- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Open Food Science Journal

(Discontinued)

ISSN: 1874-2564 ― Volume 13, 2021

Moisture Sorption Behavior of Cupuassu Powder

Joseane C. P. Pombo1, Juliana R. Carmo1, Adriano L. Araújo1, Heloisa H. B. R. Medeiros1, Rosinelson S. Pena1, 2, *

Abstract

Introduction:

In this research, the hygroscopic behavior of cupuassu (Theobroma grandiflorum) powder containing 40% maltodextrin was studied via the moisture adsorption and desorption isotherms at 25°C.

Methods:

The experimental sorption data of the cupuassu powder were fitted using the Halsey, Henderson, Oswin, GAB and Peleg models. In addition, the powder morphology was assessed using scanning electron microscopy.

Results:

Moisture sorption isotherms curves showed type III behavior, typical of foods rich in soluble components, such as sugars, present in the samples. The adsorption curve indicated that the product requires greater attention when stored and handled in environments with relative humidity above 50%. The microbiological stability of the product is assured up to 11.5% moisture content.

Conclusion:

During the product storage, it is recommended to use packaging with water vapor and air impermeability, due to the presence of porous microspheres that affect the protection of the active material and facilitate the moisture gain. Among the models evaluated, the Peleg and GAB models presented good suitability on predicting the product’s sorption isotherms.

Article Information

Identifiers and Pagination:

Year: 2019Volume: 11

First Page: 66

Last Page: 73

Publisher Id: TOFSJ-11-66

DOI: 10.2174/1874256401911010066

Article History:

Received Date: 11/09/2018Revision Received Date: 12/12/2018

Acceptance Date: 18/12/2018

Electronic publication date: 31/05/2019

Collection year: 2019

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: (https://creativecommons.org/licenses/by/4.0/legalcode). This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this author at the Faculdade de Engenharia de Alimentos, Universidade Federal do Pará (UFPA) – Rua Augusto Corrêa, 01, Postal code: 66075-110, Belém, PA, Brazil; Tel: +55-91-3201-8994;

Email: rspena@ufpa.br

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 11-09-2018 |

Original Manuscript | Moisture Sorption Behavior of Cupuassu Powder | |

1. INTRODUCTION

Cupuassu (Theobroma grandiflorum) is a tropical fruit native of the Amazon region, which presents citrus pulp with high fiber content and strong aroma. This fruit is considered an excellent raw material to be used in the food industry due to its variety of food applications and nutritional benefits attributed to the presence of ascorbic acid and total phenolics [1Faber MA, Yuyama LKO. Nectar mix functional based on Amazonian fruits. J Cell Sci Ther 2015; 6(1): 1-7., 2Costa MP, Monteiro MLG, Frasao BS, et al. Consumer perception, health information, and instrumental parameters of cupuassu (Theobroma grandiflorum) goat milk yogurts. J Dairy Sci 2017; 100(1): 157-68.

[http://dx.doi.org/10.3168/jds.2016-11315] [PMID: 27816243] ]. Thus, the cupuassu has a high economic potential and it can be used in the development of new functional ingredients for food enrichment [3Salgado JM, Rodrigues BS, Donado-Pestana CM, dos Santos Dias CT, Morzelle MC. Cupuassu (Theobroma grandiflorum) peel as potential source of dietary fiber and phytochemicals in whole-bread preparations. Plant Foods Hum Nutr 2011; 66(4): 384-90.

[http://dx.doi.org/10.1007/s11130-011-0254-0] [PMID: 21948632] ]. An alternative for the elaboration of new products is the use of specific processes such as spray drying to obtain powdered fruit, which guarantees the product’s stability by the reduction of the water activity, aw [4Santana AA, Oliveira RA, Kurozawa LE, Park KJ. Microencapsulation of pequi pulp by spray drying: Use of modified starches as encapsulating agent. Eng Agric 2014; 34(5): 980-91.

[http://dx.doi.org/10.1590/S0100-69162014000500017] ] and practically does not compromise its sensorial and physicochemical characteristics, leading to the production of good quality foods [5Pena RS, Mendonça NB, Almeida MDC. Hygroscopic behavior of powered acai. Rev Bras Prod Agroind 2010; 12(2): 153-61.

[http://dx.doi.org/10.15871/1517-8595/rbpa.v12n2p153-161] ].

However, powdered products obtained from fruits are generally very hygroscopic [4Santana AA, Oliveira RA, Kurozawa LE, Park KJ. Microencapsulation of pequi pulp by spray drying: Use of modified starches as encapsulating agent. Eng Agric 2014; 34(5): 980-91.

[http://dx.doi.org/10.1590/S0100-69162014000500017] ], which may compromise their physical, chemical and microbiological stability. The knowledge of the hygroscopic behavior of powdered products can be carried out using the Moisture Sorption Isotherms (MSI) [6Costa LM, Resende O, Oliveira DEC, Sousa KA. Isotherms and isosteric heat in the seeds of Buchenavia capitata (Vahl) Eichler. Rev Cienc Agron 2015; 46(3): 516-23.

[http://dx.doi.org/10.5935/1806-6690.20150033] ], that describe the relationship between the equilibrium moisture content of the food material and its aw, at a given temperature [7Yogendrarajah P, Samapundo S, Devlieghere F, Saeger S, Meulenaer B. Moisture sorption isotherms and thermodynamic properties of whole black peppercorns (Piper nigrum L.). Lebensm Wiss Technol 2015; 64: 177-88.

[http://dx.doi.org/10.1016/j.lwt.2015.05.045] ]. The adsorption curve is related to the moisture gain, while the desorption represents the moisture losses of a product [5Pena RS, Mendonça NB, Almeida MDC. Hygroscopic behavior of powered acai. Rev Bras Prod Agroind 2010; 12(2): 153-61.

