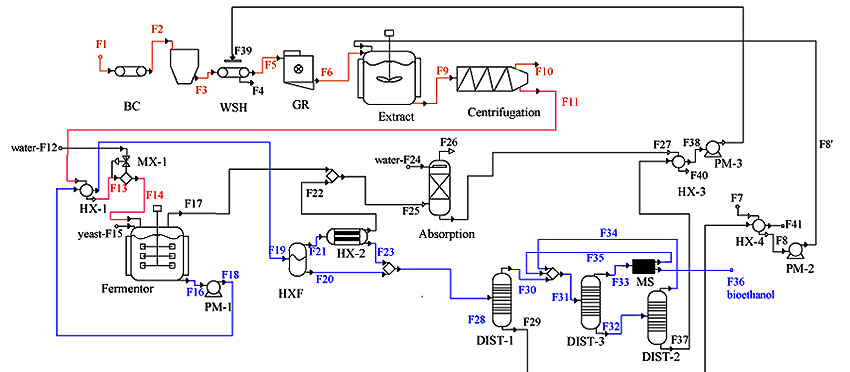

[http://dx.doi.org/10.1016/j.cherd.2015.10.015] ] dealing with the production of bioethanol from sugarcanes and blue agaves. To describe the process and calculate the material and energy exchanges, the bioethanol plant was simulated by SuperPro Designer® 8.5 (Intelligen, Inc.). The flowsheet is given in Fig. (1 ). The simulation results are subsequently used to compute all exergy forms exchanged in the process.

). The simulation results are subsequently used to compute all exergy forms exchanged in the process.

|

Fig. (1) Detailed flow diagram of bioethanol production process from waste dates. |

2.2.1. Pretreatment

The pretreatment section is devoted for sugar extraction, using various equipments. A conveyor belt (BC) is used as a mechanical supplier to feed the process (F1). Dates are then washed (F5) and grinded (F6) to make them suitable for the sugar extraction stage respecting optimums conditions described in B.louhichi et al. [13B. Louhichi, J. Belgaib, H. Benamor, and N. Hajji, "Production of Bioethnol from three varieties of dates", Renew. Energy, vol. 51, pp. 170-174.

[http://dx.doi.org/10.1016/j.renene.2012.07.028] ]. To separate sugar-rich juice (F11) from the solid phase (F10), a following centrifugation operation is carried out. The exhausted pulp (F10) is considered a byproduct which it could be used as feed for livestock.

2.2.2. Fermentation

The operating conditions in the fermentor are fixed on the basis of results published by B. Loufichi et al. [13B. Louhichi, J. Belgaib, H. Benamor, and N. Hajji, "Production of Bioethnol from three varieties of dates", Renew. Energy, vol. 51, pp. 170-174.

[http://dx.doi.org/10.1016/j.renene.2012.07.028] ]. The reactions extents are closely related to the yeast strain retained for this study (S.cerevisiae FRCH strain [23J. Tronchoni, A. Gamero, F.N. Arroyo-López, E. Barrio, and A. Querol, "Differences in the glucose and fructose consumption profiles in diverse Saccharomyces wine species and their hybrids during grape juice fermentation", Int. J. Food Microbiol., vol. 134, no. 3, pp. 237-243.

[http://dx.doi.org/10.1016/j.ijfoodmicro.2009.07.004] [PMID: 19632733] , 24F.W. Bai, W.A. Anderson, and M. Moo-Young, "Ethanol fermentation technologies from sugar and starch feedstocks", Biotechnol. Adv., vol. 26, no. 1, pp. 89-105.

[http://dx.doi.org/10.1016/j.biotechadv.2007.09.002] [PMID: 17964107] ]). The main reactions involved in the fermentor are summarized in Table 2. An adjustable flow mixer (MX-1) is used to adjust the stream (F14) to the desirable concentration of sugars.

2.3. Basis of the Exergy Analysis

2.3.1. Different forms of Exergy

In this paper, three forms of exergy are considered: exergy associated with heat transfer, exergy associated with mechanical work and exergy associated with a steady stream of matter. The environmental temperature and pressure used in this work are respectively 298.15 K and 1 atm.

a. Exergy associated with heat and work transfer

The exergy associated with a heat flow is expressed as follows (Eq.1) [25T.J. Kotas, The exergy method of thermal plant analysis, .].

|

(1) |

Where T0 is the reference temperature (298.15 K), T is the temperature at which the heattransfer occurs, Q is amount of heat transferred.