[http://dx.doi.org/10.15871/1517-8595/rbpa.v12n2p153-161] ]. The difference between the curves is called hysteresis and its effect may occur due to several factors, such as capillary condensation, changes in the physical structure of the material, surface impurities and phase change [8Paglarini CS, Silva FS, Porto AG, Piasson D, Santos P. Hysteresis of the sorption isotherms of mango pulp (Mangifera indica L.) manteiga variety. Rev Bras Eng Agric Ambient 2012; 17(3): 299-305.

[http://dx.doi.org/10.1590/S1415-43662013000300008] ]. Therefore, moisture sorption isotherms are considered important thermodynamic tools and provided useful information for food processing operations such as drying, packaging and storage [9Muzaffar K, Kumar P. Moisture sorption isotherms and storage study of spray dried tamarind pulp powder. Powder Technol 2016; 291: 322-7.

[http://dx.doi.org/10.1016/j.powtec.2015.12.046] ]. The isotherms are used to calculate the drying time, to predict ingredients behavior in mixtures, for packaging selection, for modeling the moisture changes during storage and to estimate shelf life stability; these as particularly important factors mainly for powdered foods [10Viganó J, Azuara E, Telis VRN, Beristain CI, Jiménez M, Telis-Romero J. Role of enthalpy and entropy in moisture sorption behavior of pineapple pulp powder produced by different drying methods. Thermochim Acta 2012; 528: 63-71.

[http://dx.doi.org/10.1016/j.tca.2011.11.011] ].

Numerous mathematical models have been proposed to describe food moisture sorption behaviors. Some of these models are based on theories of the sorption mechanism; others are semi-empirical or purely empirical. The theoretical models of BET [11Brunauer S, Emmet PH, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc 1938; 60(2): 309-19.

[http://dx.doi.org/10.1021/ja01269a023] ] (based on monolayer) and GAB (based on a multilayer and condensed film) [12Maroulis ZB, Tsami E, Arinos-Kouris D, Saravacos GD. Application of the GAB model to the sorption isotherms for dried fruits. J Food Eng 1988; 7(1): 63-78.

[http://dx.doi.org/10.1016/0260-8774(88)90069-6] ]; semi-empirical of Halsey [13Halsey G. Physical desorption on non-uniforme surfaces. J Chem Phys 1948; 16(10): 931-7.

[http://dx.doi.org/10.1063/1.1746689] ] and Henderson [14Henderson SM. A basic concept of equilibrium moisture. Agric Eng 1952; 33(1): 29-32.]; and empirical of Oswin [15Oswin CR. The kinetics of package life. III isotherm. J Chem Technol Biotechnol 1946; 65(12): 419-21.

[http://dx.doi.org/10.1002/jctb.5000651216] ] and Peleg [16Peleg M. Assessment of a semi-empirical four parameter general model for sigmoid moisture sorption isotherms. J Food Process Eng 1993; 16: 21-37.

[http://dx.doi.org/10.1111/j.1745-4530.1993.tb00160.x] ], are commonly used for MSI prediction of powdered products.

The GAB model has a theoretical background since it is a refinement of the physical adsorption theory of Langmuir and BET. With three parameters, the GAB model can represent the experimental moisture sorption data of foods in the water activity range of greater practical interest [17Wolf W, Spiess WEL, Jung G. Standardization of isotherm measurements properties of water in foods in relation to food quality and stability 1985; 661-79.]. The GAB model has been recommended by the European Project Group COST 90 on Physical Properties of Foods as the fundamental equation to characterize the water sorption of food materials [17Wolf W, Spiess WEL, Jung G. Standardization of isotherm measurements properties of water in foods in relation to food quality and stability 1985; 661-79.]. On the other hand, the Peleg model is a four-parameter model, which is a purely empirical equation without a theoretical background. However, those models have shown goodness fit for the prediction of the moisture sorption isotherms of fruits powders [18Rodriguez-Bernal JM, Flores-Andrade E, Lizarazo-Morales C, et al. Moisture adsorption isotherms of the borojo fruit (Borojoa patinoi Cuatrecasas) and gum arabic powders. Food Bioprod Process 2015; 94: 187-98.

[http://dx.doi.org/10.1016/j.fbp.2015.03.004] -21Tao Y, Wu Y, Yang J, et al. Thermodynamic sorption properties, water plasticizing effect and particle characteristics of blueberry powders produced from juices, fruits and pomaces. Powder Technol 2018; 323: 208-18.

[http://dx.doi.org/10.1016/j.powtec.2017.09.033] ].

Despite the availability of the substantial number of equations, no single equation has the ability to describe accurately the moisture sorption behavior of food products over the entire range of Relative Humidity (RH) and that’s because water is associated with the food matrix by different mechanisms for different values of aw [7Yogendrarajah P, Samapundo S, Devlieghere F, Saeger S, Meulenaer B. Moisture sorption isotherms and thermodynamic properties of whole black peppercorns (Piper nigrum L.). Lebensm Wiss Technol 2015; 64: 177-88.

[http://dx.doi.org/10.1016/j.lwt.2015.05.045] ]. According to Lomauro et al. [22Lomauro CJ, Bakshi AS, Labuza TP. Evaluation of food moisture sorption isotherm equations. Part II: Milk, Coffee, Tea, Nuts, Oilseeds, Spices and Starchy foods. Lebensm Wiss Technol 1985; 18(2): 118-24.], detailed research in the literature showed that MSI of foods could be described by more than one mathematical model. Therefore, it is necessary to select the model that best fits the moisture sorption data for each specific product.

Studies about the hygroscopic behavior of cupuassu powder containing maltodextrin as drying agent are not available in the literature, which indicates the need of studies to verify the behavior of this product when maltodextrin is added in its composition. In this context, the aim of this work was to determine the adsorption and desorption isotherms of the product, choosing the appropriate packaging and storage conditions; as well as fitting different mathematical models to the experimental data, to select the model that best describes the moisture sorption phenomenon of the powder product.

2. MATERIALS AND METHODS

2.1. Materials

The cupuassu pulp was supplied by the Mixed Agricultural Cooperative of Tomé-Açu (CAMTA), located in the city of Tomé-Açu, Pará, Brazil (02° 25' 08” S and 48° 09' 08” W). The pulp was stored in polyethylene bags (1 kg), frozen at -18°C, and transported to the Federal University of Pará (UFPA) (01° 27' 21” S and 48° 30' 16” W). For the experiments, the pulp was thawed under refrigeration (≈ 4°C) and then brought to room temperature (≈ 25°C). Maltodextrin with a dextrose equivalent of 20 (Maltogill 20, Cargill Agrícola SA, Uberlândia, Brazil) was used as a drying agent.

2.2. Preparation of Cupuassu Powder

The cupuassu powder was obtained in a mini spray dryer (Büchi B-290, Büchi Labortechnik AG, Flawil, Switzerland) at the drying laboratory of the Federal University of Pará (UFPA) (01° 27' 21” S and 48° 30' 16” W). The mixture (pulp:water, ratio 1:1 w/w) was homogenized in a colloidal mill (Brasil 56-RC-6332, São Paulo, Brazil) for 3 min and filtrated through 0.30 mm mesh. Then, 40% maltodextrin was added under the 6.84% total solids content of the filtered mixture. The spray dryer was fed with the formulation into the chamber by a peristaltic pump, using a feed flow rate of 7.5 mL/min and feed temperature of 25°C. The equipment was programmed to operate with nozzle internal diameter of 0.7 mm, parallel current flow, aspiration air flow in 100%, compressed air pressure of 0.8 MPa, drying air flow rate of 35 m3/h and inlet and outlet air temperatures of 150 and 93°C, respectively.

2.3. Powder Analysis

The physicochemical properties of cupuassu powder were determined according to the methods proposed by the AOAC [23AOAC. Association of Official Analytical Chemists Official methods of analysis 16. 1997.]: moisture in a vacuum oven at 70°C (Marconi MA030/12, São Paulo, Brazil) (method 920.151); ashes (method 940.26); protein (method 920.152) (nitrogen-protein conversion factor of 6.25); lipids (method 963.15); total and reducing sugars (method 920.183b); total titratable acidity (method 942.15A); pH in a potentiometer (Hanna HI 2221, Woonsocket, USA) (method 981.12); and Ascorbic Acid content (AA) (method 967.21). Other analyses were also performed, such as: total phenolic compounds (TPC) according to the methodology described by Singleton and Rossi [24Singleton VL, Rossi JA. Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Vitic 1965; 16: 144-58.], using a spectrophotometer (Pharmacia Biotech Ultrospec 2000, Michigan, USA) at a wave-length of 760 nm and the result was expressed as mg of gallic acid equivalents (GAE) per gram of sample; total soluble solids by direct reading in a digital refractometer (Quimis Q767BD, Diadema, São Paulo, Brazil); water activity (aw) by direct reading in a digital thermohygrometer (Aqualab 4TEV, Decagon, Pullman, USA) at 25°C; and color parameter for L* (lightness), a* (redness\greenness), b* (yellowness\ blueness), C* (chroma – color intensity), and h° (hue angle – values of 0°, 90°, 180°, and 270° denote pure red, pure yellow, pure green, and pure blue colors, respectively) was measured using a digital colorimeter (Konica Minolta CR-400, Osaka, Japan) calibrated with white plate. All analyses were carried out in triplicate.

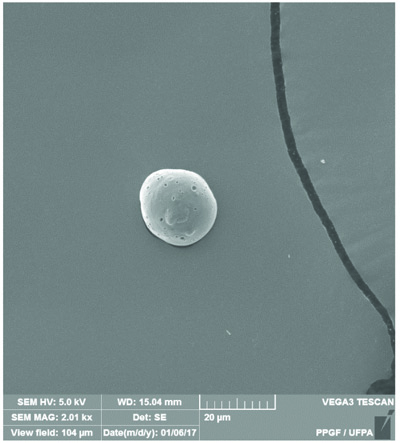

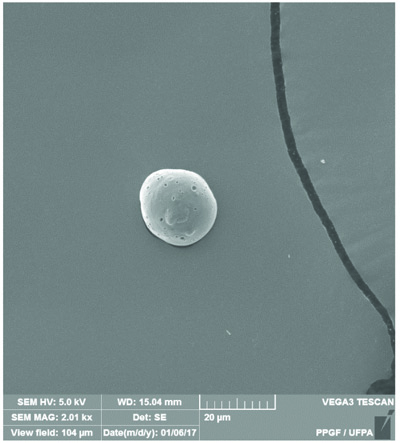

2.4. Powder Morphology

Powder morphology was evaluated by Scanning Electron Microscopy (SEM) in the Nanomanipulation Laboratory (PPGF/UFPA). The samples were fixated onto stubs with conventional conductive double-sided adhesive tape and metallized with a gold/palladium allow in a mini sputter coater (Quorum Technologies SC7620, Kent, UK) using 5 mA current for 120s. Next, the samples were analyzed in a scanning electron microscope (Tescan Vega3, Brno, Czech Republic) using electron beam current of 85-90 µA, 5 Kv acceleration voltage, approximately 15 mm working distance (WD), and magnification of 2000x.

2.5. Determination of Moisture Sorption Isotherms

The adsorption and desorption isotherms were obtained at 25°C in a Vapor Sorption Analyzer (VSA) equipment, using the DVS (Dynamic Vapor Sorption) method, which is based on the readings of sample mass and aw successively until the pre-established equilibrium condition is reached. For the construction of the isotherms, a sample of cupuassu powder was initially stored in a desiccator with silica gel under vacuum and at 25°C for 24 hours to ensure aw < 0.1 in the sample [25Souza TCL, Souza HA, Pena RS. Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Viticult 1965; 16: 144-58.