- The exergy associated with the transfer of mechanical work (Eq.2).

|

(2) |

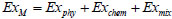

b. Exergy associated to material stream This step consists in determining the exergy associated to material stream (ExM) that includes five terms, namely physical exergy (Exphy), chemical exergy (Exchem), the exergy of mixing (Exmix), the kinetic exergy (Exkin) and the potential exergy (Expot). Only the chemical, physical and mixtures exergy are calculated in the present study. The variations of the kinetic and potential exergies are often neglected in the expression of matter [16R. Palacios-Bereche, K.J. Mosqueira-Salazar, M. Modest, A.V. Ensinas, S.A. Nebra, L.M. Serra, and M. Angel Lozano, "Exergetic analysis of the integrated first- and second-generation ethanol production from sugarcane", Energy, vol. 62, pp. 46-61.

[http://dx.doi.org/10.1016/j.energy.2013.05.010] , 18C. Ofori-Boateng, and K.T. Lee, "Comparative thermodynamic sustainability assessment of lignocellulosic pretreatment methods for bioethanol production via exergy analysis", Chem. Eng. J., vol. 228, pp. 162-171.

[http://dx.doi.org/10.1016/j.cej.2013.04.082] ].

|

(3) |

The exergy associated with the material flow is computed accordingly to the methods described by A.P. Hinderink et al. [26A.P. Hinderink, F.P.J.M. Kerkhot, and A.B.K. Lie, "J. DE Swaan Arons, H.J Van Der Kooi, “Exergy analysis with a flowsheeting simulator–I Theory; calculating exergies of material streams", Chem. Eng. Sci., vol. 51, no. 20, pp. 4693-4700.

[http://dx.doi.org/10.1016/0009-2509(96)00220-5] ] frequently adopted in research topics dealing with exergetic analysis [27A. Modarresi, P. Kravanja, and A. Friedl, "Pinch and exergy analysis of lignocellulosic ethanol, biomethane, heat and power production from straw", Appl. Therm. Eng., vol. 43, pp. 20-28.

[http://dx.doi.org/10.1016/j.applthermaleng.2012.01.026] , 28A.C.B. Araújo, L.G.S. Vasconcelos, M.F. Fossy, and R.P. Brito, "Exergetic and economic analysis of an industrial distillation column", Braz. J. Chem. Eng., vol. 24, no. 03, pp. 461-469.

[http://dx.doi.org/10.1590/S0104-66322007000300015] ].

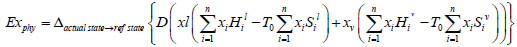

The physical exergy (Exphy) is the maximum amount of work that can be retrieved when a material flow is brought from its initial state (T, P) to the state of the defined environment by (T0, P0) by a process involving only a thermal interaction with the environment [25T.J. Kotas, The exergy method of thermal plant analysis, .]. This component is given by A. P. Hinderink et al. [26A.P. Hinderink, F.P.J.M. Kerkhot, and A.B.K. Lie, "J. DE Swaan Arons, H.J Van Der Kooi, “Exergy analysis with a flowsheeting simulator–I Theory; calculating exergies of material streams", Chem. Eng. Sci., vol. 51, no. 20, pp. 4693-4700.

[http://dx.doi.org/10.1016/0009-2509(96)00220-5] ] (Eq.4).

|

(4) |

where n is the number of chemical species in a flow of material, D is the mass flow, xl and xv are the mass fraction of liquid and vapor, respectively, in the flow of material, xi and yi are respectively the mass fraction of species i in the liquid and vapor phases steam, Hi and Si are respectively mass enthalpy and entropy of the pure component i. Indices l and v refer respectively to the liquid and vapor phases.

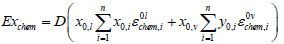

-The chemical exergy (Exchem) is the maximum work that can be recovered when the substance under consideration is brought from the environment, defined by the parameters T0 and P0, to the dead state by a process involving only heat transfer and material exchange with the environment (Kotas, 1995) [25T.J. Kotas, The exergy method of thermal plant analysis, .]. The chemical exergy is given by [26A.P. Hinderink, F.P.J.M. Kerkhot, and A.B.K. Lie, "J. DE Swaan Arons, H.J Van Der Kooi, “Exergy analysis with a flowsheeting simulator–I Theory; calculating exergies of material streams", Chem. Eng. Sci., vol. 51, no. 20, pp. 4693-4700.