[http://dx.doi.org/10.1002/star.201200184] ]. After this step, approximately 1 g of the sample was weighed in a stainless steel capsule, in the analytical microbalance of the VSA. The data were obtained in an adsorption-desorption cycle, for a range of 0.1 to 0.9 aw. The equilibrium condition was determined when the mass change and the time variation (Δm/Δt), between consecutive readings, reached a value lower than 0.05. After the analysis, the dry mass of the sample was determined in a vacuum oven at 70°C [23AOAC. Association of Official Analytical Chemists Official methods of analysis 16. 1997.].

2.6. Determination of Monolayer Moisture Content

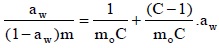

The monolayer moisture content (mo) was calculated using the BET linear equation (Eq. 1) [11Brunauer S, Emmet PH, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc 1938; 60(2): 309-19.

[http://dx.doi.org/10.1021/ja01269a023] ].

|

(1) |

where m = equilibrium moisture content (g H2O/100 g d.b.); aw = water activity (dimensionless), mo = monolayer moisture content (g H2O/100 g d.b.); and C = constant related to the sorption heat.

2.7. Mathematical Modeling of the Sorption Isotherms

The mathematical models proposed by Halsey [13Halsey G. Physical desorption on non-uniforme surfaces. J Chem Phys 1948; 16(10): 931-7.

[http://dx.doi.org/10.1063/1.1746689] ], Henderson [14Henderson SM. A basic concept of equilibrium moisture. Agric Eng 1952; 33(1): 29-32.], Oswin [15Oswin CR. The kinetics of package life. III isotherm. J Chem Technol Biotechnol 1946; 65(12): 419-21.

[http://dx.doi.org/10.1002/jctb.5000651216] ], Peleg [16Peleg M. Assessment of a semi-empirical four parameter general model for sigmoid moisture sorption isotherms. J Food Process Eng 1993; 16: 21-37.

[http://dx.doi.org/10.1111/j.1745-4530.1993.tb00160.x] ] and GAB described by Maroulis et al. [12Maroulis ZB, Tsami E, Arinos-Kouris D, Saravacos GD. Application of the GAB model to the sorption isotherms for dried fruits. J Food Eng 1988; 7(1): 63-78.

[http://dx.doi.org/10.1016/0260-8774(88)90069-6] ] (Table 1) were fitted by nonlinear regression analysis to the experimental sorption data of the product, using the software Statistica 7.0.

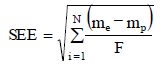

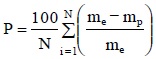

The goodness of the fit of each model was evaluated in terms of maximum coefficient of determination (R2), minimum standard error of estimate (SEE) (Equation 2) and minimum mean absolute percentage error (P) (Equation 3). According to Lomauro et al. [22Lomauro CJ, Bakshi AS, Labuza TP. Evaluation of food moisture sorption isotherm equations. Part II: Milk, Coffee, Tea, Nuts, Oilseeds, Spices and Starchy foods. Lebensm Wiss Technol 1985; 18(2): 118-24.], if the P value is less than 10%, the model is acceptable.

|

(2) |

|

(3) |

where N = number of observations; me = experimental value of equilibrium moisture content (g H2O/100 g d.b.); mp = predicted value of equilibrium moisture content (g H2O/100 g d.b.); and F = degree of freedom of the regression model.

3. RESULTS AND DISCUSSION

3.1. Characterization of Cupuassu Powder

The cupuassu powder composition, physicochemical characterization and color parameters are presented in Table 2.

The powder presented high acidity, low moisture and low aw, which allows the product to present greater stability to degradation processes, since, the lower availability of water and the pH limit the microbial growth [26Castro TMN, Zamboni PV, Dovadoni S, Cunha Neto A, Rodrigues LJ. Parameters of quality of frozen fruit. Rev Inst Adolfo Lutz 2015; 74(4): 426-36.], and consequently, prevent the deterioration of the product during the storage. Additionally, the low fat and high protein contents; besides, the presence of vitamin C and phenolic compounds are important attributes in the product. The major constituent of the product was sugar, which is attributed to the addition of maltodextrin. In turn, despite the addition of maltodextrin, the characteristic yellowish-white color of the pulp was maintained in the powdered cupuassu. In other words, the white coloration of the added maltodextrin did not promote the depreciation of the characteristic color of the product. Similar behavior was observed for Gac fruit aril powder by Kha et al. [27Kha TC, Nguyen MH, Roach PD. Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J Food Eng 2010; 98(3): 385-92.

[http://dx.doi.org/10.1016/j.jfoodeng.2010.01.016] ].

The scanning electromicrograph of the cupuassu powder (Fig. 1 ) shows that the product presents spherical particles with some small orifices (pore). Porous microspheres affect protection of the active material and facilitate the moisture gain since the water can penetrate the pores more easily [28Malik SA, Ng WH, Bowen J, et al. Electrospray synthesis and properties of hierarchically structured PLGA TIPS microspheres for use as controlled release technologies. J Colloid Interface Sci 2016; 467: 220-9.

) shows that the product presents spherical particles with some small orifices (pore). Porous microspheres affect protection of the active material and facilitate the moisture gain since the water can penetrate the pores more easily [28Malik SA, Ng WH, Bowen J, et al. Electrospray synthesis and properties of hierarchically structured PLGA TIPS microspheres for use as controlled release technologies. J Colloid Interface Sci 2016; 467: 220-9.

[http://dx.doi.org/10.1016/j.jcis.2016.01.021] [PMID: 26803601] ].

|

Fig. (1) Scanning electron microscopy images of cupuassu powder containing 40% maltodextrin. |

|

Fig. (2) Sorption isotherms of cupuassu powder at 25°C and the models of Peleg and GAB fitted to the adsorption and desorption data. |

3.2. Moisture Sorption Isotherms

Fig. (2 ) shows the adsorption and desorption data for the cupuassu powder at 25°C. According to the adsorption data, the product will exhibit microbiological stability (aw < 0.6) [29Labuza TP. The effect of water activity on reaction kinetics of food deterioration. Food Technol 1980; 34: 36-59.] if its moisture content remains below 13 g H2O/100 g d.b., which corresponds to product moisture of 11.5 g H2O/100 g. According to the BET equation, the moisture values equivalent to the monolayer (mo) were 4.3 g H2O/100 g d.b. for adsorption and 7.6 g H2O/100 g d.b. for desorption (R2 > 0.98). The mo adsorption value indicates the highest stability moisture level of the powder product. On the other hand, based on the mo value for the desorption process, it is recommended not to dry the cupuassu pulp added of 40% maltodextrin at moisture levels below 7.6 g H2O/100 g d.b, to avoid unnecessary energy loss. Since, at this moisture level, the aw of the product will be less than 0.6, so its microbiological stability will be ensured.