[http://dx.doi.org/10.1016/0009-2509(96)00220-5] ] A.P. Hinderink and et al. (Eq.5).

|

(5) |

Where εchem,i0l, εchem,i0v are respectively the standard chemical exergy of the species (i) in liquid and vapor phase, determined from Kotas [25T.J. Kotas, The exergy method of thermal plant analysis, .]. Chemical exergies process components are evaluated using the composition of the reference environment defined by Kotas [25T.J. Kotas, The exergy method of thermal plant analysis, .]. The mixing exergy (Exmix) always has a negative value (Eq.6) [26A.P. Hinderink, F.P.J.M. Kerkhot, and A.B.K. Lie, "J. DE Swaan Arons, H.J Van Der Kooi, “Exergy analysis with a flowsheeting simulator–I Theory; calculating exergies of material streams", Chem. Eng. Sci., vol. 51, no. 20, pp. 4693-4700.

[http://dx.doi.org/10.1016/0009-2509(96)00220-5] ].

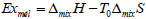

|

(6) |

Where

|

(7) |

|

(8) |

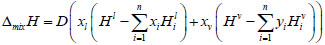

2.3.2. Exergetic Evaluation

To establish an exergy balance, we consider an open system operating in steady state. This balance consists on coupling an enthalpic and entropic balance that highlighting the term of destroyed exergy (Exdestroyed). The arrangement of material, enthalpy and entropy balances leads to Eq.(9) [25T.J. Kotas, The exergy method of thermal plant analysis, .].

|

(9) |

This expression, known as the exergy balance, includes four terms:

1: Specific exergy associated with matter (ExM = Exphy + Exchem + Exmix).

2: Exergy associated with heat transfer.

3: Exergy associated with mechanical work exchange.

4: Term corresponding to the creation of entropy due to the different irreversibility of the system, it is exergy destroyed.

With:

Din: Mass flow of material at system inlet.

Dout: Mass flow of material at the system outlet.

Qk: The quantity of heat exchanged by the system at a temperature Tk.

Wk: Non-thermal energy (mechanical, electrical ...) received by the system.

To compute the destroyed exergy, the detailed method is considered which provides the contribution of each equipment (e.g. distillation column) to the total exergy destroyed. More details about the calculations are provided in supplementary materials.

3. RESULTS AND INTERPERTATIONS

3.1. Process Design and Simulation

The simulation results show the thermal and mechanical powers exchanged at the various equipments (Table 3) and the characteristics of the different material flows (flow, temperature, pressure, composition, enthalpy) (Table 4). The main operating conditions needed in the process simulation are retrieved from experimental study [13B. Louhichi, J. Belgaib, H. Benamor, and N. Hajji, "Production of Bioethnol from three varieties of dates", Renew. Energy, vol. 51, pp. 170-174.

[http://dx.doi.org/10.1016/j.renene.2012.07.028] ] to match as possible real operating unit and to get valuable results. The novelty of this work is the relevant application of waste dates in the field of bioethanol. However, conduct a rational comparative analysis between the studied system and real ones which involve the same transformations steps is a big challenge.

3.2. Exergy Analysis Results

The different forms of exergy exchanged in the process (matter, work, heat) are gathered in Tables 5 and 6.

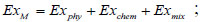

Aspen PlusTM is employed in order to estimate the thermodynamic properties (enthalpy and entropy) of each stream. The hypothesis considered in this step is to assimilate all organic compounds that constitute date fleshes to dextrose (sugar predefined in AspenPlus database), thus dates are modulated as (95% dextrose and 5% water). To calculate the exergy associated to the stream material F1 (waste dates entering the system) we proceed as describe in the text.

|

Expky = 0 Because the flux is in environmental conditions (T=100 kPa, and T= 298.15 K).

|

Where

ε0 chem, i is the standard chemical exergy of the species (i) determined from Kotas [25T.J. Kotas, The exergy method of thermal plant analysis, .].

|

Exergy associated to different streams are listed in Table 6.

We display in Table 7 the outcomes of exergy balance carried on the main components of the process. More details about the calculations of exergy balance are provided in supplementary materials.

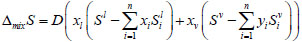

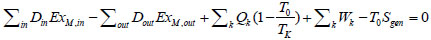

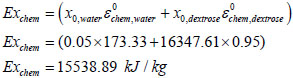

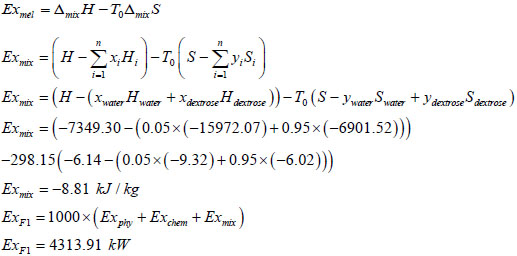

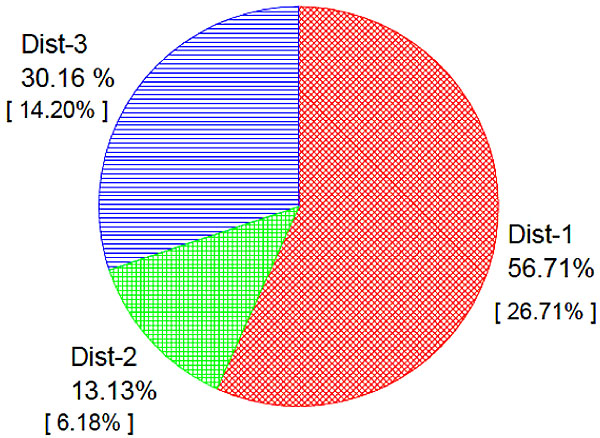

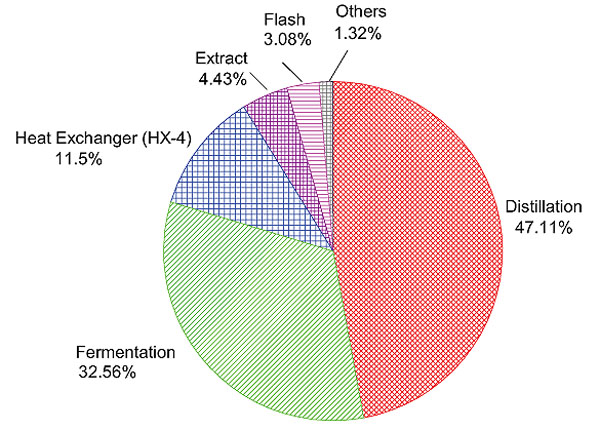

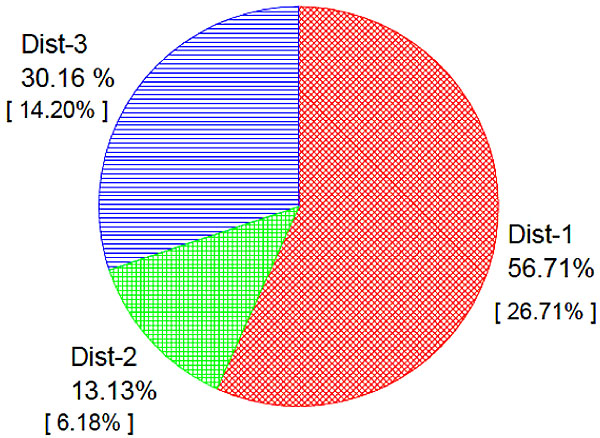

The distillation section has the most exergy destruction (Fig. 2 ) of 177.8 kW about 47% of the total exergy destruction in the bioethanol production process. According to the fractionating principles, reducing the reflux ratio, ie increasing the number of stages, could lead to a substantial reduction in the irreversibility of the column [29Z. Wei, B. Zhang, S. Wu, Q. Chen, and G. Tsatsaronis, "Energy-use analysis and evaluation of distillation systems through avoidable exergy destruction and investment costs", Energy, vol. 42, no. 1, pp. 424-433.