) shows the adsorption and desorption data for the cupuassu powder at 25°C. According to the adsorption data, the product will exhibit microbiological stability (aw < 0.6) [29Labuza TP. The effect of water activity on reaction kinetics of food deterioration. Food Technol 1980; 34: 36-59.] if its moisture content remains below 13 g H2O/100 g d.b., which corresponds to product moisture of 11.5 g H2O/100 g. According to the BET equation, the moisture values equivalent to the monolayer (mo) were 4.3 g H2O/100 g d.b. for adsorption and 7.6 g H2O/100 g d.b. for desorption (R2 > 0.98). The mo adsorption value indicates the highest stability moisture level of the powder product. On the other hand, based on the mo value for the desorption process, it is recommended not to dry the cupuassu pulp added of 40% maltodextrin at moisture levels below 7.6 g H2O/100 g d.b, to avoid unnecessary energy loss. Since, at this moisture level, the aw of the product will be less than 0.6, so its microbiological stability will be ensured.

The sorption isotherm presented type III behavior, which is characteristic of products rich in sugars, according to the classification of Brunauer et al. [11Brunauer S, Emmet PH, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc 1938; 60(2): 309-19.

[http://dx.doi.org/10.1021/ja01269a023] ]. This is attributed to the presence of total sugars as the major constituent of the product, which is especially related to the addition of maltodextrin. Similar behavior was reported previously in atomized products as syrup powder [30Farahnaky A, Mansoorib N, Majzoobia M, Badii F. Physicochemical and sorption isotherm properties of date syrup powder: Antiplasticizing effect of maltodextrin. Food Bioprod Process 2016; 98: 133-41.

[http://dx.doi.org/10.1016/j.fbp.2016.01.003] ], strawberry powder [31Oliveira MIS, Tonon RV, Nogueira RI, Cabral LMC. Stability of spray-dryed strawberry pulp produced with different carrier agents. Braz J Food Technol 2013; 16(4): 310-8.

[http://dx.doi.org/10.1590/S1981-67232013005000037] ] and orange juice powder [32Islam MZ, Kitamura Y, Yamano Y, Kitamura M. Effect of vacuum spray drying on the physicochemical properties, water sorption and glass transition phenomenon of orange juice powder. J Food Eng 2016; 169: 131-40.

[http://dx.doi.org/10.1016/j.jfoodeng.2015.08.024] ], all using the maltodextrin as a drying agent. According to Ghorab et al. [33Ghorab MK, Toth SJ, Simpson GJ, Mauer LJ, Taylor LS. Water-solid interactions in amorphous maltodextrin-crystalline sucrose binary mixtures. Pharm Dev Technol 2014; 19(2): 247-56.

[http://dx.doi.org/10.3109/10837450.2013.775157] [PMID: 23477494] ], MSI of amorphous materials such as maltodextrin often show type II or type III profiles.

The adsorption isotherm showed a linear behavior until 0.5 aw level, and from this point, it assumed an exponential behavior with a progressive increase of the product’s moisture content. According to this behavior, the product requires greater care, when stored and/or handled in environments with RH above 50%, since it is more susceptible to humidification, and therefore, more favorable to degradation processes (caused by undesirable reactions) and to microorganisms’ growth. Thus, to avoid excessive moisture gain, it is necessary the use of impermeable packaging or packaging with low water vapor permeability.

Another feature of the product is the presence of bioactive compounds such as vitamin C (105.84 mg/100 g) and total phenolics (133.8 mg GAE/100 g), which are very susceptible to oxidative processes. Therefore, to minimize such processes, it is strongly indicated that the packages also have impermeability to air and does not allow light to pass through. In this context, Polyethylene Terephthalate with Aluminum foil and Low-Density Polyethylene (PET/Al/LDPE) film presents as an ideal packaging material for the product [34Alves RMV, Ito D, Carvalho JLV, Melo WF, Godoy RLO. Stability of biofortified sweet potato flour. Braz J Food Technol 2012; 15(1): 59-71.

[http://dx.doi.org/10.1590/S1981-67232012000100007] ].

A type of packaging used to store powder juice presents 70 mm × 70 mm dimensions and holds 25 g of the product. Using these parameters, the equation proposed by Costa et al. [35Costa TS, Carmo JR, Pena RS. Powdered tucupi condiment: Sensory and hygroscopic evaluation. Food Sci Technol 2018; 38(1): 33-40.

[http://dx.doi.org/10.1590/1678-457x.36816] ] was used to estimate the storage time required for the product to reach a critical moisture level (13 g H2O/100 g d.b. at aw = 0.6). It was considered the minimum value of water vapor permeability of 0.01 g H2O/m2.day for a PET/Al/LDPE film with 86 µm thickness, being 11 µm of PET, 9 µm of Al and 66 µm of LDPE, when exposed to an environment at 38°C and RH of 90% [34Alves RMV, Ito D, Carvalho JLV, Melo WF, Godoy RLO. Stability of biofortified sweet potato flour. Braz J Food Technol 2012; 15(1): 59-71.

[http://dx.doi.org/10.1590/S1981-67232012000100007] ]. On the regarded conditions, the estimated storage time for the cupuassu powder with 3% moisture is over two years.