) of 177.8 kW about 47% of the total exergy destruction in the bioethanol production process. According to the fractionating principles, reducing the reflux ratio, ie increasing the number of stages, could lead to a substantial reduction in the irreversibility of the column [29Z. Wei, B. Zhang, S. Wu, Q. Chen, and G. Tsatsaronis, "Energy-use analysis and evaluation of distillation systems through avoidable exergy destruction and investment costs", Energy, vol. 42, no. 1, pp. 424-433.

[http://dx.doi.org/10.1016/j.energy.2012.03.026] ]. Heat exchangers (condenser and reboiler) are also a source of irreversibility in the distillation column due to the considerable temperature differences between the hot and cold streams. To see in details, the distribution of the exergy destroyed through the various distillation columns, the contribution of each column to the exergy destroyed is shown in Fig. (3 ). It is clear that the first distillation column “Dist-1” “constitutes the most zone of thermodynamic imperfection of the process. It contributes to more than half of the destroyed exergy of the distillation columns and thus accounts for 26.71% of the total exergy destruction from the process. The fermentation process contributes about 33% of the exergy destruction of the system. Its inefficiency is mainly caused by the creation of entropies during biochemical reactions and the dissipation of heat due to the exothermic nature of the reactions [30H.I. Velásquez-Arredondo, S. De Oliveira Junior, and P. Benjumea, "Exergy efficiency analysis of chemical and biochemical stages involved in liquid biofuels production processes", Energy, vol. 41, no. 1, pp. 138-145.

). It is clear that the first distillation column “Dist-1” “constitutes the most zone of thermodynamic imperfection of the process. It contributes to more than half of the destroyed exergy of the distillation columns and thus accounts for 26.71% of the total exergy destruction from the process. The fermentation process contributes about 33% of the exergy destruction of the system. Its inefficiency is mainly caused by the creation of entropies during biochemical reactions and the dissipation of heat due to the exothermic nature of the reactions [30H.I. Velásquez-Arredondo, S. De Oliveira Junior, and P. Benjumea, "Exergy efficiency analysis of chemical and biochemical stages involved in liquid biofuels production processes", Energy, vol. 41, no. 1, pp. 138-145.

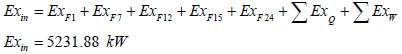

[http://dx.doi.org/10.1016/j.energy.2011.06.025] ]. The heat exchanger (HX-4) is the third contributor to the exergy destruction with about 11.5% of the exergy destroyed this is due to the temperature difference between the hot and cold flow which is around 35° C. Finally, the extraction tank also contributes to the exergy destroyed about (4.43% of the total exergy destroyed) which can be at the origin of concentration gradient during perpetual diffusion of sugars from the concentrated zones to the diluted zones. The method conducted to compute the exergy destroyed is a detailed one i.e., we focus on the exergy destroyed in each equipment to figure out its contribution to the thermodynamic imperfections. While the total exergy that entering the system is:

|

where

ExF1, ExF7, ExF12, ExF15, ExF24 are exergy associated to material streams F1, F7, F12, F15, F24 respectively. ΣExQ, ΣExw are exergy associated with heat flow and mechanical work provided to the main steps of the system. Thus the overall exergy destruction (377.54 kW) represents 7.21% of the exergy entering the system.

|

Fig. (2) Distribution of exergy destroyed in bioethanol process. |

|

Fig. (3) Contribution of each column distillation to the total exergy destroyed associated to the the distillation section [% to the total exergy destruction]. |

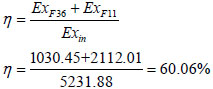

Furthermore to calculate the exergetic efficiency of the process we adopt the rational exergy efficiency which is the ratio of exergy content of useful products to the total exergy input [27A. Modarresi, P. Kravanja, and A. Friedl, "Pinch and exergy analysis of lignocellulosic ethanol, biomethane, heat and power production from straw", Appl. Therm. Eng., vol. 43, pp. 20-28.