Fig. (2 ) also shows the beginning of hysteresis effect at the capillary condensation region (aw ≈ 0.7), which extends to the monolayer region (aw ≈ 0.1). However, the hysteresis loop did not close in this region, which can be attributed to loss of flowability and crystallinity of the product during the adsorption process. The addition of maltodextrin increases the glass transition temperature (Tg) of the product and generally tends to form amorphous solids. On the other hand, the increase in moisture content decreases the Tg of the product due to the water plasticizing effect. The amorphous solids can undergo physical changes such as stickiness, collapse, caking, tackiness, agglomeration, crystallization and compaction during processing, handling and storage. These physical changes in dehydrated products are related to their Tg. Below the Tg, the food is expected to be stable, whereas above this temperature, the rate of physical, chemical and biological changes of the product increases with the storage temperature [33Ghorab MK, Toth SJ, Simpson GJ, Mauer LJ, Taylor LS. Water-solid interactions in amorphous maltodextrin-crystalline sucrose binary mixtures. Pharm Dev Technol 2014; 19(2): 247-56.

) also shows the beginning of hysteresis effect at the capillary condensation region (aw ≈ 0.7), which extends to the monolayer region (aw ≈ 0.1). However, the hysteresis loop did not close in this region, which can be attributed to loss of flowability and crystallinity of the product during the adsorption process. The addition of maltodextrin increases the glass transition temperature (Tg) of the product and generally tends to form amorphous solids. On the other hand, the increase in moisture content decreases the Tg of the product due to the water plasticizing effect. The amorphous solids can undergo physical changes such as stickiness, collapse, caking, tackiness, agglomeration, crystallization and compaction during processing, handling and storage. These physical changes in dehydrated products are related to their Tg. Below the Tg, the food is expected to be stable, whereas above this temperature, the rate of physical, chemical and biological changes of the product increases with the storage temperature [33Ghorab MK, Toth SJ, Simpson GJ, Mauer LJ, Taylor LS. Water-solid interactions in amorphous maltodextrin-crystalline sucrose binary mixtures. Pharm Dev Technol 2014; 19(2): 247-56.

[http://dx.doi.org/10.3109/10837450.2013.775157] [PMID: 23477494] , 36Tonon RV, Baroni AF, Brabet C, Gibert O, Pallet D, Hubinger MD. Water sorption and glass transition temperature of spray dried acai (Euterpe oleracea Mart.) juice. J Food Eng 2009; 94(3-4): 215-22.

[http://dx.doi.org/10.1016/j.jfoodeng.2009.03.009] , 37Fang Z, Bhandari B. Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem 2011; 129(3): 1139-47.

[http://dx.doi.org/10.1016/j.foodchem.2011.05.093] [PMID: 25212349] ].

3.3. Moisture Sorption Isotherms Modeling

The coefficient of determination (R2), standard error of estimate (SEE) and mean absolute percentage error (P), as well as the coefficients of the mathematical models fitted to the moisture sorption data of the powdered product at 25°C are shown in Table 3. According to the results, the Peleg and GAB models can predict with good precision the MSI of the cupuassu powder (Fig. 2 ), since the R2 maximum, SEE minimum and P ≤ 10% indicated the best fit to both adsorption and desorption data of the product. Comparable results were observed by Farahnaky et al. [30Farahnaky A, Mansoorib N, Majzoobia M, Badii F. Physicochemical and sorption isotherm properties of date syrup powder: Antiplasticizing effect of maltodextrin. Food Bioprod Process 2016; 98: 133-41.

), since the R2 maximum, SEE minimum and P ≤ 10% indicated the best fit to both adsorption and desorption data of the product. Comparable results were observed by Farahnaky et al. [30Farahnaky A, Mansoorib N, Majzoobia M, Badii F. Physicochemical and sorption isotherm properties of date syrup powder: Antiplasticizing effect of maltodextrin. Food Bioprod Process 2016; 98: 133-41.

[http://dx.doi.org/10.1016/j.fbp.2016.01.003] ] for MSI of the powdered syrup. Several studies report the higher efficiency of the GAB model on predicting the MSI of powdered fruits, for example, a commercial cupuassu powder without drying agent [38Silva AE, Silva LHM, Pena RS. Hygroscopic behavior of açaí and cupuaçu powders. Food Sci Technol (Campinas) 2008; 28(4): 895-901.

[http://dx.doi.org/10.1590/S0101-20612008000400020] ], strawberry pulp powder [31Oliveira MIS, Tonon RV, Nogueira RI, Cabral LMC. Stability of spray-dryed strawberry pulp produced with different carrier agents. Braz J Food Technol 2013; 16(4): 310-8.

[http://dx.doi.org/10.1590/S1981-67232013005000037] ], mango pulp powder [39Moreira TB, Rocha EMFF, Afonso MRA, Costa JMC. Behavior of adsorption isotherms of freeze-dried mango pulp powder. Rev Bras Eng Agric Ambient 2013; 17(10): 1093-8.

[http://dx.doi.org/10.1590/S1415-43662013001000011] ], yellow mombin pulp powder [40Oliveira GS, Costa JMC, Afonso MRA. Characterization and hygroscopic behavior of lyophilized yellow mombin in pulp powder. Rev Bras Eng Agric Ambient 2014; 18(10): 1059-64.

[http://dx.doi.org/10.1590/1807-1929/agriambi.v18n10p1059-1064] ], tamarind pulp powder [9Muzaffar K, Kumar P. Moisture sorption isotherms and storage study of spray dried tamarind pulp powder. Powder Technol 2016; 291: 322-7.

[http://dx.doi.org/10.1016/j.powtec.2015.12.046] ], among others. In turn, there are few reports of the Peleg model application in the MSI prediction of powdered fruits. According to Silva et al. [41Silva RNG, Figueirêdo RMF, Queiroz AJM, Feitosa RM. Moisture adsorption isotherms of umbu-cajá powder. Rev Ed Agric Sup 2015; 30(1): 33-6.], the Peleg model resulted in better fits to the experimental data of umbu-cajá powder.