[http://dx.doi.org/10.1016/j.applthermaleng.2012.01.026] ]. The useful products leaving the system are bioethanol (F36) and exhausted pulp used as feed for animal (F10), exergetic efficiency is computed as below

|

To the best of our knowledge exergetic analysis of bioethanol production from waste dates has not yet been carried out to measure the thermodynamic performance of such system which constitutes the novelty of this work. Exergy analysis can deal with any systems of different features and is powerful in qualitative analysis for any elements of a system. Furthermore, the exergy analysis can indicate the major cause of imperfections of a system. However, the lack of a formal procedure in using the results from an exergy analysis is one of its limitations. Therefore, the combination of two relevant methods the pinch and exergy analysis constitutes a rational basis for process modifications. Pinch or exergy analysis alone cannot fulfill the task for effective process modification, since they have their own intrinsic advantages and disadvantages. The power of pinch analysis (which is not the purpose of this work) is in showing the main features of a system on simple diagrams. Therefore, the proper combination of these two methods can brought significant benefits for process modifications, since it is essential to display the system information graphically to visualize its performance and quantitatively identify major directions for improvement [31X. Feng, and X.X. Zhu, "Combining pinch and exergy analysis for process modifications", Appl. Therm. Eng., vol. II, no. 3, pp. 249-261.

[http://dx.doi.org/10.1016/S1359-4311(96)00035-X] ].

CONCLUSION

The main objective of this study is to provide an exergetic investigation of bioethanol production system from waste dates. Several chemical engineering assessment tools have been simultaneously applied. The main outcomes of this research can be summarized in these points: - Approximately 60% of the exergy fed to the process is recovered in the useful product (bioethanol and feedstuff).

About 7% of the exergy reaching the process is destroyed due to the imperfections of the thermodynamic transformations.

The overall exergy destruction in the process is about 377.54 kW.

The greatest loss of exergy is localized in the distillation section; this is due to the mixture of the streams with unbalanced compositions and the differences in temperatures in the stages of the column.

The fermentation reactor occupies the second place in term of exergy destruction with a contribution of 33% followed by the exchanger (HX-4) 11.5%. This paper could be used as a support tools for the implantation of industrial process for bioethanol production from waste dates.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.

NOMENCLATURE

| Notation | |

| D | = total mass flow rate |

| Ex | = Exergy |

| H | = mass enthalpy |

| LHV | = lower Heating Value |

| n | = number of chemical species in the material stream |

| P | = Pressure |

| Q | = heat transferred |

| S | = mass entropy |

| T | = Temperature |

| Subscripts | |

| M | = material stream |

| mix | = mixing part |

| Q | = heat transfer |

| phy | = physical part |

| W | = mechanical work |

| chem | = chemical part |

| 0 | = reference conditions |

| Superscripts | |

| l | = liquid phase |

| v | = vapor phase |

| 0 | = pure component properties at standard conditions at T0, P0 |

| Greek letters | |

| ε | = mass standard chemical exergy |

| η | = Efficiency |

REFERENCES

| [1] | C.I.A. Ferreira, V. Calisto, E.M. Cuerda-Correa, M. Otero, H. Nadais, and V.I. Esteves, "Comparative valorisation of agricultural and industrial biowastes by combustion and pyrolysis", Bioresour. Technol., vol. 218, pp. 918-925. [http://dx.doi.org/10.1016/j.biortech.2016.07.047] [PMID: 27441829] |

| [2] | R. Posmanik, R.A. Labatut, A.H. Kim, J.G. Usack, J.W. Tester, and L.T. Angenent, "Coupling hydrothermal liquefaction and anaerobic digestion for energy valorization from model biomass feedstocks", Bioresour. Technol., vol. 233, pp. 134-143. [http://dx.doi.org/10.1016/j.biortech.2017.02.095] [PMID: 28267660] |

| [3] | Y. Lin, and S. Tanaka, "Ethanol fermentation from biomass resources: Current state and prospects", Appl. Microbiol. Biotechnol., vol. 69, no. 6, pp. 627-642. [http://dx.doi.org/10.1007/s00253-005-0229-x] [PMID: 16331454] |

| [4] | H. Von, "Blottnitz, M.A. Curran, “A review of assessments conducted on bio-ethanol as a transportation fuel from a net energy, greenhouse gas, and environmental life cycle perspective", J. Clean. Prod., vol. 15, no. 7, pp. 607-619. [http://dx.doi.org/10.1016/j.jclepro.2006.03.002] |

| [5] | A.A. Kiss, "Separative reactors for integrated production of bioethanol and biodiesel", Comput. Chem. Eng., vol. 34, no. 5, pp. 812-820. [http://dx.doi.org/10.1016/j.compchemeng.2009.09.005] |

| [6] | S. Soam, M. Kapoor, R. Kumar, P. Borjesson, R.P. Gupta, and D.K. Tuli, "Global warming potential and energy analysis of second generation ethanol production from rice straw in India", Appl. Energy, vol. 184, pp. 353-364. [http://dx.doi.org/10.1016/j.apenergy.2016.10.034] |

| [7] | W. Kchaou, F. Abbès, H. Attia, and S. Besbes, "In Vitro antioxidant activities of three selected dates from tunisia (Phoenix dactylifera L.)", J. Chem., p. 367681. |

| [8] | W. Kchaou, F. Abbès, R.B. Mansour, C. Blecker, H. Attia, and S. Besbes, "Phenolic profile, antibacterial and cytotoxic properties of second grade date extract from Tunisian cultivars (Phoenix dactylifera L.)". Food Chem., vol. 194, pp. 1048-1055, 2016. [http://dx.doi.org/10.1016/j.foodchem.2015.08.120] [PMID: 26471652] |

| [9] | S. Besbes, L. Drira, C. Blecker, C. Deroanne, and H. Attia, "Adding value to hard date (Phoenix dactylifera L.): Compositional, functional and sensory characteristics of date jam", Food Chem., vol. 112, no. 2, pp. 406-411, 2009. [http://dx.doi.org/10.1016/j.foodchem.2008.05.093] |

| [10] | R.G. Yousuf, and J.B. Winterburn, "Date seed characterisation, substrate extraction and process modelling for the production of polyhydroxybutyrate by Cupriavidus necator", Bioresour. Technol., vol. 222, pp. 242-251. [http://dx.doi.org/10.1016/j.biortech.2016.09.107] [PMID: 27721098] |

| [11] | M. Elleuch, S. Besbes, O. Roiseux, C. Blecker, C. Deroanne, N.E. Drira, and H. Attia, "Date flesh: Chemical composition and characteristics of the dietary fibre", Food Chem., vol. 111, no. 3, pp. 676-682. [http://dx.doi.org/10.1016/j.foodchem.2008.04.036] |

| [12] | M. Chandrasekaran, and A.H. Bahkali, "Valorization of date palm (Phoenix dactylifera) fruit processing by-products and wastes using bioprocess technology - Review", Saudi J. Biol. Sci., vol. 20, no. 2, pp. 105-120, 2013. [http://dx.doi.org/10.1016/j.sjbs.2012.12.004] [PMID: 23961227] |

| [13] | B. Louhichi, J. Belgaib, H. Benamor, and N. Hajji, "Production of Bioethnol from three varieties of dates", Renew. Energy, vol. 51, pp. 170-174. [http://dx.doi.org/10.1016/j.renene.2012.07.028] |

| [14] | S. Chniti, H. Djelal, M. Hassouna, and A. Amrane, Residue of dates from the food industry as a new cheap feedstock for ethanol production, . |

| [15] | R. Saidur, "G. BoroumandJazi, S. Mekhilef, H.A Mohammed, “A review on exergy analysis of biomass based fuels", Renew. Sustain. Energy Rev., vol. 16, no. 2, pp. 1217-1222. [http://dx.doi.org/10.1016/j.rser.2011.07.076] |

| [16] | R. Palacios-Bereche, K.J. Mosqueira-Salazar, M. Modest, A.V. Ensinas, S.A. Nebra, L.M. Serra, and M. Angel Lozano, "Exergetic analysis of the integrated first- and second-generation ethanol production from sugarcane", Energy, vol. 62, pp. 46-61. [http://dx.doi.org/10.1016/j.energy.2013.05.010] |

| [17] | S.S. Hosseini, M. Aghbashlo, M. Tabatabaei, H. Younesi, and G. Najafpour, "Exergy analysis of biohydrogen production from various carbon sources via anaerobic photosynthetic bacteria (Rhodospirillum rubrum)", Energy, vol. 93, pp. 730-739. [http://dx.doi.org/10.1016/j.energy.2015.09.060] |

| [18] | C. Ofori-Boateng, and K.T. Lee, "Comparative thermodynamic sustainability assessment of lignocellulosic pretreatment methods for bioethanol production via exergy analysis", Chem. Eng. J., vol. 228, pp. 162-171. [http://dx.doi.org/10.1016/j.cej.2013.04.082] |