CONCLUSION

The cupuassu powder containing 40% maltodextrin presents type III sorption isotherms. The hygroscopic evaluation indicated that the product should preferably be stored in an environment with an RH below 50% and while the product moisture remains below 11.5%, it presents microbiological stability. Additionally, the monolayer values, for adsorption, indicate that the moisture level of greater product degradation stability is 4.3%, while the desorption isotherm indicates that the cupuassu pulp should not be dried at moisture content lower than 7.6%, to avoid unnecessary energy loss. It is recommended that the cupuassu powder should be stored in a packaging impermeable to water vapor and air, which does not allow the light to pass through; preferably under vacuum or nitrogen atmosphere to minimize the moisture gain and oxidation of the bioactive compounds. The Peleg and GAB models can accurately predict the adsorption and desorption isotherms of the powder product studied.

LIST OF ABBREVIATIONS

| SEM | = Scanning Electron Microscopy |

| PET | = Polyethylene Terephthalate |

| LDPE | = Low-Density Polyethylene |

| SEE | = Standard Error of Estimate |

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

No animals/humans were used for studies that are the basis of this research.

CONSENT FOR PUBLICATION

Not applicable.

FUNDING

The authors are grateful to CNPq/Brazil (Conselho Nacional de Desenvolvimento Científico e Tecnológico) for the scholarship of J. C. P. Pombo and PROPESP/UFPA for the financial support.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The authors are grateful to the financial supporters.

REFERENCES

| [1] | Faber MA, Yuyama LKO. Nectar mix functional based on Amazonian fruits. J Cell Sci Ther 2015; 6(1): 1-7. |

| [2] | Costa MP, Monteiro MLG, Frasao BS, et al. Consumer perception, health information, and instrumental parameters of cupuassu (Theobroma grandiflorum) goat milk yogurts. J Dairy Sci 2017; 100(1): 157-68. [http://dx.doi.org/10.3168/jds.2016-11315] [PMID: 27816243] |

| [3] | Salgado JM, Rodrigues BS, Donado-Pestana CM, dos Santos Dias CT, Morzelle MC. Cupuassu (Theobroma grandiflorum) peel as potential source of dietary fiber and phytochemicals in whole-bread preparations. Plant Foods Hum Nutr 2011; 66(4): 384-90. [http://dx.doi.org/10.1007/s11130-011-0254-0] [PMID: 21948632] |

| [4] | Santana AA, Oliveira RA, Kurozawa LE, Park KJ. Microencapsulation of pequi pulp by spray drying: Use of modified starches as encapsulating agent. Eng Agric 2014; 34(5): 980-91. [http://dx.doi.org/10.1590/S0100-69162014000500017] |

| [5] | Pena RS, Mendonça NB, Almeida MDC. Hygroscopic behavior of powered acai. Rev Bras Prod Agroind 2010; 12(2): 153-61. [http://dx.doi.org/10.15871/1517-8595/rbpa.v12n2p153-161] |

| [6] | Costa LM, Resende O, Oliveira DEC, Sousa KA. Isotherms and isosteric heat in the seeds of Buchenavia capitata (Vahl) Eichler. Rev Cienc Agron 2015; 46(3): 516-23. [http://dx.doi.org/10.5935/1806-6690.20150033] |

| [7] | Yogendrarajah P, Samapundo S, Devlieghere F, Saeger S, Meulenaer B. Moisture sorption isotherms and thermodynamic properties of whole black peppercorns (Piper nigrum L.). Lebensm Wiss Technol 2015; 64: 177-88. [http://dx.doi.org/10.1016/j.lwt.2015.05.045] |

| [8] | Paglarini CS, Silva FS, Porto AG, Piasson D, Santos P. Hysteresis of the sorption isotherms of mango pulp (Mangifera indica L.) manteiga variety. Rev Bras Eng Agric Ambient 2012; 17(3): 299-305. [http://dx.doi.org/10.1590/S1415-43662013000300008] |

| [9] | Muzaffar K, Kumar P. Moisture sorption isotherms and storage study of spray dried tamarind pulp powder. Powder Technol 2016; 291: 322-7. [http://dx.doi.org/10.1016/j.powtec.2015.12.046] |

| [10] | Viganó J, Azuara E, Telis VRN, Beristain CI, Jiménez M, Telis-Romero J. Role of enthalpy and entropy in moisture sorption behavior of pineapple pulp powder produced by different drying methods. Thermochim Acta 2012; 528: 63-71. [http://dx.doi.org/10.1016/j.tca.2011.11.011] |

| [11] | Brunauer S, Emmet PH, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc 1938; 60(2): 309-19. [http://dx.doi.org/10.1021/ja01269a023] |

| [12] | Maroulis ZB, Tsami E, Arinos-Kouris D, Saravacos GD. Application of the GAB model to the sorption isotherms for dried fruits. J Food Eng 1988; 7(1): 63-78. [http://dx.doi.org/10.1016/0260-8774(88)90069-6] |

| [13] | Halsey G. Physical desorption on non-uniforme surfaces. J Chem Phys 1948; 16(10): 931-7. [http://dx.doi.org/10.1063/1.1746689] |

| [14] | Henderson SM. A basic concept of equilibrium moisture. Agric Eng 1952; 33(1): 29-32. |

| [15] | Oswin CR. The kinetics of package life. III isotherm. J Chem Technol Biotechnol 1946; 65(12): 419-21. [http://dx.doi.org/10.1002/jctb.5000651216] |

| [16] | Peleg M. Assessment of a semi-empirical four parameter general model for sigmoid moisture sorption isotherms. J Food Process Eng 1993; 16: 21-37. [http://dx.doi.org/10.1111/j.1745-4530.1993.tb00160.x] |

| [17] | Wolf W, Spiess WEL, Jung G. Standardization of isotherm measurements properties of water in foods in relation to food quality and stability 1985; 661-79. |

| [18] | Rodriguez-Bernal JM, Flores-Andrade E, Lizarazo-Morales C, et al. Moisture adsorption isotherms of the borojo fruit (Borojoa patinoi Cuatrecasas) and gum arabic powders. Food Bioprod Process 2015; 94: 187-98. [http://dx.doi.org/10.1016/j.fbp.2015.03.004] |