| [19] | "K.J Ptasinski, “Exergy analysis of thermochemical ethanol production via biomass gasification and catalytic synthesis", Energy, vol. 46, no. 1, pp. 200-210. [http://dx.doi.org/10.1016/j.energy.2012.08.036] |

| [20] | K. Ojeda, E. Sánchez, and V. Kafarov, "Sustainable ethanol production from lignocellulosic biomass. Application of exergy analysis", Energy, vol. 36, no. 4, pp. 2119-2128. [http://dx.doi.org/10.1016/j.energy.2010.08.017] |

| [21] | M. Masmoudi, S. Besbes, M. Chaabouni, C. Robert, M. Paquot, C. Blecker, and H. Attia, "Optimization of pectin extraction from lemon by-product with acidified date juice using response surface methodology", Carbohydr. Polym., vol. 74, no. 2, pp. 185-192. [http://dx.doi.org/10.1016/j.carbpol.2008.02.003] |

| [22] | I. Barrera, M.A. Amezcua-Allieri, L. Estupi˜nan, T. Martínez, and J. Aburto, "Technical and economical evaluation of bioethanol production from lignocellulosic residues in Mexico: Case of sugarcane and blue agave bagasses", Chem. Eng. Res. Des., vol. 107, pp. 91-101. [http://dx.doi.org/10.1016/j.cherd.2015.10.015] |

| [23] | J. Tronchoni, A. Gamero, F.N. Arroyo-López, E. Barrio, and A. Querol, "Differences in the glucose and fructose consumption profiles in diverse Saccharomyces wine species and their hybrids during grape juice fermentation", Int. J. Food Microbiol., vol. 134, no. 3, pp. 237-243. [http://dx.doi.org/10.1016/j.ijfoodmicro.2009.07.004] [PMID: 19632733] |

| [24] | F.W. Bai, W.A. Anderson, and M. Moo-Young, "Ethanol fermentation technologies from sugar and starch feedstocks", Biotechnol. Adv., vol. 26, no. 1, pp. 89-105. [http://dx.doi.org/10.1016/j.biotechadv.2007.09.002] [PMID: 17964107] |

| [25] | T.J. Kotas, The exergy method of thermal plant analysis, . |

| [26] | A.P. Hinderink, F.P.J.M. Kerkhot, and A.B.K. Lie, "J. DE Swaan Arons, H.J Van Der Kooi, “Exergy analysis with a flowsheeting simulator–I Theory; calculating exergies of material streams", Chem. Eng. Sci., vol. 51, no. 20, pp. 4693-4700. [http://dx.doi.org/10.1016/0009-2509(96)00220-5] |

| [27] | A. Modarresi, P. Kravanja, and A. Friedl, "Pinch and exergy analysis of lignocellulosic ethanol, biomethane, heat and power production from straw", Appl. Therm. Eng., vol. 43, pp. 20-28. [http://dx.doi.org/10.1016/j.applthermaleng.2012.01.026] |

| [28] | A.C.B. Araújo, L.G.S. Vasconcelos, M.F. Fossy, and R.P. Brito, "Exergetic and economic analysis of an industrial distillation column", Braz. J. Chem. Eng., vol. 24, no. 03, pp. 461-469. [http://dx.doi.org/10.1590/S0104-66322007000300015] |

| [29] | Z. Wei, B. Zhang, S. Wu, Q. Chen, and G. Tsatsaronis, "Energy-use analysis and evaluation of distillation systems through avoidable exergy destruction and investment costs", Energy, vol. 42, no. 1, pp. 424-433. [http://dx.doi.org/10.1016/j.energy.2012.03.026] |

| [30] | H.I. Velásquez-Arredondo, S. De Oliveira Junior, and P. Benjumea, "Exergy efficiency analysis of chemical and biochemical stages involved in liquid biofuels production processes", Energy, vol. 41, no. 1, pp. 138-145. [http://dx.doi.org/10.1016/j.energy.2011.06.025] |

| [31] | X. Feng, and X.X. Zhu, "Combining pinch and exergy analysis for process modifications", Appl. Therm. Eng., vol. II, no. 3, pp. 249-261. [http://dx.doi.org/10.1016/S1359-4311(96)00035-X] |