| [19] | Langrish TAG. Moisture sorption isotherms and net isosteric heat of sorption for spray-dried pure orange juice powder. Lebensm Wiss Technol 2015; 62(1): 875-82. [http://dx.doi.org/10.1016/j.lwt.2014.09.064] |

| [20] | Kaderides K, Goula AM. Development and characterization of a new encapsulating agent from orange juice by-products. Food Res Int 2017; 100(Pt 1): 612-22. [http://dx.doi.org/10.1016/j.foodres.2017.07.057] [PMID: 28873728] |

| [21] | Tao Y, Wu Y, Yang J, et al. Thermodynamic sorption properties, water plasticizing effect and particle characteristics of blueberry powders produced from juices, fruits and pomaces. Powder Technol 2018; 323: 208-18. [http://dx.doi.org/10.1016/j.powtec.2017.09.033] |

| [22] | Lomauro CJ, Bakshi AS, Labuza TP. Evaluation of food moisture sorption isotherm equations. Part II: Milk, Coffee, Tea, Nuts, Oilseeds, Spices and Starchy foods. Lebensm Wiss Technol 1985; 18(2): 118-24. |

| [23] | AOAC. Association of Official Analytical Chemists Official methods of analysis 16. 1997. |

| [24] | Singleton VL, Rossi JA. Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Vitic 1965; 16: 144-58. |

| [25] | Souza TCL, Souza HA, Pena RS. Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Viticult 1965; 16: 144-58. [http://dx.doi.org/10.1002/star.201200184] |

| [26] | Castro TMN, Zamboni PV, Dovadoni S, Cunha Neto A, Rodrigues LJ. Parameters of quality of frozen fruit. Rev Inst Adolfo Lutz 2015; 74(4): 426-36. |

| [27] | Kha TC, Nguyen MH, Roach PD. Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J Food Eng 2010; 98(3): 385-92. [http://dx.doi.org/10.1016/j.jfoodeng.2010.01.016] |

| [28] | Malik SA, Ng WH, Bowen J, et al. Electrospray synthesis and properties of hierarchically structured PLGA TIPS microspheres for use as controlled release technologies. J Colloid Interface Sci 2016; 467: 220-9. [http://dx.doi.org/10.1016/j.jcis.2016.01.021] [PMID: 26803601] |

| [29] | Labuza TP. The effect of water activity on reaction kinetics of food deterioration. Food Technol 1980; 34: 36-59. |

| [30] | Farahnaky A, Mansoorib N, Majzoobia M, Badii F. Physicochemical and sorption isotherm properties of date syrup powder: Antiplasticizing effect of maltodextrin. Food Bioprod Process 2016; 98: 133-41. [http://dx.doi.org/10.1016/j.fbp.2016.01.003] |

| [31] | Oliveira MIS, Tonon RV, Nogueira RI, Cabral LMC. Stability of spray-dryed strawberry pulp produced with different carrier agents. Braz J Food Technol 2013; 16(4): 310-8. [http://dx.doi.org/10.1590/S1981-67232013005000037] |

| [32] | Islam MZ, Kitamura Y, Yamano Y, Kitamura M. Effect of vacuum spray drying on the physicochemical properties, water sorption and glass transition phenomenon of orange juice powder. J Food Eng 2016; 169: 131-40. [http://dx.doi.org/10.1016/j.jfoodeng.2015.08.024] |

| [33] | Ghorab MK, Toth SJ, Simpson GJ, Mauer LJ, Taylor LS. Water-solid interactions in amorphous maltodextrin-crystalline sucrose binary mixtures. Pharm Dev Technol 2014; 19(2): 247-56. [http://dx.doi.org/10.3109/10837450.2013.775157] [PMID: 23477494] |

| [34] | Alves RMV, Ito D, Carvalho JLV, Melo WF, Godoy RLO. Stability of biofortified sweet potato flour. Braz J Food Technol 2012; 15(1): 59-71. [http://dx.doi.org/10.1590/S1981-67232012000100007] |

| [35] | Costa TS, Carmo JR, Pena RS. Powdered tucupi condiment: Sensory and hygroscopic evaluation. Food Sci Technol 2018; 38(1): 33-40. [http://dx.doi.org/10.1590/1678-457x.36816] |

| [36] | Tonon RV, Baroni AF, Brabet C, Gibert O, Pallet D, Hubinger MD. Water sorption and glass transition temperature of spray dried acai (Euterpe oleracea Mart.) juice. J Food Eng 2009; 94(3-4): 215-22. [http://dx.doi.org/10.1016/j.jfoodeng.2009.03.009] |

| [37] | Fang Z, Bhandari B. Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem 2011; 129(3): 1139-47. [http://dx.doi.org/10.1016/j.foodchem.2011.05.093] [PMID: 25212349] |

| [38] | Silva AE, Silva LHM, Pena RS. Hygroscopic behavior of açaí and cupuaçu powders. Food Sci Technol (Campinas) 2008; 28(4): 895-901. [http://dx.doi.org/10.1590/S0101-20612008000400020] |

| [39] | Moreira TB, Rocha EMFF, Afonso MRA, Costa JMC. Behavior of adsorption isotherms of freeze-dried mango pulp powder. Rev Bras Eng Agric Ambient 2013; 17(10): 1093-8. [http://dx.doi.org/10.1590/S1415-43662013001000011] |

| [40] | Oliveira GS, Costa JMC, Afonso MRA. Characterization and hygroscopic behavior of lyophilized yellow mombin in pulp powder. Rev Bras Eng Agric Ambient 2014; 18(10): 1059-64. [http://dx.doi.org/10.1590/1807-1929/agriambi.v18n10p1059-1064] |

| [41] | Silva RNG, Figueirêdo RMF, Queiroz AJM, Feitosa RM. Moisture adsorption isotherms of umbu-cajá powder. Rev Ed Agric Sup 2015; 30(1): 33-6. |